Operating instructions – Bell & Gossett V57050B SRS Pneumatic Purge Valve User Manual

Page 2

5. Pipe as required to allow gravity flow of sediment and

water, and proper drainage.

6. Apply approximately 2 wraps of PTFE tape to the male end

of 1" field piping as it comes from the SRS and recom-

mended service valve, and install into the inlet of the 1"

FNPT connection of the purge valve. Do the same for the

1" FNPT outlet and run the piping to a nearby drain.

7. Run air for the valve in accordance with local code. Be cer-

tain that the minimum and maximum control pressure for

the air are complied with. Purchase a 1/4" air hose adapter,

apply PTFE tape to the threads, and insert into the 1/4" air

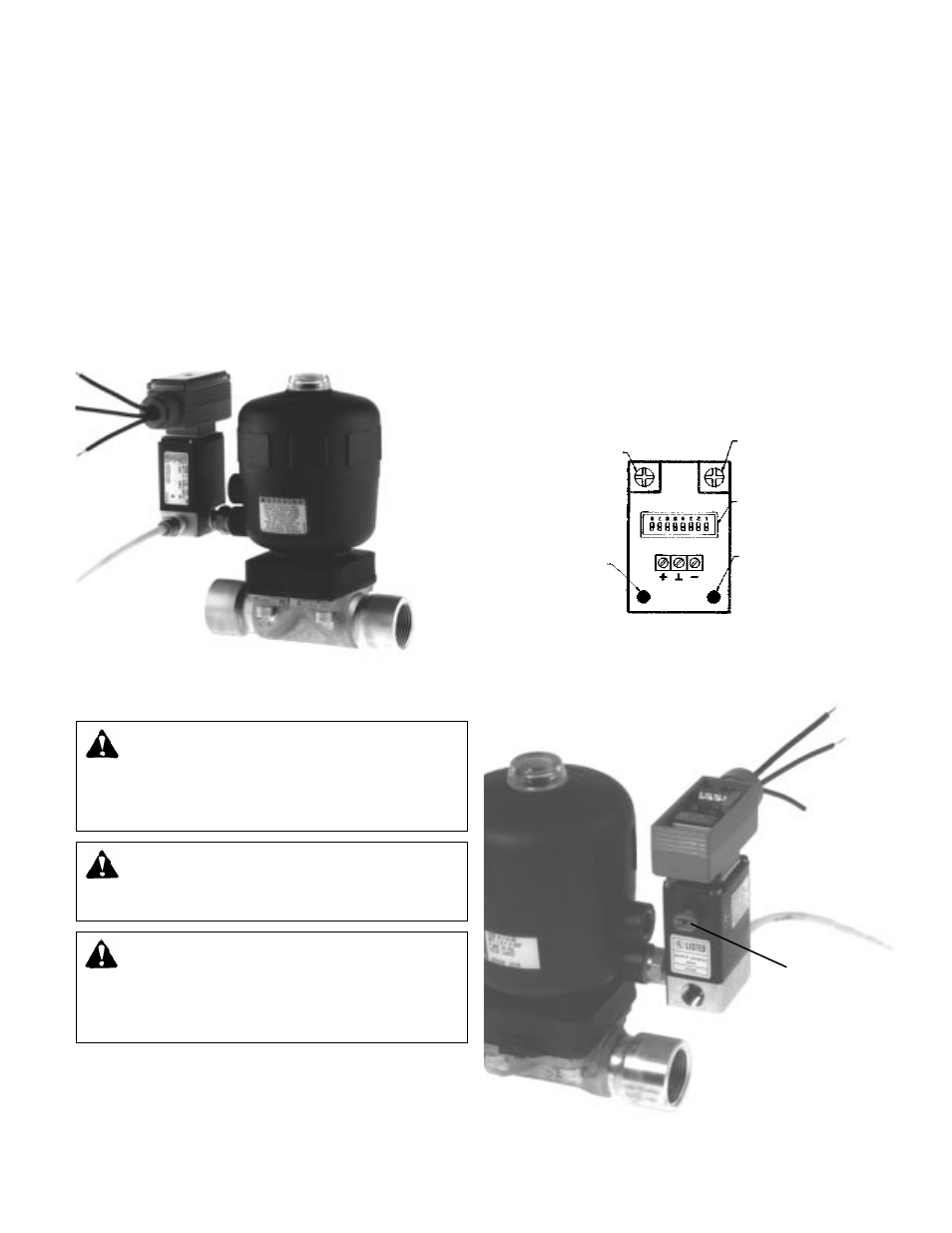

port on the side of the solenoid valve as shown in Figure 2.

Then attach tubing.

8. Install 120V AC to the timer per local code. Remove the

timer cover to expose the 3 terminal strip. Connect 120V

AC to the terminal strip. Attach the middle terminal to

ground. These connections provide the power for the sole-

noid and timer. See Figure 3.

OPERATING INSTRUCTIONS

The timer is factory set as follows:

Cycle Time (how often the valve opens): 4 hrs.

Purge Duration (how long valve remains open per cycle): 10 sec

At start-up, the valve can be manually purged by depressing

the button located on the side of the solenoid. (See Figure 4).

We recommend manually purging the valve approximately

every 30 minutes for 2 hours to determine if the factory setting

is sufficient to handle the sediment problem in the system.

Keep in mind that the first hour of start up will typically have a

greater concentration of sediment than that found after several

hours of operation.

If the factory setting is insufficient, adjustment is made by a

series of DIP switches in the timer. The switches are accessed

by removing the cover of the timer. Figure 3 is a sketch of the

timer assembly, and Figure 5 is a diagram of the DIP switches

and the range of settings available.

TIMER CONNECTIONS & ADJUSTMENTS

WARNING: Water at temperatures above 100°F

(38°C) can be very hazardous. Piping from valve to

drain should be such that there is no risk of exposure of

hot water to personnel or equipment. Failure to follow

these instructions could result in serious personal injury or

death and property damage.

WARNING: Electrical shock and potential circuit

damage. Disconnect power before beginning instal-

lation. Failure to follow these instructions could result in

serious personal injury or death and property damage.

WARNING: Improper wiring and wire can cause

electrical shock and fires. Wiring connections must

be made in accordance with all applicable electrical codes

and ordinances. Use copper wire only. Failure to follow

these instructions could result in serious personal injury or

death and property damage.

2

Figure 2

Pilot Valve

Timer

Valve

Actuator

Manual

Purge

Button

Figure 3

Figure 4

Output

Led

Power

Led

Dip

Switches

Cycle Time

Potentiometer

Duration of

Purge Time

Potentiometer