Maintenance, Operation – Bell & Gossett V1000461 Snap Zone Valve – ½” to 1” User Manual

Page 3

1.

Turn off the power switch that supplies power to the valve.

2.

Squeeze the button on the front of the actuator to remove it from the

valve assembly.

3.

The valve is now fully open and allows gravity circulation through the

system.

After power is restored, follow these instructions to return the valve to normal

operation:

1.

Assemble the actuator to the valve by pressing it back onto the valve

and adapter until it snaps into place.

2.

Turn on the power switch.

Maintenance

Precautions

WARNING:

• All procedures must be performed by qualified personnel.

• When the process fluid is hazardous, thermal (hot or cold), or

corrosive, take extra precautions. Employ the appropriate

safety devices and be prepared to control a process media

leak.

• Always wear protective clothing and equipment to safeguard

the eyes, face, hands, skin, and lungs from the particular fluid

in the line.

Valve inspection

Periodically inspect the valve for signs of leakage or corrosion.

WARNING:

Risk for property damage, serious personal injury or death. You

must replace the valve if corrosion or leakage is found.

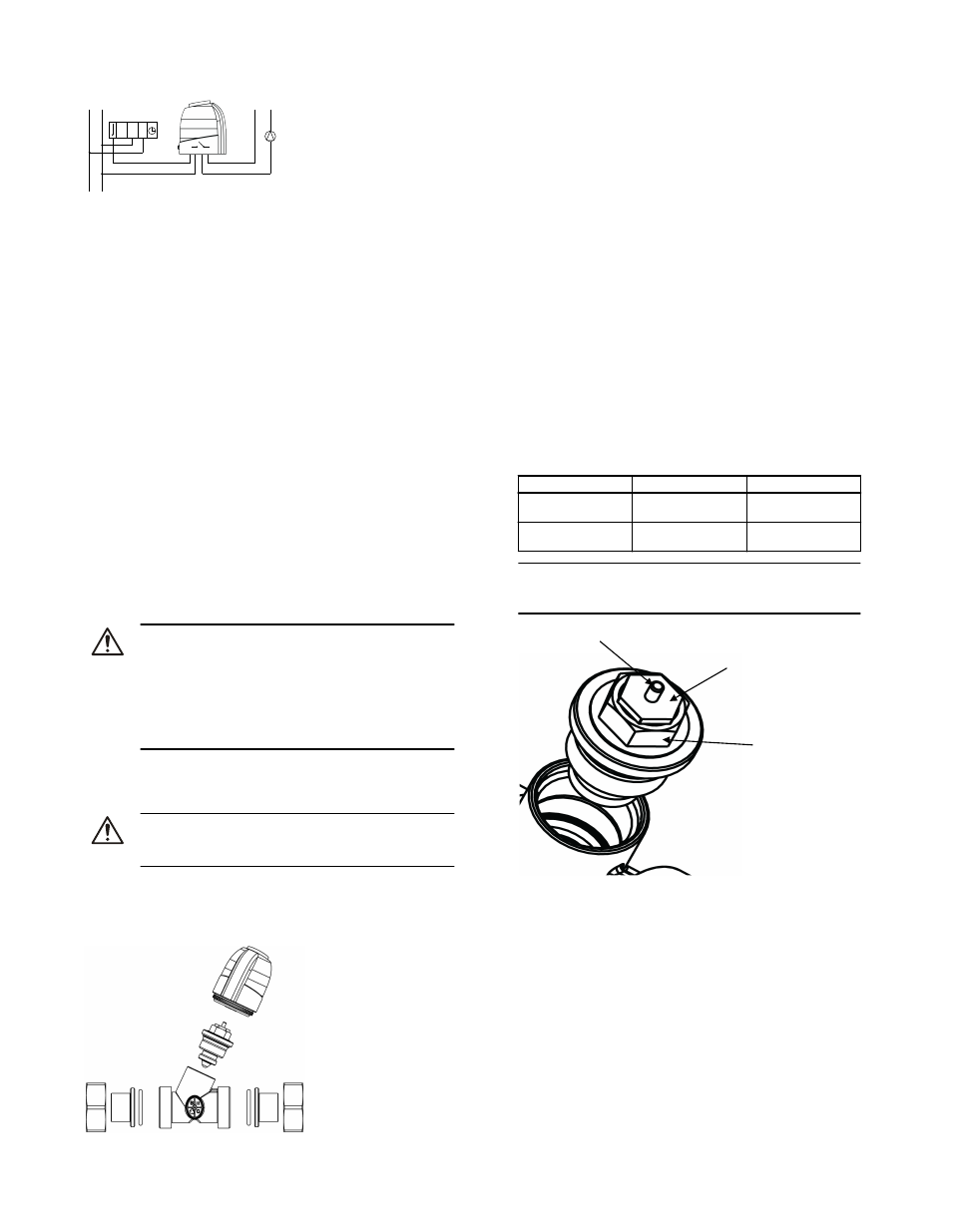

Valve parts view

The exploded view of the snap zone valve will aid in the performance of

service or maintenance.

Remove valve from service

1.

Isolate and drain the zone that you wish to service.

2.

Turn off the power to the valve actuator.

3.

Remove the actuator from the valve by squeezing the button on the

front of the actuator and lifting it up.

4.

Unthread the actuator adapter to reveal the valve bonnet plunger as-

sembly.

5.

The following components can now be inspected and replaced if nec-

essary:

Replace the valve body assembly

1.

Loosen union nuts on both ends of the valve assembly and carefully

remove the valve from the surrounding piping.

2.

Examine the valve body for corrosion or damage. If there is any indi-

cation of corrosion or damage, replace the entire body assembly.

3.

If there are no signs of damage, replace the O-rings and reinstall the

valve body assembly in the line.

Replace the bonnet plunger assembly

1.

With the actuator adapter removed, inspect the valve bonnet plunger

assembly for signs of corrosion, leakage, or damage.

2.

Use a wrench to loosen and remove the bonnet plunger assembly.

3.

Push the valve stem by hand to verify the motion of the plunger.

The bonnet plunger must be replaced if the plunger does not move,

there is corrosion or other visible damage is seen.

4.

Make sure that the male threads of the bonnet plunger assembly and

the female threads of the valve are clean and that there is no debris

present.

5.

When installing the replacement bonnet plunger assembly, tighten the

assembly into the valve body until it is finger tight.

6.

Tighten the assembly to the following specifications:

Component

Seal

Torque

Hex bushing packing

box

O-ring

6.0 ft-lbs. + 1.9 ft-

lbs. / 0

Bonnet plunger as-

sembly

O-ring

25.0 ft-lbs. + 7 ft-

lbs. / 0

NOTICE:

Over application of torque can damage the valve or bonnet plunger as-

sembly.

1

2

3

1.

Valve stem

2.

Hex bushing packing box

3.

Bonnet plunger assembly

Replace the actuator

If the actuator has failed, it can be replaced rather than replacing the entire valve

assembly. Turn off the power switch that supplies power to the valve.

1.

Squeeze the button on the front of the actuator and lift to remove.

2.

Disconnect actuator wiring from the power source and any auxiliary

peripherals.

3.

Assemble the replacement actuator onto the valve by pressing the ac-

tuator onto the valve and adapter until it snaps into place.

4.

Follow the wiring procedures in the installation chapter.

Return the valve to service

1.

Open the supply to return water to the necessary zones.

2.

Open any downstream isolation valves.

3.

Vent the system as necessary.

4.

Restore power to the actuator.

Operation

Manual operation instructions

In the case of a power failure follow these instructions:

Wiring diagram

1

24V

AC

L1 L2

L1

L

L2

N

L2

N

2

3

4

5

6

1.

Thermostat

2.

Brown

3.

Blue

4.

Black

5.

Gray

6.

24V maximum, 3A ohm

resistive load, 1A inductive

load

Attach insulation

To maximize energy savings, attach insulation to the valve after the system

has been balanced. Tape or other acceptable means can be used to secure

the insulation to the valve. The insulation must not cover the actuator.