Installation – Bell & Gossett V1000461 Snap Zone Valve – ½” to 1” User Manual

Page 2

Installation

Installation precautions

CAUTION:

• The valve can be damaged if improper sweating (soldering) is

used with the union connection. Before sweating the union

connection to the valve, remove the union nut and O-ring

from the valve body, then sweat the union tailpiece with

union nut into place.

• Make sure that all connecting pipe work is water tight.

• The use of petroleum based lubricants on valve o-rings will

cause swelling and failure of o-rings. This can cause leakage.

Pipe hanging installations

Be aware of water weight in the valve and connected piping when installing

your system.

NOTICE:

Never use the valve as a form of piping support. Support the valves and

piping according to the local building code. Failure to follow these

instructions may result in property damage.

Install the valve

The snap zone valve can be installed horizontally or vertically. Observe the

following precautions:

• When the valve is installed in a vertical position, the electrical

connections must be at the top of the actuator.

• On chilled water applications, the actuator should be above the pipe

centerline.

• Do not install the valve in a dusty area.

1.

Install the valve in line via the NPT or sweat union connections.

2.

Lubricate the enclosed O-rings with silicone oil or grease before

installation.

3.

Insert the O-rings in the grooves that are provided on the mounting

face of each side of the valve.

4.

Slide the union nuts over the pipe with the open threaded end of the

nut facing the valve.

5.

Thread or sweat the tail pieces for the valve to the adjacent piping.

6.

Tighten union nuts to complete valve assembly to line.

Install NPT connection

1.

Apply pipe compound conservatively to male connecting fittings only.

NOTICE:

Do not overtighten when using PTFE impregnated pipe compound

and PTFE tape on pipe threads. Doing so may damage the

valve body.

2.

Check connections for leaks.

Install sweat connection

CAUTION:

• Heat associated with the use of silver solder may damage

valve components and void the product warranty. Do not use

silver solder.

• Excessive use of solder or flux may result in damage to the

internal valve components. Do not use excessive solder or

flux.

1.

Clean tube ends and valve connections thoroughly with a fine grade

emery cloth or fine grit sandpaper.

2.

Adjust the valve to the full open position.

3.

Wrap the valve in a cool wet rag.

4.

Direct the flame being careful to avoid subjecting the valve to

excessive heat.

5.

Allow the valve to cool before touching or operating.

6.

Check the soldered connection for leaks.

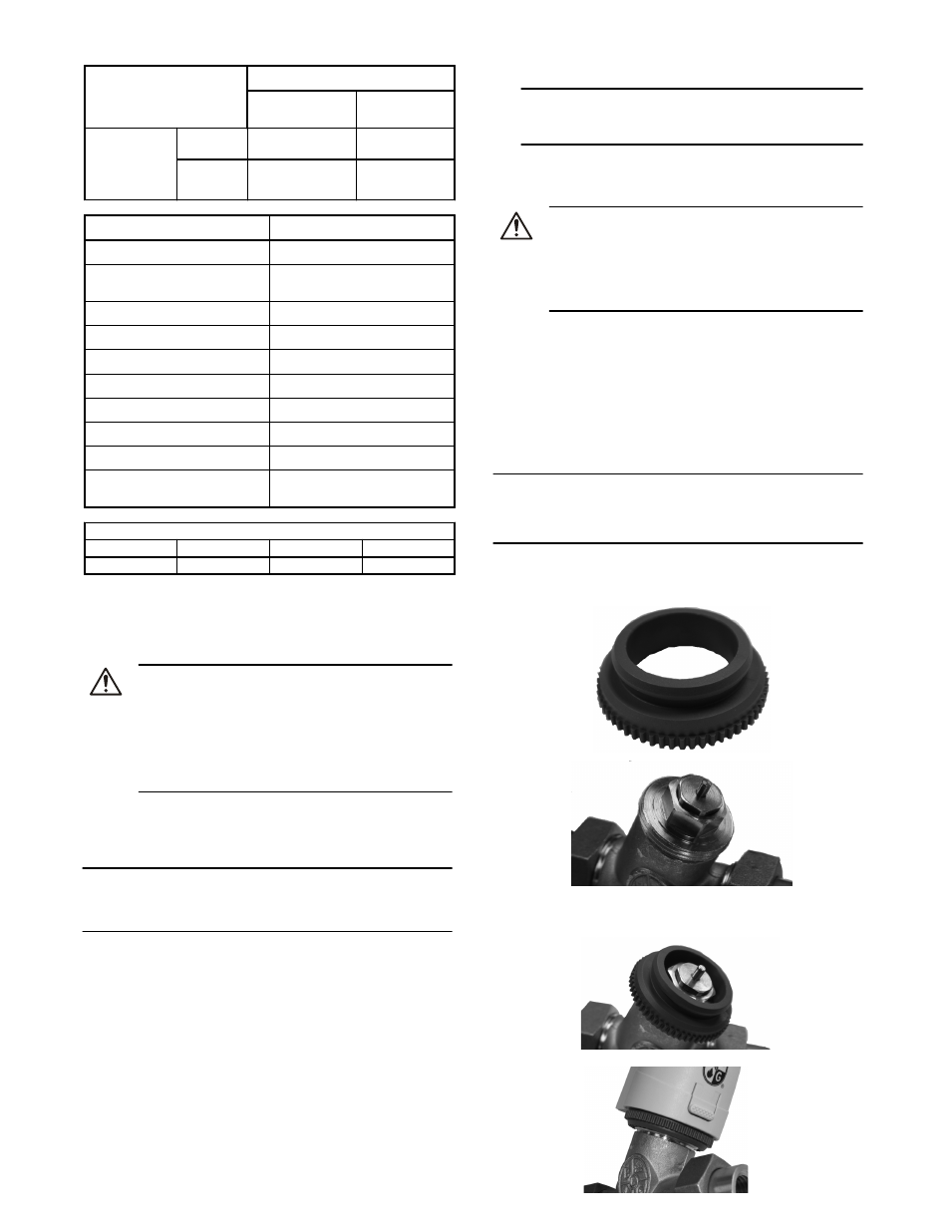

Install the actuator

NOTICE:

To install an actuator on a valve already in line, close the shutoff valves

(upstream first, then downstream) in the piping or turn off the pump. This

procedure allows the differential pressure in the valve to drop.

1.

Make sure that the union connections between the valve and piping

are securely fastened.

2.

Thread the actuator adapter onto the valve body.

3.

Press the actuator onto the valve and adapter until it snaps into place.

When assembled, the actuator can be rotated 360º to aid in positioning

of the terminal wires.

Operational limits

Valve

Maximum Limitations

Temperature ºF (ºC) Max. working pres-

sure PSI (kPa)

Snap Zone

NPT

32ºF (0ºC) to 212ºF

(100ºC) — Fluid

32ºF (0ºC) to 122ºF

(50ºC) — Ambient

240 PSI (1655 kPa)

Sweat

125 PSI (861 kPa)

1

Parameter

Value

Operation

Normally closed

Voltage

24 V AC/DC +20% / 10%, 0–60

Hz

Maximum inrush current

250 mA during 2 min. max.

Operating Current

75 mA

Operating Power

1.8 W

Closing and opening times

Approximately 3 minutes

Actuator stroke

4 mm

Switching point

Approximately 2 mm

Enclosure rating

IP 54

Maximum differential shutoff pres-

sure

60 PSI

Performance Characteristics

Valve size

1/2”

3/4”

1”

Cv

1.8

2.8

2.8

1

Solder type limits for ASTM Std. B16.18 for 95–5 Tin-Antimony Solder