L o a d, Boiler, Piping – Bell & Gossett P86272B VS Variable Speed Pump Control User Manual

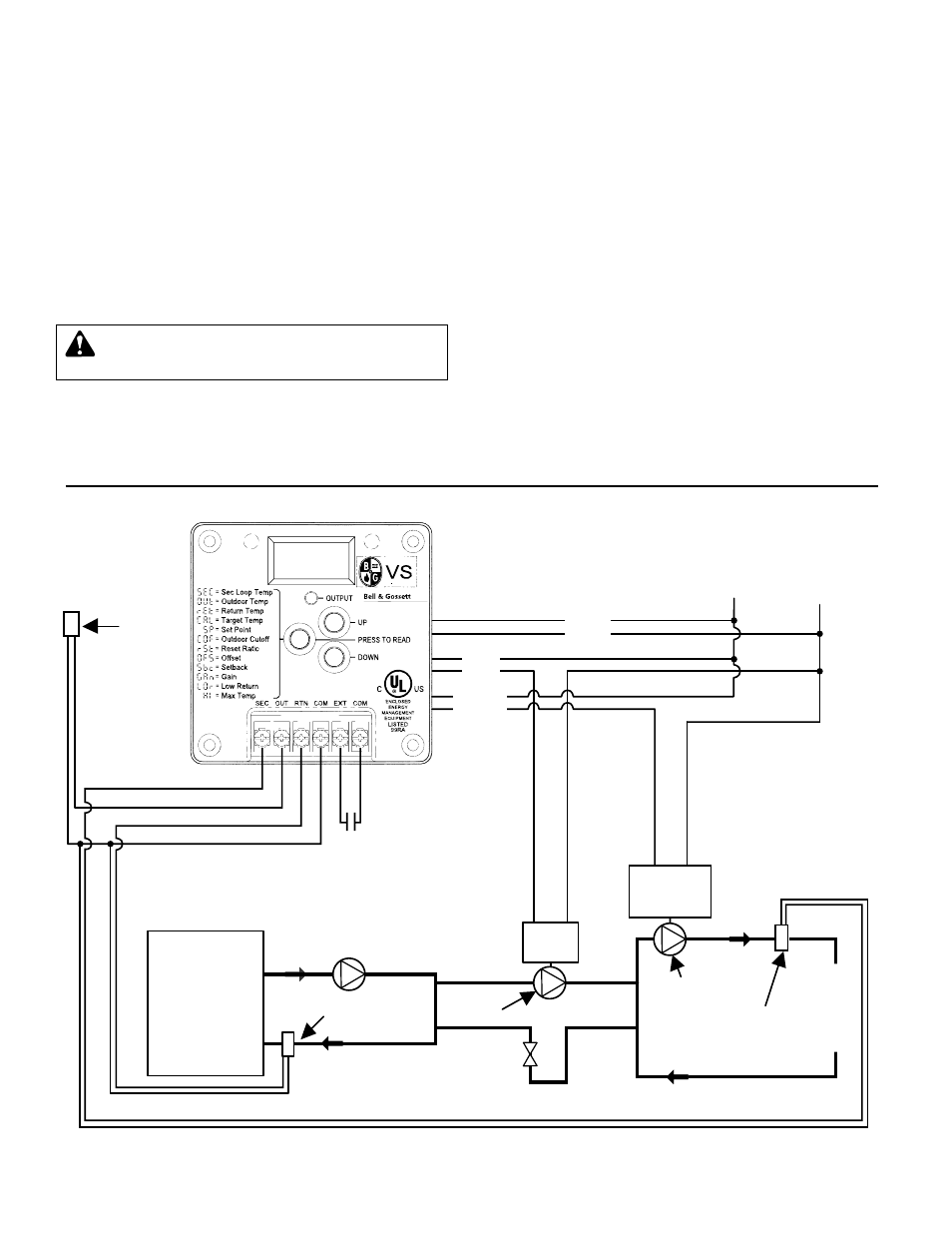

Page 4: Vs wiring diagram (fig. 3)

PIPING

PIPING OVERVIEW

• The Primary loop may have multiple injection loops or other

takeoffs. However, the piping for each injection system

must meet the requirements described below.

• The Injection piping can be installed in either a horizontal or

a vertical configuration.

• The pipe diameters of the Primary and Secondary loops

may differ.

• The Injection Piping diameter must be at least one pipe size

smaller than the smaller of the Primary and Secondary loop

piping. For example, if the Primary loop diameter is 1

1

/

4

"

and the Secondary loop diameter is 1", then the diameter of

the Injection piping must be

3

/

4

" or smaller.

• The Injection pump motor must be a fractional B&G NRF,

NBF or SSF permanent split capacitor type pump. (Refer to

operational limits on Page 2 for pump information.) The

Injection pump will control the amount of water pumped

from the Primary loop into the Secondary loop.

• A balancing valve should be installed on the injection return

piping. This helps to balance the system.

• The distance between the injection tees should be as short

as possible. The rule of thumb distance between the tees is

3 times the pipe diameter. For instance, if the pipe diameter

is 1" then the length of straight pipe between the two

injection tees should be 3".

HORIZONTAL PIPING CONFIGURATION

• The Injection piping can be installed horizontally as shown

in Fig. 2.

• The Injection supply piping should run horizontally from the

Primary to the Secondary loop.

• On the Injection piping it is necessary to install a heat trap

to prevent heat from the Primary loop entering the Secon-

dary loop when the Injection pump is not running.

• The injection piping must drop down vertically at least 18"

and then rise back up vertically at least 18".

VERTICAL PIPING CONFIGURATION

• The Injection piping can be installed vertically.

• The Primary loop must be at least 18" vertically above the

Secondary loop.

4

CAUTION: The Injection pump and pipe sizing

should be performed by a qualified engineer or

contractor.

Secondary

Loop Sensor

Secondary

Loop Pump

Outdoor

Sensor

BLUE

RED

BLACK

120 VAC

LINE

NEU

Setback or

Remote Enable

L

O

A

D

Pump

Starter /

Motor

••

Pump

Motor

•

Injection

Pump

Boiler Return

Sensor

Boiler

•

•

Injection pump must be connected directly to 120VAC motor N.O. pump starter.

••

Secondary pump starter/motor can be 115V or 230V.

VS WIRING DIAGRAM (Fig. 3)

NOTE: Injection Pump and the VS Control MUST be

wired to the same power circuit. The secondary loop

pump can be wired to a different circuit if required.