Xylem IM158 R04 Model SMVT User Manual

Page 17

SMVT Installation, Operation and Maintenance Manual

15

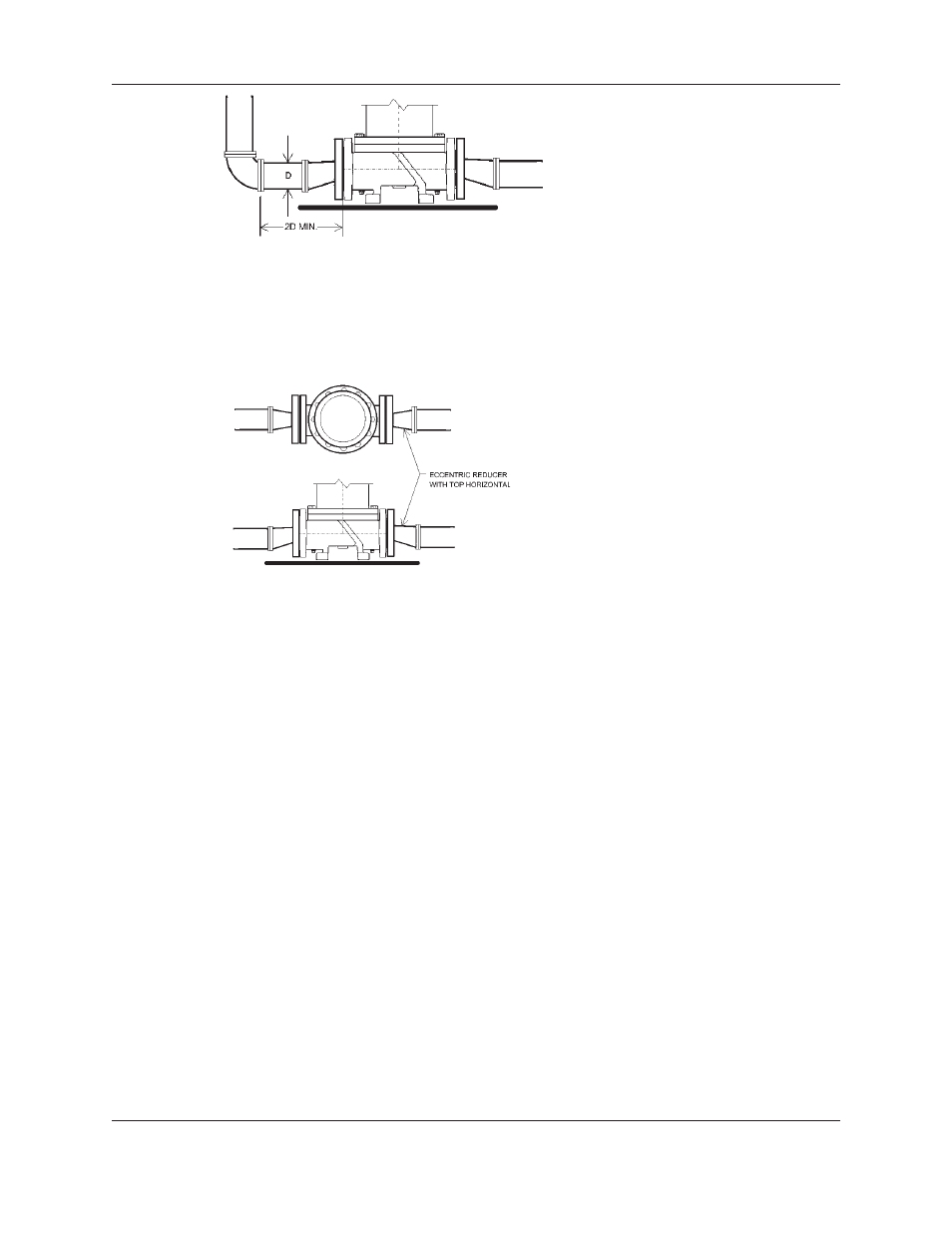

Figure 8: Piping Elbows

2. Use suction pipe that is one or two sizes larger than the pump suction with a reducer at the

suction. Suction piping should never be smaller diameter than the pump suction.

3. Reducers should be eccentric at the pump suction with sloping side down and horizontal

side at the top (Reference Figure 9).

Figure 9: Eccentric Reducer

4. Suction strainers, when used, must have a net “free area” of at least three times the suction

pipe area.

5. Separate suction lines are recommended when more than one pump is operating from the

same source or supply.

Suction Lift Conditions

If pump is to be installed above the liquid source, the following MUST be provided:

1. No part of the suction piping can be above the pump suction (to avoid air pockets).

2. Suction piping must slope upwards to the pump on any horizontal pipe sections.

3. All joints MUST be airtight.

4. A means of maintaining prime during intermittent duty, such as a foot valve, must be

provided.

5. The suction strainer or suction bell MUST be at least three times the diameter of the

suction.

6. Ensure that the size and minimum submergence over the suction inlet is sufficient to prevent

air from entering the pump through a suction vortex. See typical intake piping arrangements

in Figures 10-13.

Installation (continued)