Xylem IM158 R04 Model SMVT User Manual

Page 16

14

SMVT Installation, Operation and Maintenance Manual

3. DO NOT connect piping to pump until pump and/or driver are securely fastened to a

supporting structure.

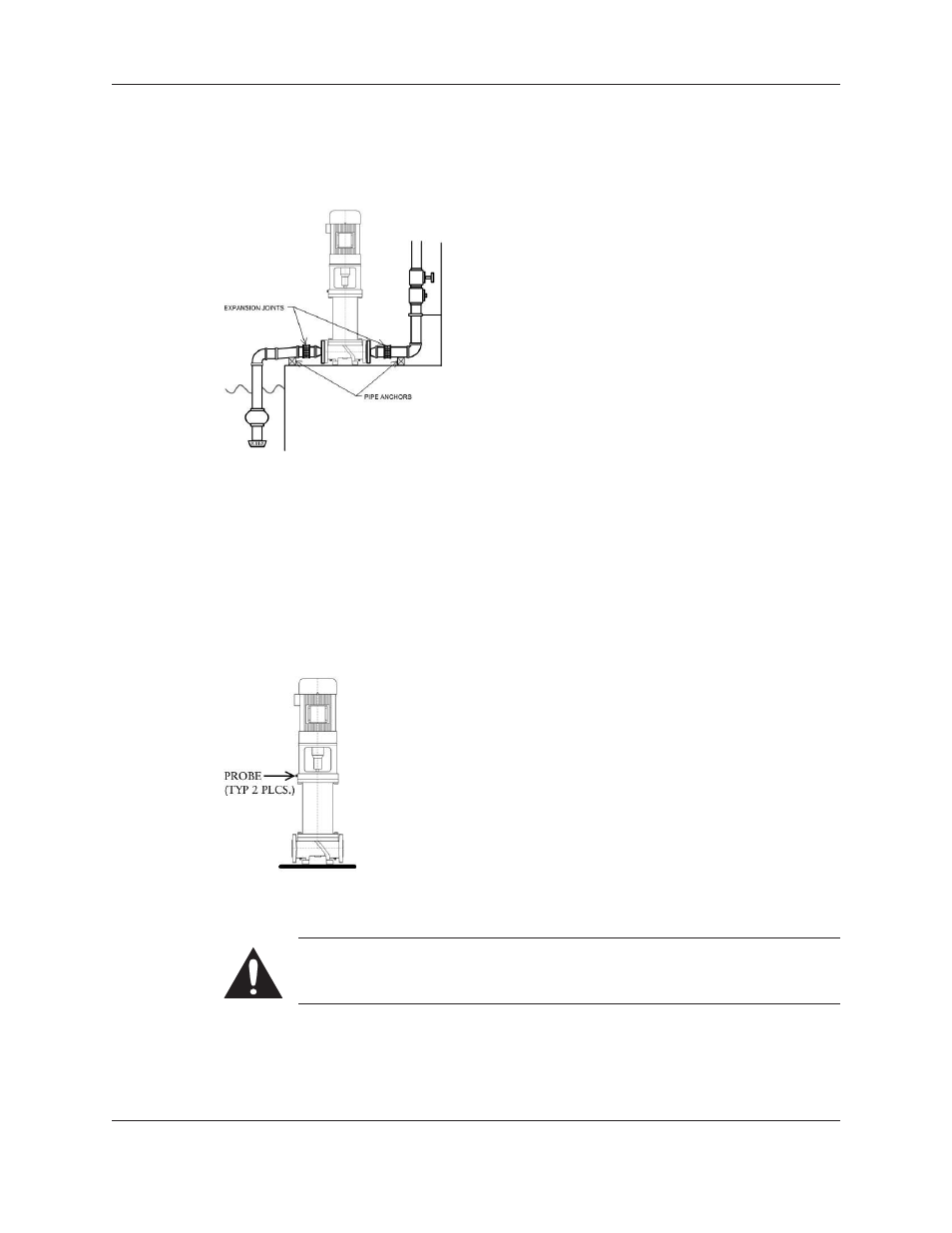

4. When pumping liquids at elevated temperatures, it is recommended that expansion loops or

joints be used in the suction and discharge piping. Refer to Figure 6 for correct placement

to avoid pump strain or misalignment due to linear expansion of piping.

Figure 6: Correct Placement of Expansion Joint

5. The piping should be arranged to permit pump isolation on both the suction and discharge

sides so that the pump can be drained during maintenance and repair.

6. Carefully clean all pipe parts, valves and fittings and pump branches prior to assembly.

7. All pipe joints MUST be airtight.

8. Proper placement of any temperature probes should be at the top end of the pump

unit casing in one of the provided ports. Ports will come from factory plugged. Proper

temperature probe location is shown in Figure 7.

Figure 7: Correct Placement of Temperature Probes

Suction Piping

Warning: NPSH available must always exceed NPSH required by the pump. For

suction lifts over 10 feet (3 meters) and liquid temperatures over 120°F (49°C),

consult the performance curve for your pump to determine NPSH required.

Properly installed suction piping is a necessity for trouble-free pump operation. Suction

piping should be flushed BEFORE connection to the pump.

1. Use of elbows close to pump suction should be avoided. There should be a minimum of two

pipe diameters of straight pipe between elbow and suction inlet (Reference Figure 8). All

elbows should be long-radius.

Installation (continued)