Xylem 19-001-350R2 PACE Integrated Pump Controller Human Machine Interface (HMI) for the Silent Storm VFD Pumping System – Technician Guide User Manual

Page 12

12

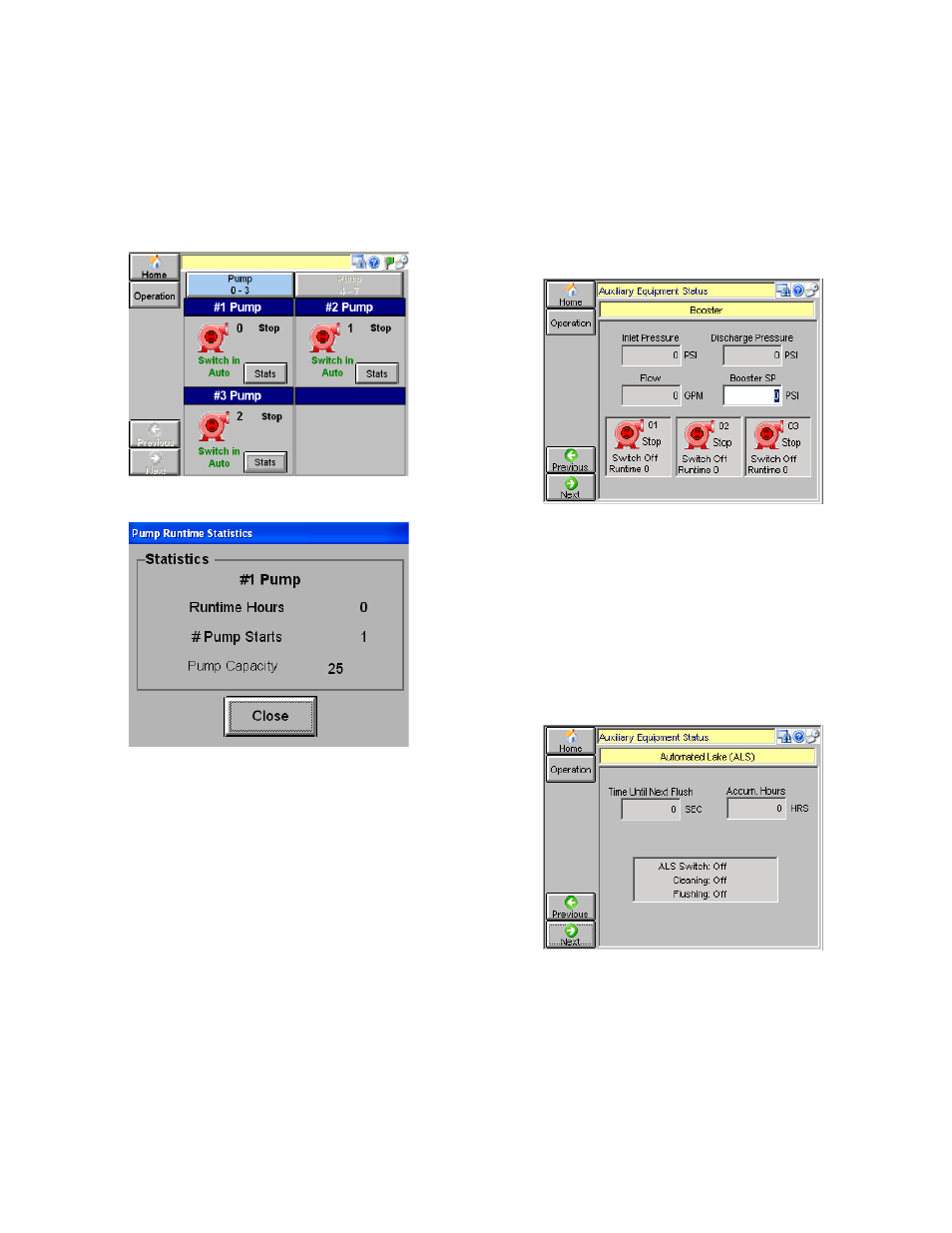

Red, no animation: Stopped pump

Green, rotating center: Running pump

Yellow, flashing center: Fault condition

Individual pump stats (runtime hours, number of

starts, and pump capacity in GPM) can be viewed

by tapping [Stats] for each pump.

Figure 18: Animated Pump Status

Figure 19: Individual Pump Stats

AUXILIARY EQUIPMENT STATUS

Tap [Aux. Equipment Status] from the Operation

menu.

By tapping [Previous] or [Next], you can navigate

the status screens for each device that has been

set up.

NOTE: The screens described below will only be

displayed if they are applicable to the current

system.

Booster Pumps:

Booster Pumps are typically custom features and

the interface depends greatly on the specific site.

However some basic functionality is provided.

Booster pumps typically require an auxiliary PLC.

Up to three booster pumps may be monitored

simultaneously. All fields are read-only with the

exception of ‘Booster SP’. This pressure (PSI) value

remains same for all installed boosters, and is

generally higher than user defined SP.

Red, no animation: Stopped

Green, rotating center: Running

Yellow, flashing center: Fault condition

Tap [Next] to move to the next status screen.

Figure 20: Booster Monitoring Screen

Automated Lake (ALS) Monitoring Screen

This screen is used to monitor the Automated Lake

Screen. ‘Accum Hours’ is the total accumulated

time ALS has been running for. ‘ALS Switch’

denotes the position of ALS switch on the

enclosure. ‘Cleaning’ and ‘Flushing’ denote

if the respective cycles are on or off.

Tap [Next] to move to the next status screen.

Figure 21: ALS Monitoring Screen

Lake Level Controls Monitoring Screen

A maximum of eight lake level controls can be

monitored/configured on this screen. Supervisor

access or higher is required to configure, but guest

level access can view the settings and status

information.