Appendix “a” engineering data, Casing data, Stuff box data – Xylem 8100 Series Centrifugal Pumps AC2515 REV.C User Manual

Page 54: Impeller design data, Shaft and bearing data

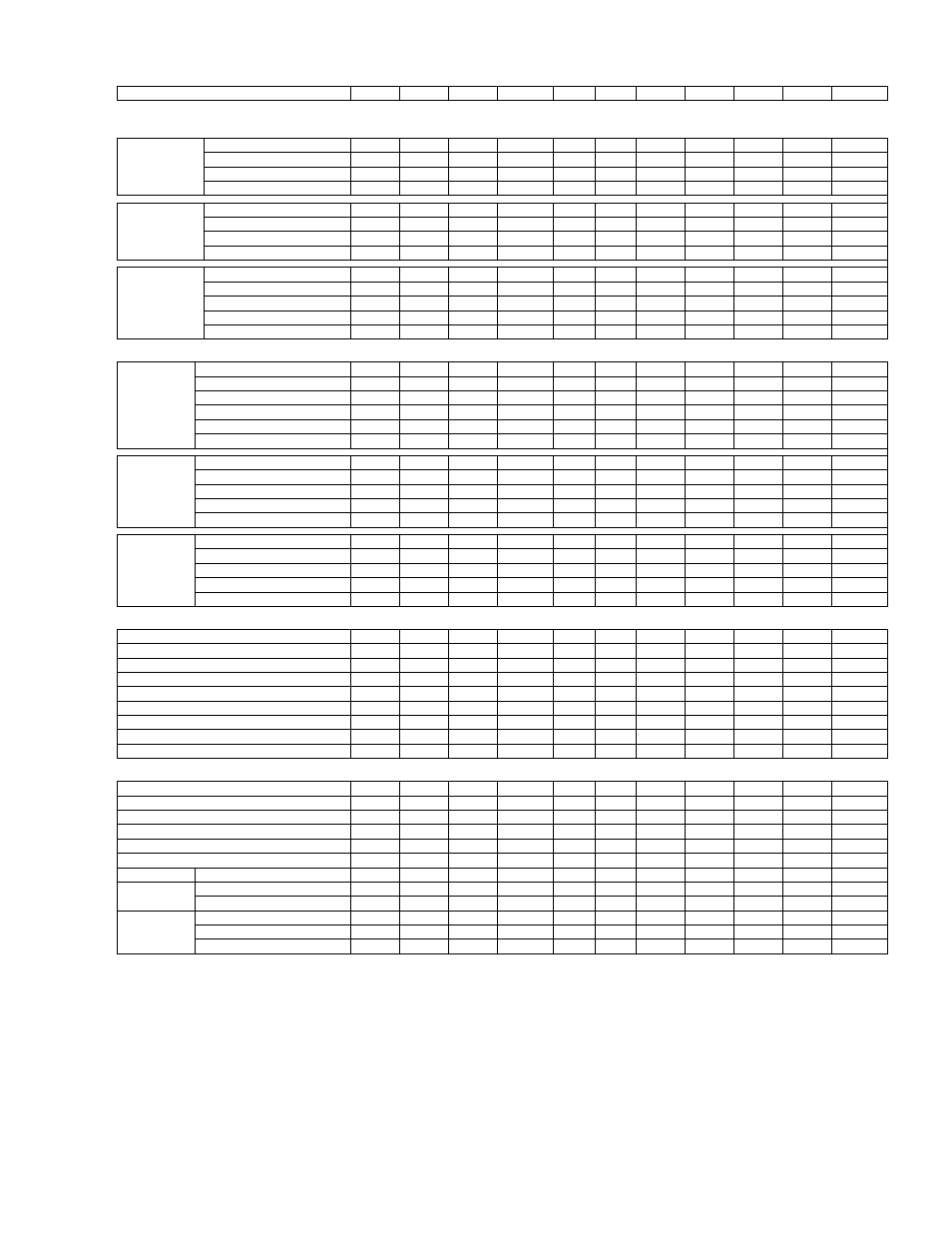

APPENDIX “A” ENGINEERING DATA

Pump Size

6x4x12L 6x4x12XL 6x4x14S

6x4x14L

6x6x9

8x6x9

8x6x10

8x6x12S

8x6x12M

8x6x12L

8x6x12XL

K

CASING

DATA

(All Dimensions in Inches)

125# FF Std

Max. Suction Pressure

75

75

75

75

75

75

75

75

75

75

75

f ASA Flanges

Max. Working Pressure

175

175

175

175

175

175

175

175

175

175

175

h NOMINAL 175 PSI Max. Hydrostatic Test Pressure

262

262

262

262

262

262

262

262

262

262

262

Working Press.

Casing material

Cast I

Cast I

Cast I

Cast I

Cast I

Cast I

Cast I

Cast I

Cast I

Cast I

Cast I

g 250# FF

Max. Suction Pressure

200

200

200

200

200

200

200

200

200

200

200

c NOMINAL 280 PSI Max. Working Pressure

280

280

280

280

280

280

280

280

280

280

280

h Working Press.

Max. Hydrostatic Test Pressure

420

420

420

420

420

420

420

420

420

420

420

Casing material

Ductile I

Ductile I

Ductile I

Ductile I

Ductile I Ductile I Ductile I

Ductile I

Ductile I

Ductile I

Ductile I

g 250# FF

Max. Suction Pressure

300

300

300

300

300

300

300

300

300

300

300

d NOMINAL 400 PSI Max. Working Pressure

400

400

400

400

400

400

400

400

400

400

400

e Working Press.

Max. Hydrostatic Test Pressure

600

600

600

600

600

600

600

600

600

600

600

h

Casing material

Ductile I

Ductile I

Ductile I

Ductile I

Ductile I Ductile I Ductile I

Ductile I

Ductile I

Ductile I

Ductile I

Casing

Wall

Thickness

.375 .375 .50 .50 .50

.50 .50 .50 .44 .44 .44

STUFF BOX DATA

(All Dimensions in Inches)

Packing

Bore

2.625 2.625 2.625 2.625 2.625

2.625 3.25 2.625 3.25 2.625 2.625

Dimensions

Depth

2.56 2.56 2.56 2.56 2.56

2.56 3.50 2.56 3.50 2.56 2.56

Sleeve

O.D.

1.875 1.875 1.875 1.875 1.875

1.875 2.25 1.875 2.25 1.875 1.875

Packing Size/No. Rings W/O S. Cage

6.375

6.375

6.375

6.375

6.375

6.375

6.50

6.375

6.50

6.375

6.375

Packing Size/No. Rings W/ S. Cage

5.375

5.375

5.375

5.375

5.375

5.375

5.50

5.375

5.50

5.375

5.375

Seal

Cage

Width

.50 .50 .50 .50 .50

.50 .75 .50 .75 .50 .50

Mech.

Seal Bore

2.25 2.25 2.25 2.25

2.25

2.25 2.25

On Shaft

Depth

2.62

2.62

2.62

2.62

2.62

2.62

2.62

i Dimensions

Mech. Seal Size (Type 21 or 1)

1.38

1.38

1.38

1.38

1.38

1.38

1.38

Balanced Mech.

Major Dia.-->

1.50

1.50

1.50

1.50

1.50

1.50

1.50

l

{

Seal Size (Type 1B) Minor Dia.-->

1.38

1.38

1.38

1.38

1.38

1.38

1.38

Mech.

Seal Bore

3.00 3.00 3.00 3.00

3.00 3.38 3.00 3.00

On

Sleeves Depth

2.56 2.56 2.62 2.62

2.62 2.88 2.62 2.62

Dimensions

Mech. Seal Size (Type 21 or 1)

1.875

1.875

1.875

1.875

1.875

2.25

1.875

1.875

Balanced

Mech.

Major

Dia.-->

2.00 2.00 2.00 2.00

2.00 2.38 2.00 2.00

l

{

Seal Size (Type 1B) Minor Dia.-->

1.88

1.88

1.88

1.88

1.88

2.25

1.88

1.88

IMPELLER DESIGN DATA

(All Dimensions in Inches)

No. of Vanes

6

7

6

6

6

6

6

5

5

7

7

Inlet Area (Sq. Inches)

19.1

28.4

19.1

22.9

5.9

12.0

15.2

27.0

20.4

38.9

40.6

Inlet

Velocity

per

100

GPM

(Ft/Sec)

1.7

1.1 1.7 1.4 5.4

2.7 2.1 1.2 1.6 .83 .79

Maximum

Diameter

12.8 14.0 13.8 13.8 9.8 9.8 10.0 12.8 12.8 12.8 13.7

Minimum

Diameter

6.0

7.0 6.5 7.0 6.5

6.5 7.6 7.0 6.5 7.0 7.0

Maximum

Sphere

.60

.37 .47 .68 .48

.64 .75 .72 .87 1.0 1.0

WR

^2

for

Maximum

Diameter

(Lbs-Ft^2)

3.1

3.5 7.5 8.0 2.5

2.6 3.1 3.6 3.7 3.8 8.5

j Wear Ring Clearance – Diam. 175# & 280# W.P.

.010-.012 .010-.012 .010-.012 .010-.012 .010-.012 .010-.012 .010-.012 .010-.012 .010-.012 .010-.012 .010-.012

ej Wear Ring Clearance – Diam. 400# W.P.

.020-.024 .020-.024 .020-.024 .020-.024 .020-.024 .020-.024 .020-.024 .020-.024 .020-.024 .020-.024 .020-.024

SHAFT AND BEARING DATA

(All Dimensions in Inches)

Under

Sleeve

1.499 1.499 1.499 1.499 1.499

1.499 1.874 1.499 1.874 1.499 1.499

Under Mech. Seal on Shaft Type 21 or Type 1

1.375

1.375

1.375

1.375

1.375

1.375

1.375

Under Mech. Seal on Shaft Type 1B

1.500

1.500

1.500

1.500

1.500

1.500

1.500

At

Coupling

1.125 1.125 1.125 1.125 1.125

1.125 1.375 1.125 1.375 1.125 1.125

Thru Impeller with Packing – Mech. Seal on Sleeve

1.686

1.686

1.686

1.686

1.687

1.687

1.937

1.686

1.937

1.686

1.686

k Thru Impeller with Mech. Seal on Shaft

1.689

1.689

1.689

1.689

1.689

1.689

1.689

Shaft Span

Bearing to Bearing Centerline

22.90

22.90

22.90

22.90

22.00

25.25

25.25

22.90

25.25

22.90

22.90

Inboard 6206

6206

6206

6206

6206

6206

6208

6206

6208

6206

6206

Ball Bearings

Outboard 5206

5206

5206

5206

5206

5206

5307

5206

5307

5206

5206

Packing

F20-C4 F20-C4 F20-C4 F20-C4 F20-G4

F20-H4

F20-I4 F20-C4 F20-B4 F20-C4 F20-C4

Mech. Seal on Shaft

F20-C5

F20-C5

F20-C5

F20-C5

F20-C5

F20-C5

F20-C5

Frame

Designation

Mech. Seal on Shaft Sleeve

F20-C6

F20-C6

F20-C6

F20-C6

F20-C6

F20-B6

F20-C6

F20-C6

c With 250# FF flanges and 280# PSIG working pressure refer to pump as

M3x2x11S.

d With 250# FF flanges and 400# PSIG working pressure refer to pump as

H3x2x11S.

e For pumps with 400 PSI working pressure, wear ring clearances are doubled.

Derate pump efficiencies by 2 percentage points.

f Flange dimensions are in accordance with ANSI A21.10, AWWA C110 & ANSI

B16.1 class 125.

g Flange dimensions are in accordance with ANSI B16.1 class 250 except flanges

are flat faced, i.e. FF.

h The hydrostatic test will be accordance with the latest edition of the Hydraulic

Institute Standards, test will maintained for a minimum of 5 minutes.

i Type 1 and 21 seals have the same working lengths.

j For bronze impellers and casing rings. For diametral clearances for other

materials, consult factory.

l

Impeller is a light press fit on shaft, do not use construction with stainless steel

impellers.

K

Not available in mechanical seal on shaft arrangement.

54