Stuffing box lubrication – Xylem 8100 Series Centrifugal Pumps AC2515 REV.C User Manual

Page 17

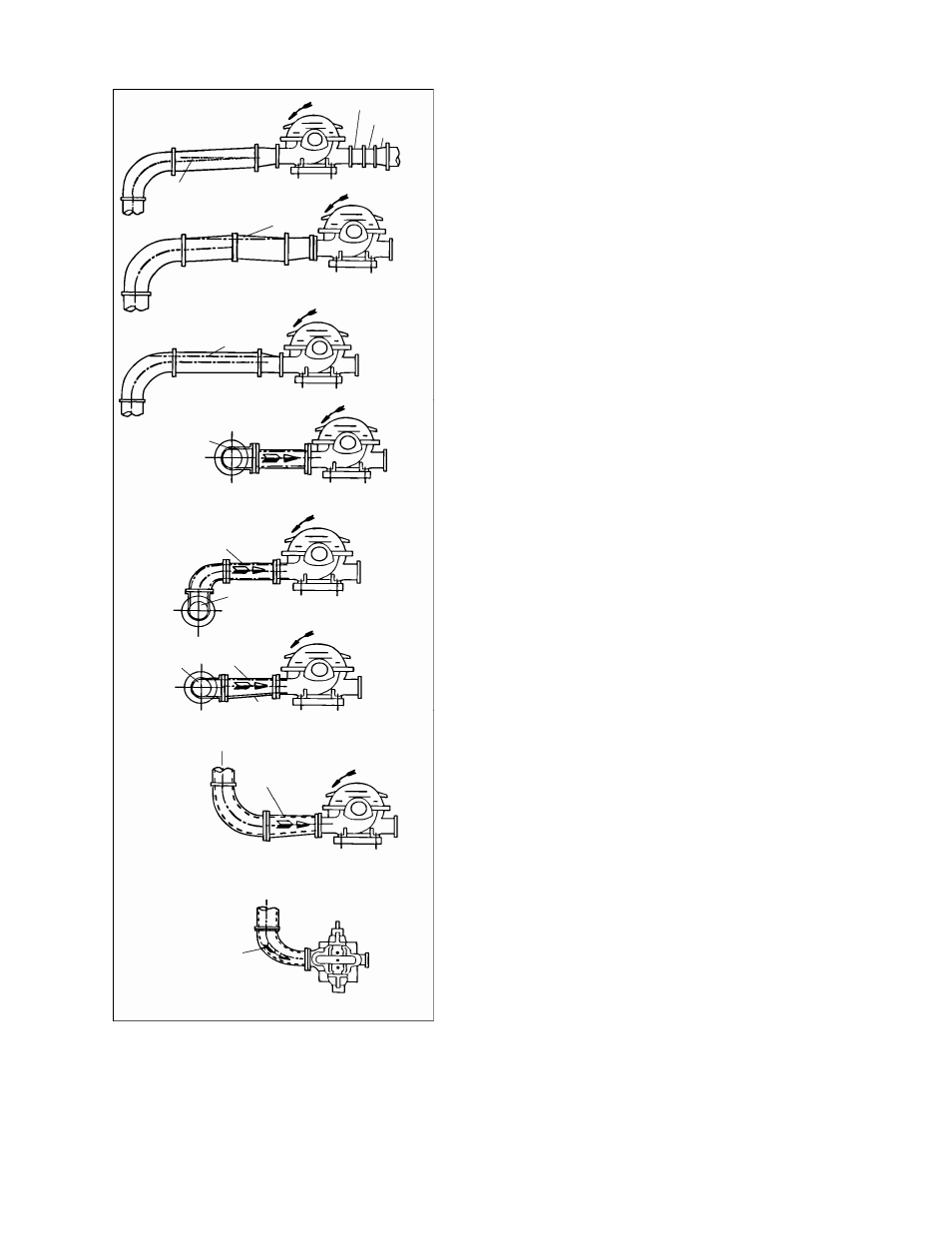

FIGURE 13 – SUCTION PIPING

ARRANGMENTS

Discharge Piping

CHECK VALVE

If the discharge piping is short, the pipe

diameter can be the same as the discharge

opening. If the piping is long, the pipe

diameter should be one or two sizes larger

than the discharge opening. On long

horizontal runs, it is desirable to maintain an

even a grade as possible. Avoid high spots,

such as loops, which will collect air and

throttle the system or lead to erratic pumping.

GATE VALVE

SUCTION PIPE INSTALLED

WITH A GRADUAL RISE TO PUMP

INCREASER

LEVEL

CENTER LINE

OF PIPE

CORRECT

AIR POCKET

INCORRECT

A slow closing check valve and an isolating

gate valve should be installed in the

discharge line. The check valve (triple duty

valve), placed between pump and gate valve,

protects the pump from excessive back

pressure, and prevents liquid from running

back through the pump in case of power

failure. The gate valve is used in priming and

starting, and when shutting the pump down.

AIR POCKET

INCORRECT

AIR POCKET

Pressure Gauges

Properly sized pressure gauges should be

installed in both the suction and discharge

nozzles in the gauge taps provided. The

gauges will enable the operator to easily

observe the operation of the pump, and also

determine if the pump is operating in

conformance with the performance curve. If

cavitation, vapor binding, or other unstable

operation should occur, widely fluctuating

discharge pressure will be noted.

INCORRECT

GRADUAL RISE

TO PUMP

NO AIR

POCKETS

CORRECT

GRADUAL RISE

TO PUMP

NO AIR

POCKETS

STUFFING BOX LUBRICATION

ECCENTRIC

REDUCER

Contaminants in the pumped liquid must not enter

the stuffing box. These contaminants may cause

severe abrasion or corrosion of the shaft, or shaft

sleeve, and rapid packing or mechanical seal

deterioration; they can even plug the stuffing box

flushing and lubrication system. The stuffing box

must be supplied at all times with a source of

clean, clear liquid to flush and lubricate the

packing or seal. It is important to establish the

optimum flushing pressure that will keep

contaminants from the stuffing box cavity. If this

pressure is too low, fluid being pumped may enter

the stuffing box. If the pressure is too high,

excessive packing or seal wear may result; and

extreme heat may develop in the shaft causing

higher bearing temperatures. The most desirable

condition, therefore, is to use a seal water

pressure 15-20 psig above the maximum stuffing

box pressure.

CORRECT

DISTANCE PLUS

ECCENTRIC REDUCER

STRAIGNTENS FLOW

CORRECT

PATH OF WATER

INCORRECT

If the pump system pressure conditions vary

during the day, packing adjustment becomes

17