Xylem 8100 Series Centrifugal Pumps AC2515 REV.C User Manual

Page 40

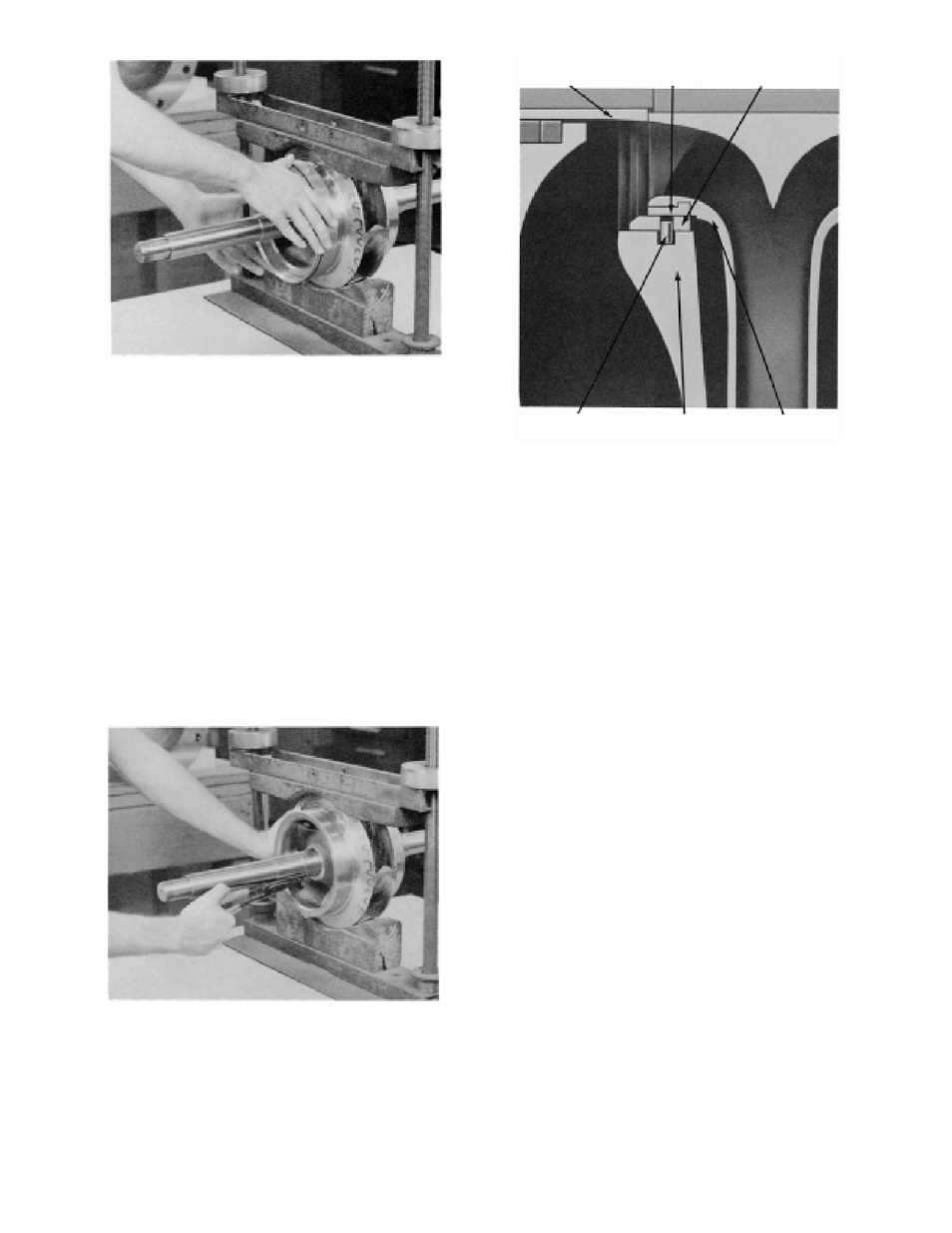

FIGURE 31 – REMOVING CASING RINGS

FROM IMPELLER

10. Remove mechanical seal head (3-402-0)

from the pump shaft.

11. Remove two casing rings (3-003-9) from

the impeller (4-002-0) and remove O-rings

(3-914-2) from each casing ring (See

Figure 31).

12. Remove the impeller retaining ring (3-915-

1) with a retaining ring pliers (Figure 32).

Heat the impeller hub on both ends to

350°F maximum, and pull or push the

impeller from the shaft. (Instead of heating

impeller, you may press impeller off of

shaft, if a press is available.

NOTE: Press away from coupling end.

FIGURE 32 – REMOVING IMPELLER FROM

RETAINING RINGS

NOTE: For impellers with replaceable rings –

remove the rings (0-004-0), if necessary, by

cutting with a cold chisel. (See Figure 33)

(3-009-9)

SLEEVE

(0-004-0)

IMPELLER RING

(3-003-9)

CASING RING

CASING

(2-001-0)

LOCKING PIN

(3-943-9)

IMPELLER

(4-002-0)

FIGURE 33 –IMPELLER WITH WEAR RINGS

13. Remove the impeller key (3-911-1) from

the shaft.

ASSEMBLY (PUMP WITH MECHANICAL

SEALS ON SHAFT)

All bearings, O-rings, lip seals, mechanical seals,

gaskets, impeller rings, and casing rings should be

replaced with new parts during assembly. All

reusable parts should be cleaned of all foreign

matter before reassembling. The main casing joint

gasket can be made using the upper or lower half

as a template. Lay the gasket material on the

casing joint. Trim the gasket by lightly tapping with

a ball peen hammer so that it is flush with the

inside edges of the casing.

NOTE: Precut casing gaskets (2-123-5 and -6)

can be ordered to minimize the amount of

trimming.

1. Assemble the impeller key (3-911-1) in the

shaft key slot.

2. Check the impeller (4-002-0) and casing

to determine the correct relationship (See

Figure 16). Heat the impeller evenly to

300°F maximum to expand the bore.

(Impeller may be pressed onto the shaft

instead of heating if a suitable press is

available, see Figure 34.)

40