Xylem 8100 Series Centrifugal Pumps AC2515 REV.C User Manual

Page 36

FIGURE 24 – INSTALLING LIP SEAL

10. Lubricate and roll O-ring (3-914-1) into the

groove in each stuffing box.

11. Slide outboard stuff box on the shaft so

that the shaft end extends through the

packing area, but does not enter the lip

seal. This will permit installation of

deflector (3-136-9).

12. Slide the deflector over the shaft end then

carefully push the shaft end through the lip

seal and slide the stuffing box fully onto

the shaft.

CAUTION:

DO NOT EXCEED 275°F.

13. Heat the ball bearing (3-026-4), using

either dry heat or a 10-15% soluble oil and

water solution.

14. Using gloves, slide the heated bearing

onto the shaft against the shaft shoulder

(See Figure 25).

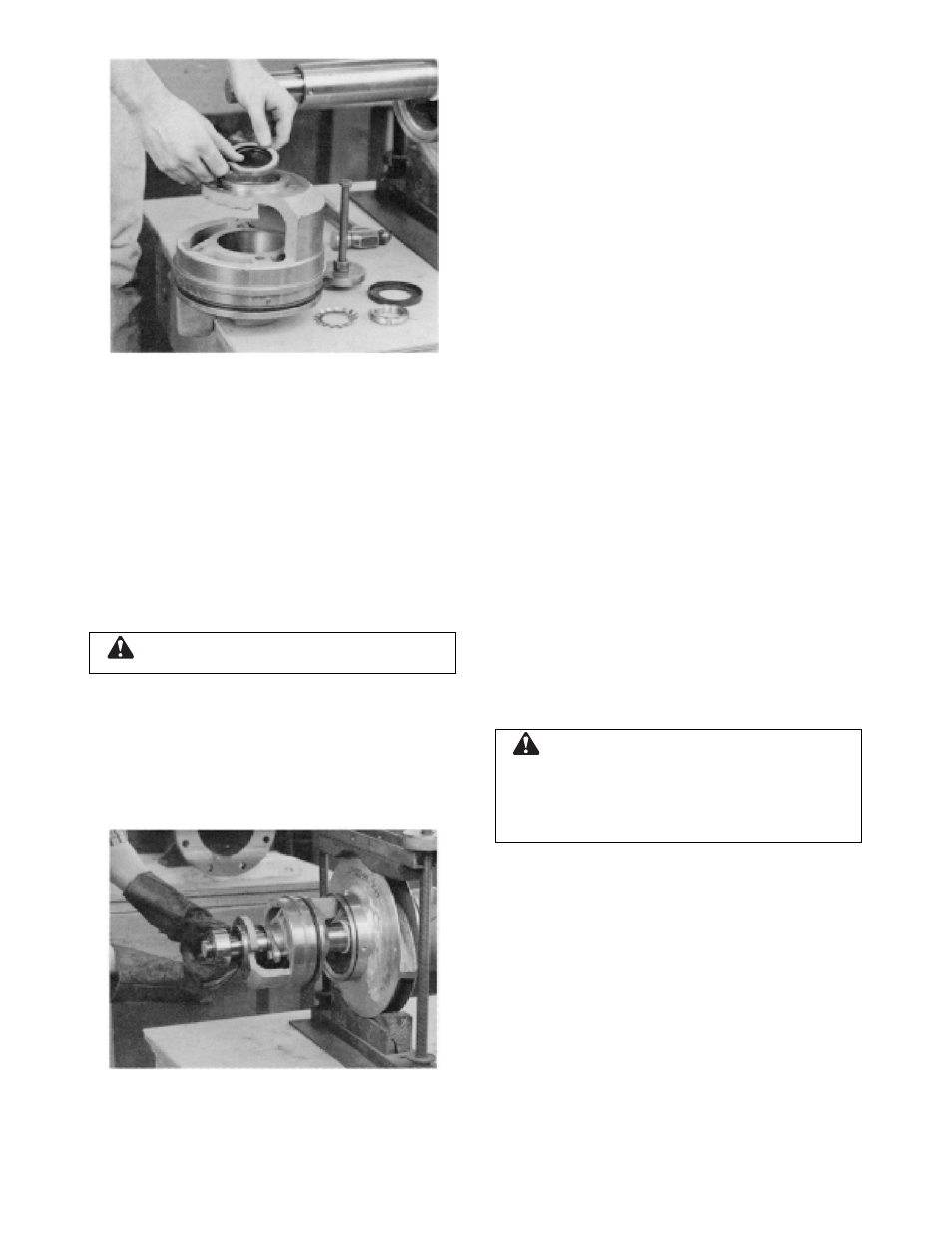

FIGURE 25 – INSTALLING SHAFT BEARING

15. Install lockwasher (3-517-4) and locknut

(3-516-4) on the outboard end of the shaft.

Make certain locknut is secured and then

bend over tabs on lockwasher.

16. Allow the bearing to cool to room

temperature. On grease lubricated

bearings only, coat the exposed sides with

two or three ounces of recommended

grease.

17. On grease lubricated bearings, coat the

inside of the bearing housing (3-025-4)

with grease and slide into place over

bearing. Attaching the bearing housing to

the stuffing box with four cap screws (3-

904-9).

18. Repeat steps 11 through 14, 16 and 17 for

the inboard end.

NOTE: A locknut and lockwasher are not

installed on the inboard end of the shaft.

19. Clean the gasket surfaces of the casing.

Apply Scotch 3M-77 spray adhesive or

equivalent to the lower half of the casing.

20. Within one minute of spraying, set the

untrimmed gaskets (2-123-5 and -6) in

place on the lower half casing, align the

holes in the gaskets with the holes in the

casing and press the gaskets firmly

against the lower half casing face in the

area coated by the adhesive.

21. Trim the gaskets flush with the lower

casing bores, if this has not been done as

yet.

CAUTION:

Machined casing bores must remain sharp

at the casing parting line. Gaskets must be flush

with bore in order to contact O-rings. Leakage can

result around stuff box O-ring if this step is not

properly followed.

22. Set the rotating element in the pump

casing (2-001-0), assuring correct rotation.

Locate both stuffing box tongues in their

respective casing grooves. Locate pins (3-

943-9) in the stuffing box and the casing

wear rings in their respective slots at the

casing parting surface. Correct any O-ring

bulging (See Figure 26).

36