Q-Tech QT802 Square Wave User Manual

Page 6

QT801 and QT802 Square-Wave

24 pin DDIP

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 6 of 10

D

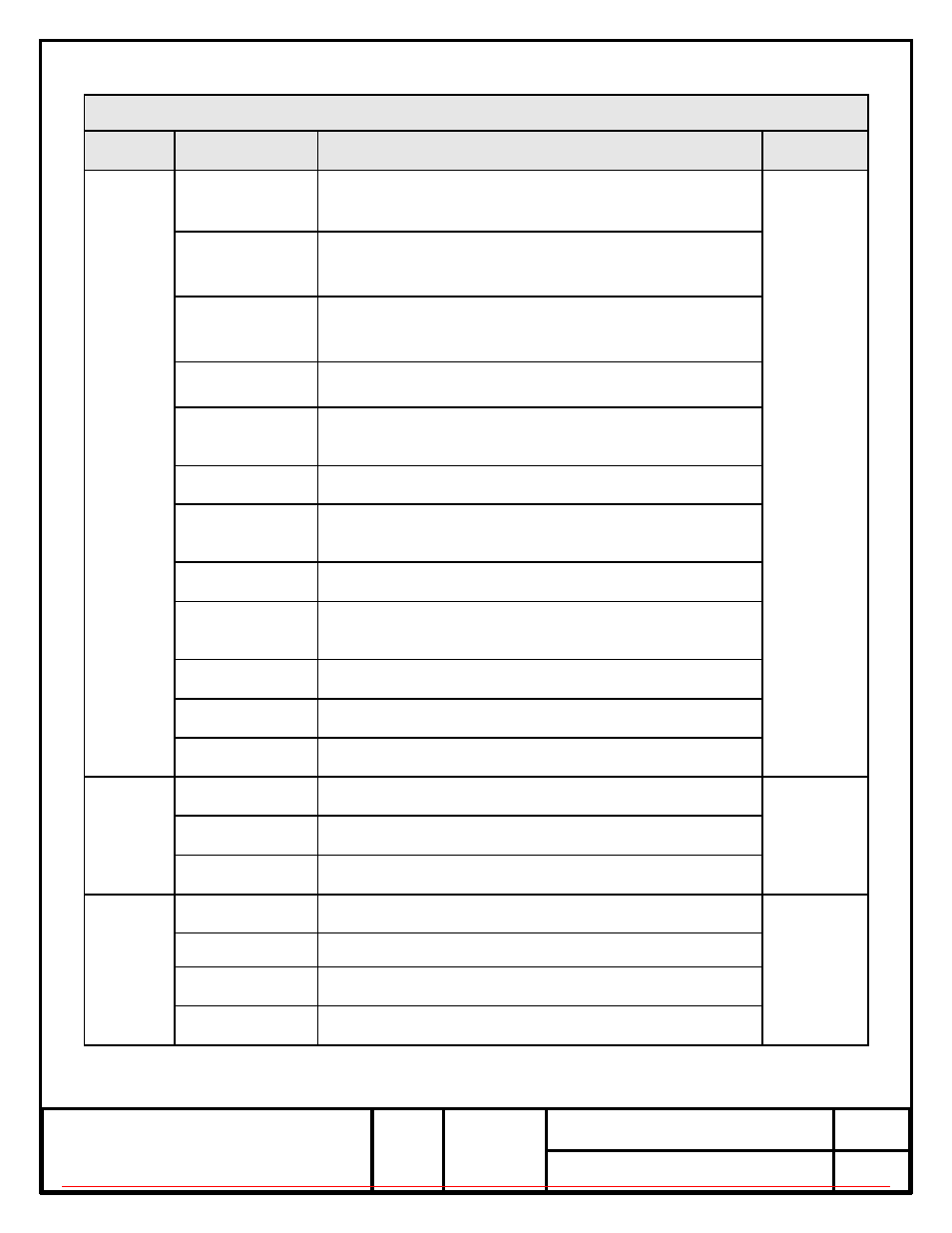

Group C Inspection

SUB-

GROUP

TEST

DESCRIPTION

CONDITION

QTY

Vibration (random)

MI-STD 202 Method 214/ T.C. I-K (46Grms) for 3 minutes in

each plane.

Shock

MI-STD 202 Method 213 T.C. F

(1500g, 0.5ms half-sine pulse) 3 blows each direction of three

axes (18 shocks total)

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical

Specification.

Hermetic Seal

Fine Leak – MIL-STD-883 Method 1014 Condition A1

Gross Leak – MIL-STD-883, Method 1014 Condition C

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical

Specification.

Temperature

Cycling

MI-STD 883, Method 1010, TC B 100 cycles.

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical

Specification

Ambient Pressure

(Non-Operating

2 MI-STD 202 Method 105 T.C. C

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical

Specification

Storage

Temperature

Low Temp.of - 55 (+0, -5) °C

HighTemp.of +150 (+5,-0) °C

Hermetic Seal

Fine Leak – MIL-STD-883 Method 1014 Condition A1

Gross Leak – MIL-STD-883, Method 1014 Condition C

1

Electrical Test

Frequency, Output levels, Input Current @ +25°C & Temp

Extremes listed on the Electrical Specification

4 parts

(0 failures)

Resistance to

Soldering Heat

MI-STD 202 Method 210 T.C. B

Hermetic Seal

Fine Leak – MIL-STD-883, Method 1014 Condition A1

Gross Leak – MIL-STD-883, Method 1014 Condition C

3

Moisture

Resistance

MI-STD 202 Method 106

1 parts

(0 failures)

Terminal Strength

(Lead Integrity)

MI-STD 202 Method 211 T.C. B

Visual Inspection

Hermetic Seal

Fine Leak – MIL-STD-883,Method 1014 Condition A1

Gross Leak – MIL-STD-883, Method 1014 Condition C

4

Resistance To

Solvents

MI-STD 202 Method 215

1 parts

(0 failures)

NOTE: Samples from Subgroup 1 may be divided and used for Subgroups 2, 3, and 4 Inspections.

ITAR-CONTROLLED Q-TECH PROPRIETARY DO NOT COPY OR DISTRIBUTE WITHOUT Q-TECH APPROVAL