Q-Tech QT802 Square Wave User Manual

Page 4

QT801 and QT802 Square-Wave

24 pin DDIP

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 4 of 10

D

3.2.1 Physical Characteristics

3.2.1.1 Dimensions - The TCXO outline dimensions and terminal connections shall be as shown in Figure 1

herein.

3.2.1.2 Weight - The TCXO shall weigh less than or equal to 15 grams.

3.2.1.3 Materials - The TCXO package body and lead finish shall be gold in accordance with MIL-PRF-38534.

3.3

Design and Construction

The design and construction of the crystal oscillator shall be as specified herein. As a minimum, the

oscillators shall meet the design and construction requirements of MIL-PRF-55310, except element

evaluation shall be as specified in 3.3.1

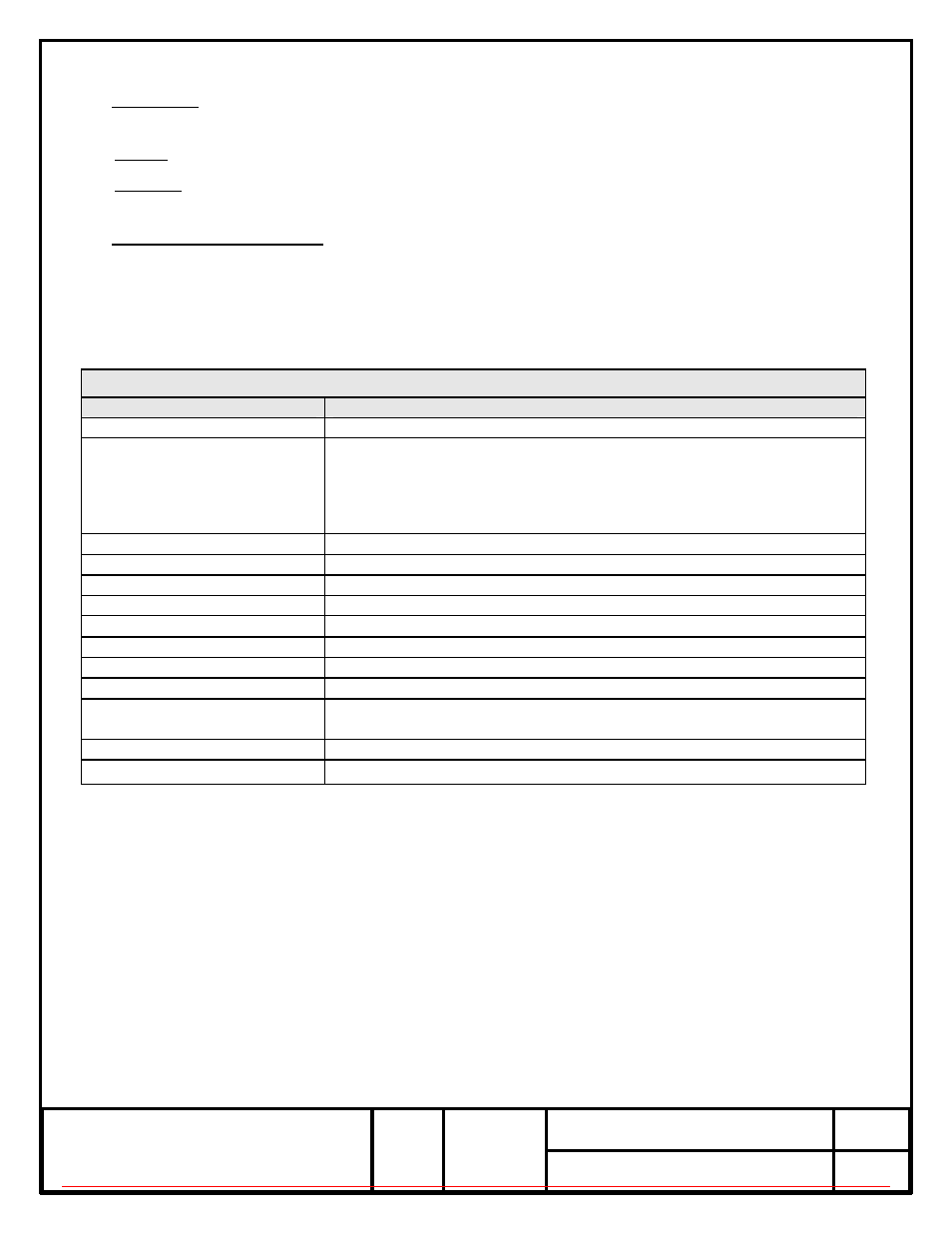

SCREENING FLOW CHART

Operation

Non-Destruct Wire Bond Pull

100%, MIL-STD-883, Method 2023 (2.4 grams)

Internal Visual

MIL-STD-883, methods 2017 & 2032 condition K (class S). During the

time interval between final internal visual inspection and preparation for

sealing, hybrid crystal oscillators shall be stored in a dry, controlled

environment as defined in MIL-STD-883, method 2017 or in a vacuum

bake oven.

Stabilization Bake

48 hrs minimum @ +150°C MIL-STD-883, Method 1008 TC B

Thermal Shock

MI-STD 883, Method 1011, TC A

Temperature Cycling

MI-STD 883, Method 1010, TC B

Constant Acceleration

MIL-STD-883, Method 2001, TC A (5000 gs, Y1 Axis only)

PIND

MIL-STD-883, Method 2020, TC B

Electrical Test

Frequency, Output levels, Input Current@ +25°C

Burn-In (Powered with load)

+125°C for 240 hours

Seal Test (fine & gross)

100% Method 1014, (TC A1 for fine leak and TC C for gross leak)

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical Specification

Radiographic

MIL-STD-883, Method 2012 class S

External visual

MIL-STD-883 Method 2009

ITAR-CONTROLLED Q-TECH PROPRIETARY DO NOT COPY OR DISTRIBUTE WITHOUT Q-TECH APPROVAL