Tvs diode arrays, Lightning surge protection - splv2.8 series, Family of products) – Littelfuse SPLV2.8 Series User Manual

Page 3: Spl v2.8, Product characteristics, Soldering parameters, Application example detail

141

©2012 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to

www.littelfuse.com/SPA

for current information.

TVS Diode Arrays

(SPA

™

Family of Products)

Revision: March 20, 2012

SPLV2.8 Series

SPL

V2.8

Lightning Surge Protection - SPLV2.8 Series

Lead Plating

Matte Tin

Lead Material

Copper Alloy

Lead Coplanarity

0.0004 inches (0.102mm)

Substitute Material

Silicon

Body Material

Molded Epoxy

Flammability

UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte finish VDI 11-13.

Time

T

emperature

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

Preheat

Preheat

Ramp-up

Ramp-up

Ramp-down

Ramp-do

Critical Zone

T

L

to T

P

Critical Zone

T

L

to T

P

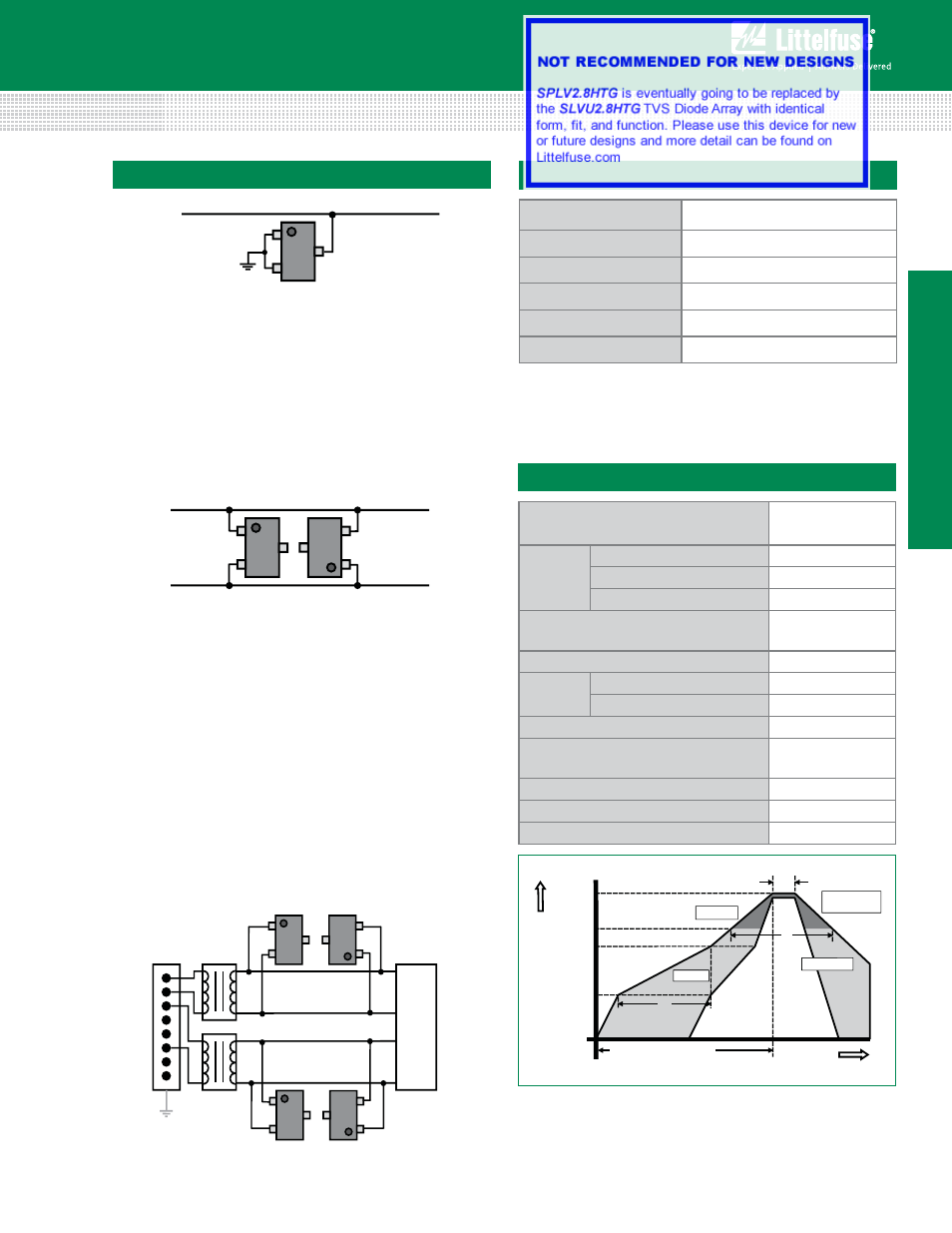

Reflow Condition

Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

)

150°C

- Temperature Max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

L

) to peak

3°C/second max

T

S(max)

to T

L

- Ramp-up Rate

3°C/second max

Reflow

- Temperature (T

L

) (Liquidus)

217°C

- Temperature (t

L

)

60 – 150 seconds

Peak Temperature (T

P

)

260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

20 – 40 seconds

Ramp-down Rate

6°C/second max

Time 25°C to peak Temperature (T

P

)

8 minutes Max.

Do not exceed

260°C

Soldering Parameters

Data Line

Protection of one unidirectional line

Ethernet

PHY

J1

J8

RJ-45

Connector

NC

NC

Protection of one unidirectional data line is realized by

connecting pin 3 to the protected line, and pins 1 and 2 to

GND. In this configuration, the device presents a maximum

loading capacitance of tens of picofarads. During positive

transients, the internal TVS diode will conduct and steer

current from pin 3 to 1 (GND), clamping the data line at or

below the specified voltages for the device (see Electrical

Characteristics section). For negative transients, the internal

compensating diode is forward biased, steering the current

from pin 2 (GND) to 3.

Application Example Detail

Low capacitance protection of a high-speed data pair is

realized by connecting two devices in antiparallel. As shown,

pin 1 of the first device is connected to D1 and pin 2 is

connected to D2. Additionally, pin 2 of the second device is

connected to D1 and pin 1 is connected to D2. Pin 3 must be

NC (or not connected) for both devices. When the potential

on D1 exceeds the potential on D2 (by the rated standoff

voltage), pin 2 on the second device will steer current into

pin 1. The compensating diode will conduct in the forward

direction steering current into the avalanching TVS diode

which is operating in the reverse direction. For the opposite

transient, the first device will behave in the same manner. In

this two device arrangement, the total loading capacitance is

two times the rated capacitance from pin 2 to pin 1 which will

typically be much less than 10pF making it suitable for high-

speed data pair such as 10/100/1000 Ethernet.

NC

Low capacitance protection of one high speed data pair

D1

D2