Poly-fuse, Resettable ptcs, Surface mount > 1812l series – Littelfuse 1812L Series User Manual

Page 3: 181 2l s eries

POLY-FUSE

®

Resettable PTCs

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/05/13

1

81

2L S

eries

Surface Mount > 1812L Series

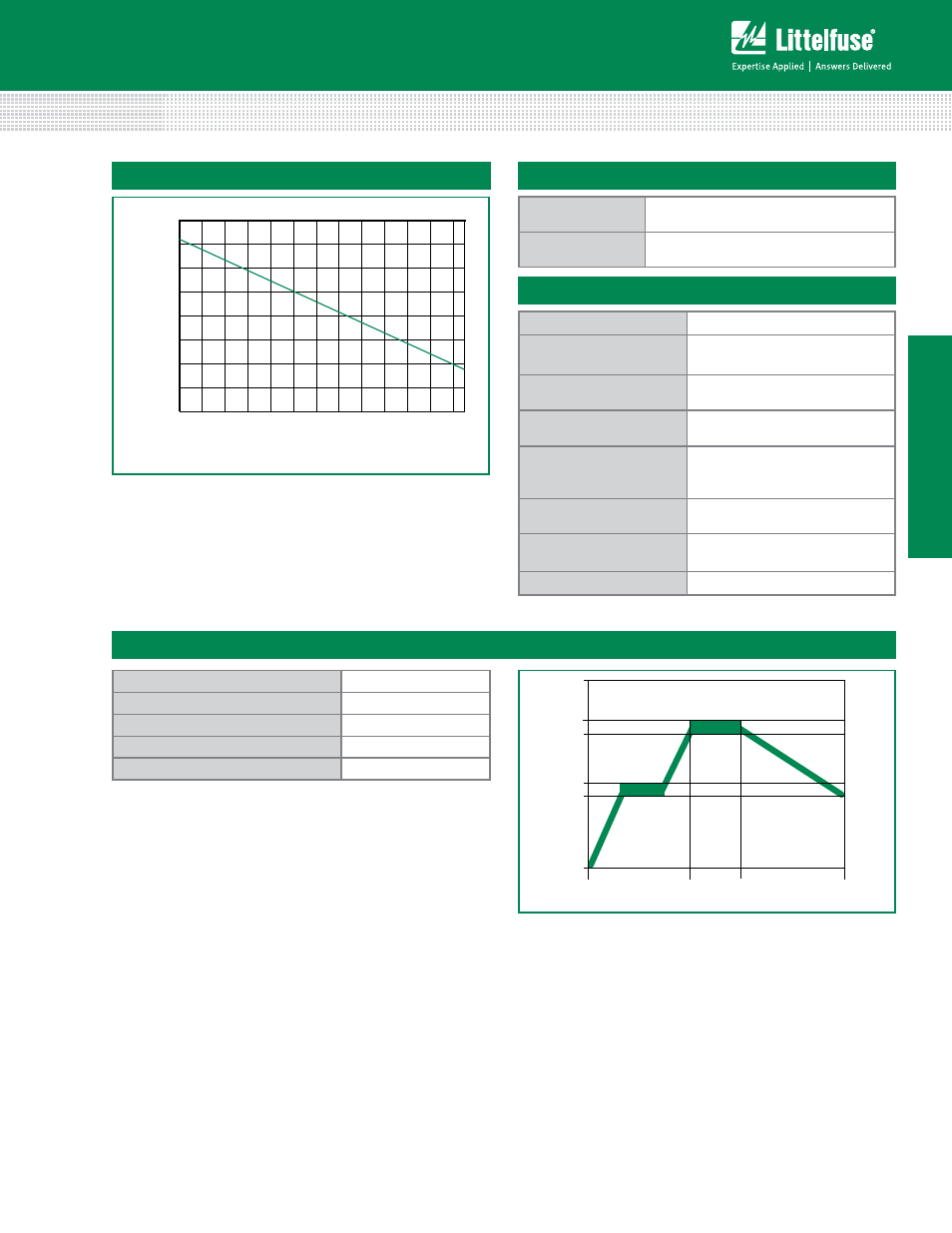

Temperature Rerating Curve

-40 -30 -20 -10

0

10

20 30

40

50

60

70

80 85

10%

30%

50%

70%

90%

110%

130%

150%

170%

Temperature (°C)

Percentage of Rated Current

Environmental Specifications

Operating/Storage Temp.

-40°C to +85°C

Max. Device Surface Temp.

in Tripped State

125°C

Passive Aging

+85°C, 1000 hours

-/+5% typical resistance change

Humidity Aging

+85°C, 85% R.H.,1000 hours

-/+5% typical resistance change

Thermal Shock

MIL–STD–202, Method 107G

+85°C/-40°C 20 times

-30% typical resistance change

Solvent Resistance

MIL–STD–202, Method 215,

No change

Vibration

MIL–STD–883C, Method 2007.1,

Condition A, No change

Moisture Level Sesitivity

Level 1, J–STD–020C

Physical Specifications

Terminal Material

Solder-Plated Copper (Solder Material:

Matte Tin (Sn))

Lead Solderability

Meets EIA Specification RS186-9E, ANSI/

J-STD-002 Category 3.

Soldering Parameters

Condition

Reflow

Peak Temp/ Duration Time

260°C / 10 Sec

Time above liquids (TAL) 220°C

60 Sec ~ 100 Sec

Preheat 120°C~ 180°C

50 Sec ~ 150 Sec

Storage Condition

0°C~35°C, <=70%RH

• Recommended reflow methods: IR, vapor phase oven, hot air

oven, N

2

environment for lead–free

• Recommended maximum paste thickness is 0.25mm (0.010 inch)

• Devices can be cleaned using standard industry methods and

solvents.

Note: If reflow temperatures exceed the recommended profile,

devices may not meet the performance requirements.

Preheating

120

180

220

260

0

60 to 100

Temperature

(°

C)

Soldering

Cooling

120

50 to 150

Time(s)