Tvs diode arrays, General purpose esd protection - sp723 series, Diodes) – Littelfuse SP723 Lead-Free_Green Series User Manual

Page 5: Soldering parameters

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 04/24/13

TVS Diode Arrays

(SPA

®

Diodes)

General Purpose ESD Protection - SP723 Series

Package Dimensions — Dual-In-Line Plastic Packages (PDIP)

Time

Te

mperatur

e

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

Preheat

Preheat

Ramp-up

Ramp-up

Ramp-down

Ramp-do

Critical Zone

T

L

to T

P

Critical Zone

T

L

to T

P

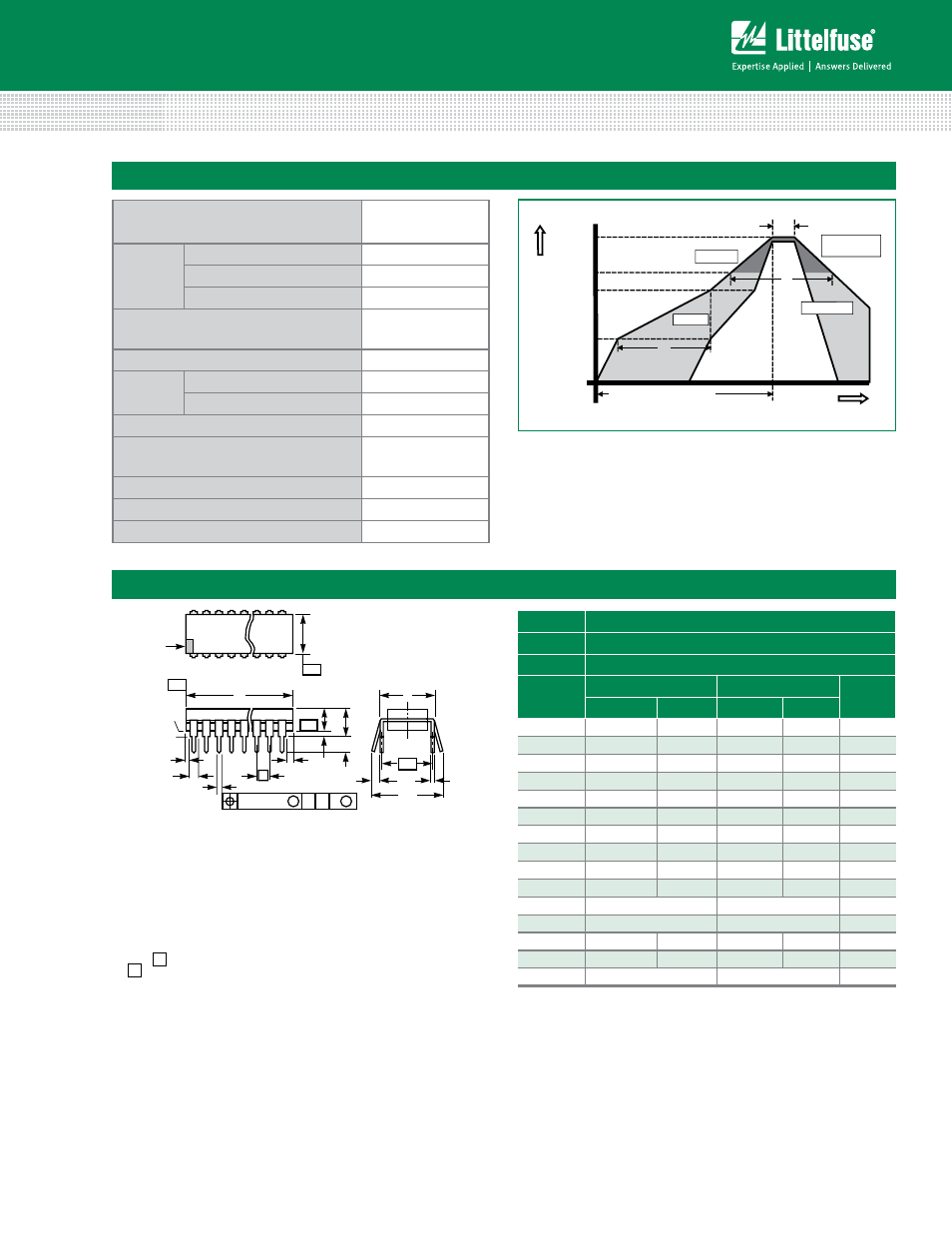

Reflow Condition

Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

)

150°C

- Temperature Max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

L

) to peak

5°C/second max

T

S(max)

to T

L

- Ramp-up Rate

5°C/second max

Reflow

- Temperature (T

L

) (Liquidus)

217°C

- Temperature (t

L

)

60 – 150 seconds

Peak Temperature (T

P

)

260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

20 – 40 seconds

Ramp-down Rate

5°C/second max

Time 25°C to peak Temperature (T

P

)

8 minutes Max.

Do not exceed

260°C

Soldering Parameters

CL

E

e

A

C

e

B

e

C

-B-

E1

INDEX

1 2 3

N/2

N

AREA

SEATING

BASE

PLANE

PLANE

-C-

D1

B1

B

e

D

D1

A

A2

L

A

1

-A-

0.010 (0.25)

C A

M

B S

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protru-

sions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and

are measured with the leads constrained to be per-

pendicular to datum

.

7. e

B

and e

C

are measured at the lead tips with the leads uncon-

strained. e

C

must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

e

A

-C-

Package

PDIP

Pins

8

JEDEC

MS-001

Millimeters

Inches

Notes

Min

Max

Min

Max

A

-

5.33

-

0.210

4

A1

0.39

-

0.015

-

4

A2

2.93

4.95

0.115

0.195

-

B

0.356

0.558

0.014

0.022

-

B1

1.15

1.77

0.045

0.070

8, 10

C

0.204

0.355

0.008

0.014

-

D

9.01

10.16

0.355

0.400

5

D1

0.13

-

0.005

-

5

E

7.62

8.25

0.300

0.325

6

E1

6.1

7.11

0.240

0.280

5

e

2.54 BSC

0.100 BSC

-

e

A

7.62 BSC

0.300 BSC

6

e

B

-

10.92

-

0.430

7

L

2.93

3.81

0.115

0.150

4

N

8

8

9

Notes:

1. Controlling Dimensions: INCH. In case of conflict between English and Metric dimensions,

the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in JEDEC seating plane

gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions. Mold flash or

protrusions shall not exceed 0.010 inch (0.25mm).

6. E and e

A

are measured with the leads unconstrained to be perpendicular to datum

-C- .

7. e

B

and e

C

are measured at the lead tips with the leads uncon-strained. e

C

must be zero or

greater.

8. B1 maximum dimensions do not include dambar protrusions. Dambar protrusions shall not

exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3, E42.6 will have a B1

dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).