Pgr-6150 series, Protection relays & controls, Specifications – Littelfuse PGR-6150 Series User Manual

Page 2: Dynamic thermal modeling, Wiring diagram, Motor protection system

Protection Relays & Controls

© 2013 Littelfuse Protection Relays & Controls

Littelfuse.com/pgr-6150

Features & Benefits

Motor Protection–Standard (PGR 6000 Family)

FeaTuReS

ieee #

beneFiTS

No CTs required

49, 51

No current transformers are required for currents < 25 A

Adjustable trip settings

Adjustable overload trip class setting from 5 to 45 to match motor characteristics

Digital input

Programmable digital input

Output contacts

Two programmable Form C output contacts for operation of separate annunciation and trip circuits

Overload

49, 51

Extends motor life and prevents insulation failures and fires

Overcurrent/Jam

50, 51

Detects catastrophic failures and fires; extends motor life

Undercurrent

37

Detects low level or no-load conditions

Unbalance (current)

46

Prevents overheating due to unbalanced phases

Phase loss/Phase sequence

46

Detects unhealthy supply conditions

PTC overtemperature

49

Detect high ambient or blocked ventilation and single phasing; prevents shaft/pump damage

Dynamic thermal model

Provides protection through starting, running, overload, and cooling cycles

Communications

RS-485 communications to remotely display metered values

Specifications

Protective Functions

(IEEE Device Numbers)

Input Voltage

110-230 Vac/Vdc; 24/48 Vdc, 5 W

AC Measurements

RMS, 16 samples/cycle

Frequency

50, 60 Hz

Dimensions

(Control Unit)

H 83 mm (3.3”); W 78 mm (3.1”); D 99 mm (3.9”)

(Operator Interface)

H 56 mm (2.2”); W 106 mm (4.2”); D 22.8 mm (0.9”)

Output Contacts

Two Form C

Communications

RS-485 with Modbus

®

RTU

Approvals

UL Listed (E353735), CE (European Union)

Warranty

5 years

Mounting

DIN (Control Unit); Panel (Operator Interface)

Overload (49, 51)

Phase sequence (46)

Overcurrent (50, 51)

Jam

Ground fault (50G/N, 51G/N)

Undercurrent (37)

PTC overtemperature (49)

Failure to accelerate

RTD temperature (49)

Unbalance (current) (46)

Starts per hour (66)

Phase loss (current) (46)

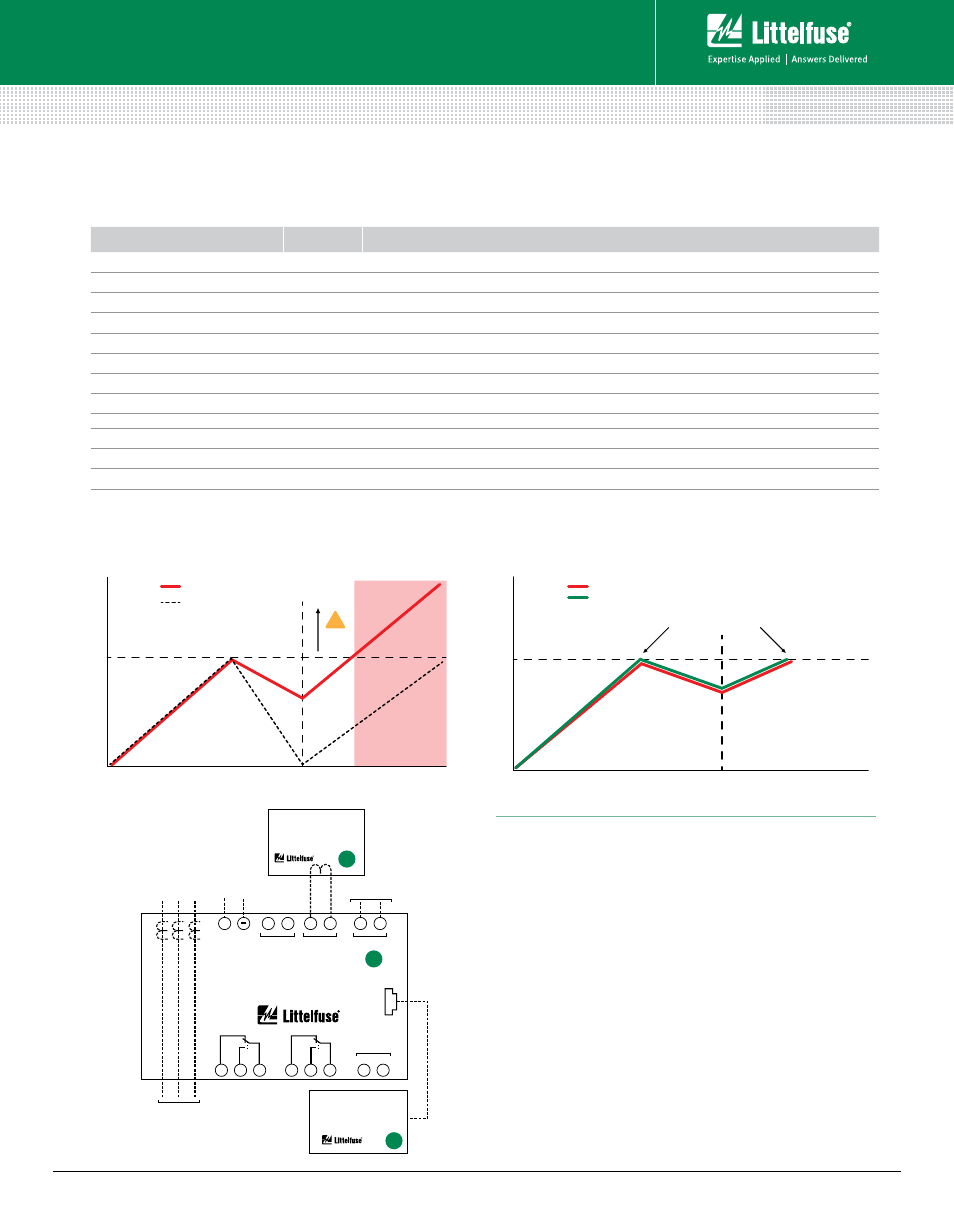

Dynamic Thermal Modeling

Maximum Operating Temperature

Temper

at

ur

e

Time

With PGR-6150 the

temperature is not exceeded,

no damage to motor

Motor

PGR-6150

Maximum Operating Temperature

For every 10°C over

insulation temperature

rating the motor loses

50% of its life span.

Temper

at

ur

e

Time

Motor

Traditional

Overload

!

Da

m

ag

e i

s c

au

se

d,

de

cre

as

es

m

ot

or

lif

e

Tra

dit

ion

al

Ov

erl

oa

d r

es

ets

be

for

e m

oto

r h

as

co

ole

d d

ow

n

With Thermal Memory

Without Thermal Memory

MOTOR PROTECTION SYSTEM

PGR-6150 SERIES

TEMPERATURE

INPUT

DIGITAL

INPUTS

3

4

CT

GF

5

6

PTC

7

8

12

14

11

22

24

21

K1

K2

RS-485

+

–

10

9

CONTROL

POWER

L2/N

L1

GROUND-FAULT

CURRENT TRANSFORMER

PGC-6000 SERIES

FEEDER TO MOTOR

3 PHASE CTs

BUILT INTO RELAY.

EXTERNAL CTs

REQUIRED FOR

FLA >25 A.

OPERATOR INTERFACE

PGR-6150-OPI

+

(optional)

(optional)

Wiring Diagram

B

A

1

PGR-6150 SeRieS

Motor Protection System

Rev: 4-A-050213

Based on Manual Rev 1