Tvs diode arrays, General purpose esd protection - sp1001 series, Diodes) – Littelfuse SP1001 Series User Manual

Page 2

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 10/10/13

TVS Diode Arrays

(SPA

®

Diodes)

General Purpose ESD Protection - SP1001 Series

Absolute Maximum Ratings

Symbol

Parameter

Value

Units

I

PP

Peak Current (t

p

=8/20μs)

2

A

T

OP

Operating Temperature

–40 to 125

°C

T

STOR

Storage Temperature

–55 to 150

°C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational sections of this

specification is not implied.

Electrical Characteristics (T

OP

= 25°C)

Parameter

Symbol

Test Conditions

Min

Typ

Max

Units

Forward Voltage Drop

V

F

I

F

=10mA

0.7

0.9

1.2

V

Reverse Voltage Drop

V

R

I

R

=1mA

6.0

8.5

V

Reverse Standoff Voltage

V

RWM

I

R

≤1µA

5.5

V

Reverse Leakage Current

I

LEAK

V

R

=5V

0.5

µA

Clamp Voltage

1

V

C

I

PP

=1A, t

p

=8/20µs, Fwd

8.0

11.0

V

I

PP

=2A, t

p

=8/20µs, Fwd

9.7

13.0

V

Dynamic Resistance

R

DYN

(V

C2

- V

C1

) / (I

PP2

- I

PP1

)

1.7

Ω

ESD Withstand Voltage

1,2

V

ESD

IEC61000-4-2 (Contact)

±15

kV

IEC61000-4-2 (Air)

±30

kV

Diode Capacitance

1

C

D

Reverse Bias=0V

12

pF

Reverse Bias=2.5V

8

pF

Reverse Bias=5V

7

pF

Notes:

1

Parameter is guaranteed by device characterization

2

A minimum of 1,000 ESD pulses are applied at 1s intervals between the anode and common cathode of each diode

Thermal Information

Parameter

Rating

Units

Storage Temperature Range

–55 to 150

°C

Maximum Junction Temperature

150

°C

Maximum Lead Temperature (Soldering

20s-40s)

260

°C

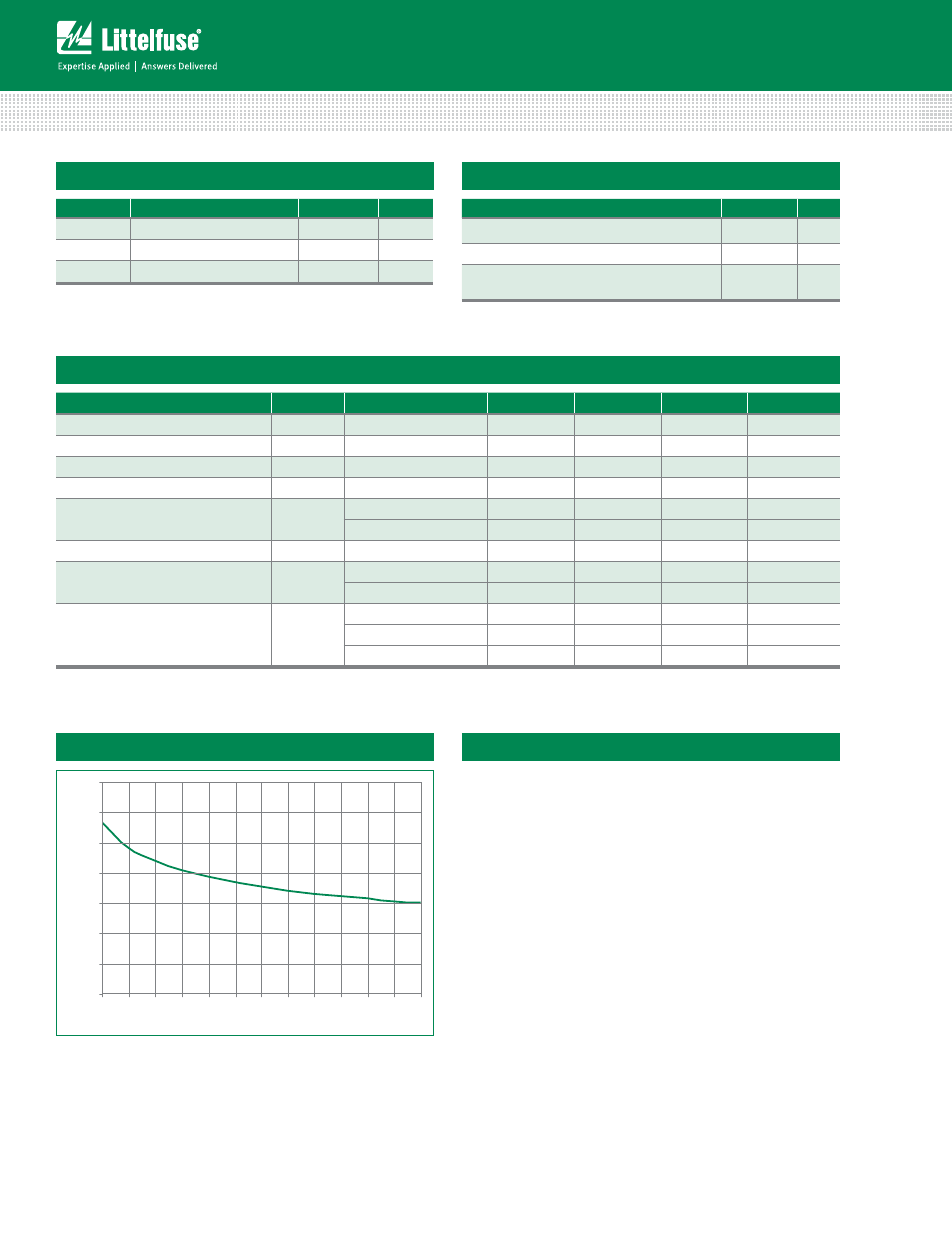

Capacitance vs. Reverse Bias

0

2

4

6

8

10

12

14

DC Bias (V)

Capacitance (pF)

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

Design Consideration

Because of the fast rise-time of the ESD transient,

placement of ESD devices is a key design consideration.

To achieve optimal ESD suppression, the devices should be

placed on the circuit board as close to the source of the ESD

transient as possible. Install the ESD suppressors directly

behind the connector so that they are the first board-level

circuit component encountered by the ESD transient. They

are connected from signal/data line to ground.