Varistor products, 34s series, Hi–en e rgy mo v’s – Littelfuse TMOV 34S Varistor Series User Manual

Page 5: Tmov, 34s s eries pulse rating curve, V–i characteristic curves for tmov, 34s varistor, Series tmov

© 2013 Littelfuse, Inc.

227

Revised: December 16, 2013

Varistor Products

TMOV

®

34S Varistor Series

Industrial High Energy Thermally Protected Varistors > TMOV

®

34S Series

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/tmov34s.html for current information.

Hi–En

E

rgy Mo

V’s

TMOV

®

34S S

eries

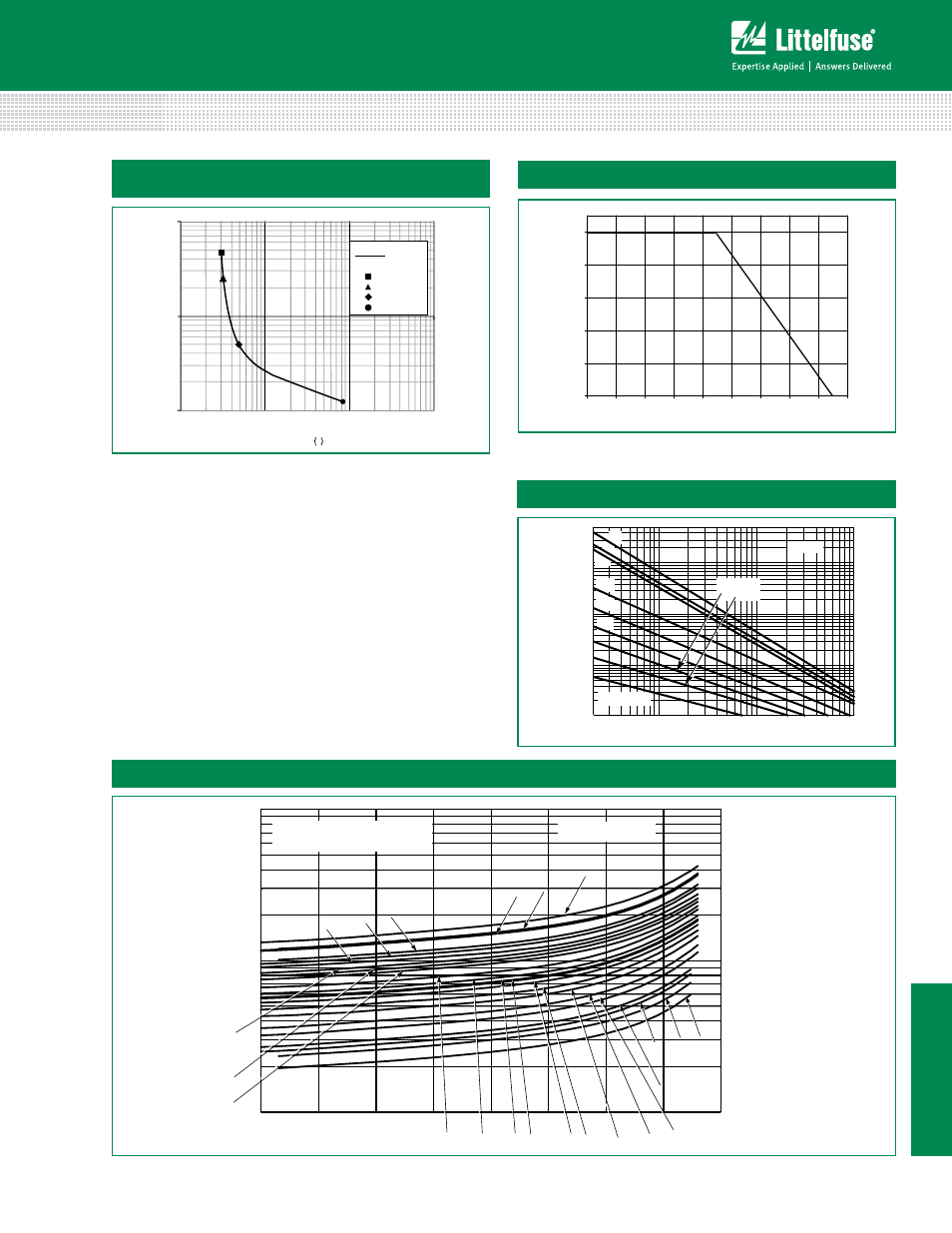

Pulse Rating Curve

FIGURE 6. SURGE CURRENT RATING CURVES FOR

HB34, HF34 and HG34

Hx34

50,000

20,000

10,000

5,000

2,000

1,000

500

200

100

50

20

10

20

100

1,000

10,000

SUR

GE CURRENT (A)

IMPULSE DURATION ( µs)

15

1

INDEFINITE

105

102

2

103

104

106

Peak Current & Energy Derating Curve

Typical time to open circuit under UL1449 Abnormal

Overvoltage Limited Current Test

* Figure 4: Typical time to open circuit under UL1449

Abnormal Overvoltage Limited Current Test

0.1

1

10

10

100

1000

10000

Time s

0.125A

0.5A

2.5A

5A

Typical

V–I Characteristic Curves for TMOV

®

34S Varistor

1000

10000

1mA

10mA

100mA

1A

10A

100A

10000A

100000A

TA = -55 C to 85C

V751

V681

V661

V571

V551

V511

V391

V351 V331 V321

V271

V251 V201 V181

V151

V141

V111

V131

V301

V481

V461

V421

100

1000A

Maximum Clamping Voltage

TMOV34S series

Current - AMPS

Voltage -

VOLTS

Note: The Industrial TMOV

®

Series TMOV

®

34S devices

are intended, in conjunction with appropriate enclosure

design, to help facilitate SPD module compliance to

UL 1449, Section 37.4 (Abnormal Overvoltage Limited

Current Requirements). Under these extreme abnormal

overvoltage conditions, the units will exhibit substantial

heating and potential venting prior to opening. Modules

should be designed to contain this possibility. Application

testing is strongly recommended.

For applications exceeding 85ºC ambient temperature, the peak

surge current and energy ratings must be reduced as shown.

For applications exceeding 85˚C ambient

temperature, the peak surge current and energy

ratings must be reduced as shown in Figure 5.

Figure 5: Peak Current & Energy Derating Curve

0

20

40

60

80

100

-55

50

60

70

80

90

100

110

120

130

AMBIENT TEMPERATURE (ºC)

PERCENT OF RATED VALU

E

Figure 1

Figure 2

Figure 3

Figure 4