Axial lead & cartridge fuses, Average time current curves, Temperature rerating curve – Littelfuse 313 Series User Manual

Page 3: Soldering parameters - wave soldering

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Axial Lead & Cartridge Fuses

3AG > Time Lag > 313/315 Series

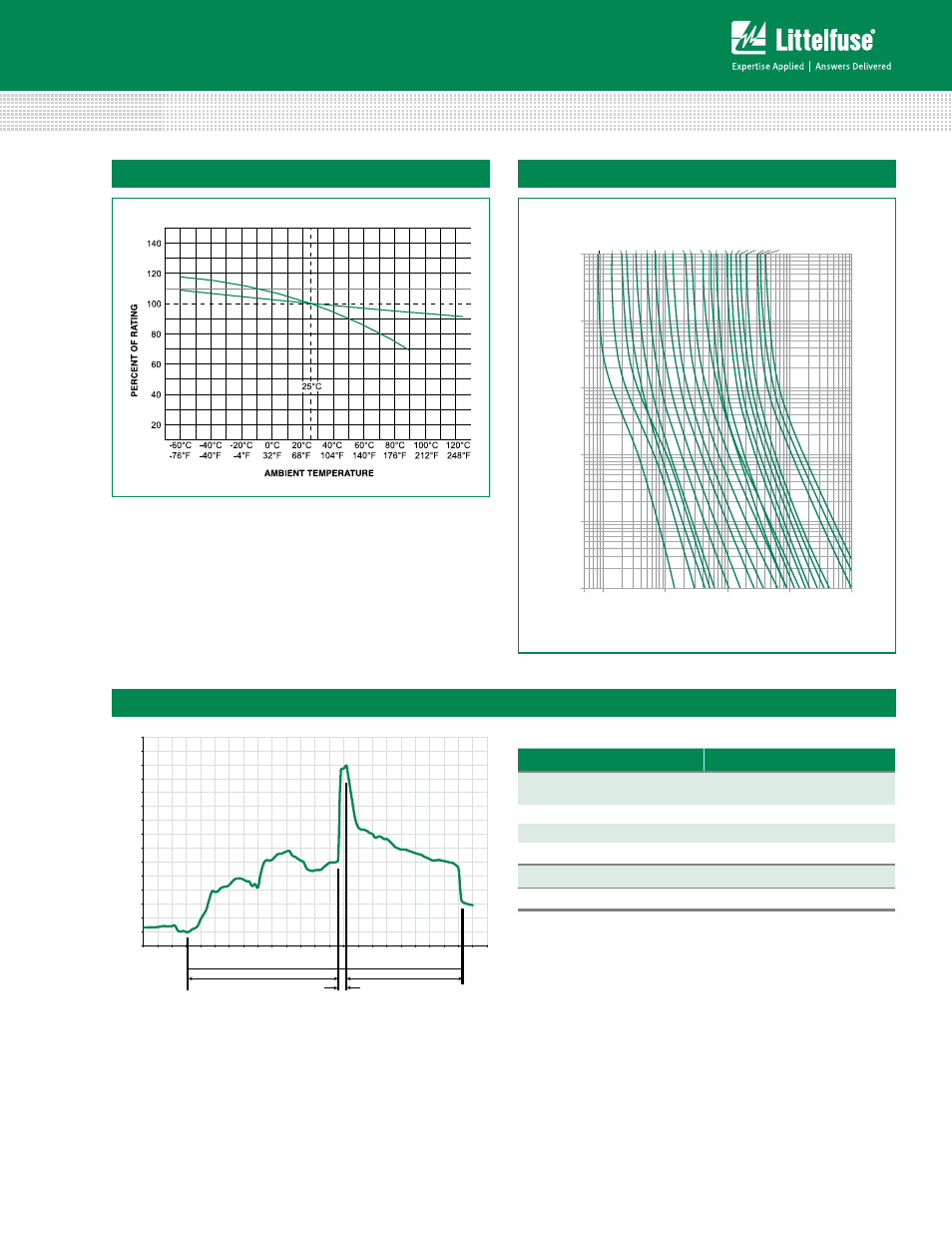

Average Time Current Curves

1000

100

10

1

0.1

0.01

1/16A

0.05 0.1

1

10

100

1000

1/10A 15/100A .175A 1/4A 3/8A 1/2A 3/4A 1A 1 1/2A 2A 3A 4A 5A 7A 8A 10A 12A 15A 20A

30A

25A

TIME IN SECONDS

CURRENT IN AMPERES

Temperature Rerating Curve

A

B

A

B

Soldering Parameters - Wave Soldering

Dwell Time

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

Time (Seconds)

Temperature (°C) - Measured on bottom side of board

Cooling Time

Preheat Time

Wave parameter

lead-Free Recommendation

preheat:

(Depends on Flux Activation Temperature)

(Typical Industry Recommendation)

Temperature Minimum:

100

°

C

Temperature Maximum:

150

°

C

Preheat Time:

60-180 seconds

Solder pot Temperature:

260

°

C Maximum

Solder Dwell Time:

2-5 seconds

Recommended Hand-Solder Parameters:

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Note: These devices are not recommended for IR or

Convection Reflow process.

Recommended Process Parameters:

A - For 313/315 Series, from 10mA to 150mA

B - For all other ampere ratings of 313/315 series