Use good connectors – Crown Audio Com-Tech "00 Series" User Manual

Page 19

Page 19

Com-Tech 200/400/800/1600 Power Amplifiers

40

30

20

15

10

9

8

7

6

5

4

3

2

1

2

5

10

20

50

100

.04

.06

.1

.2

.4

.6

1

2

4

6

10

20

40

5

10

20

50

1

2

100

200

500

1000

2000

5000

8000

5000

1000

500

100

50

10

5

1

.5

.1

.05

.01

#28

#26

#24

#22

#20

#18

#16

#14

#12

#10

#8

#6

#4

#2

#0

#00

#0000

R

LOAD

RESISTANCE

(ohms)

L

R

R

DAMPING

FACTOR

L

S

R

SOURCE

RESISTANCE

(ohms)

S

2-COND.

CABLE

(feet)

ANNEALED

COPPER

WIRE

(AWG)

(ohms/1000 ft.)

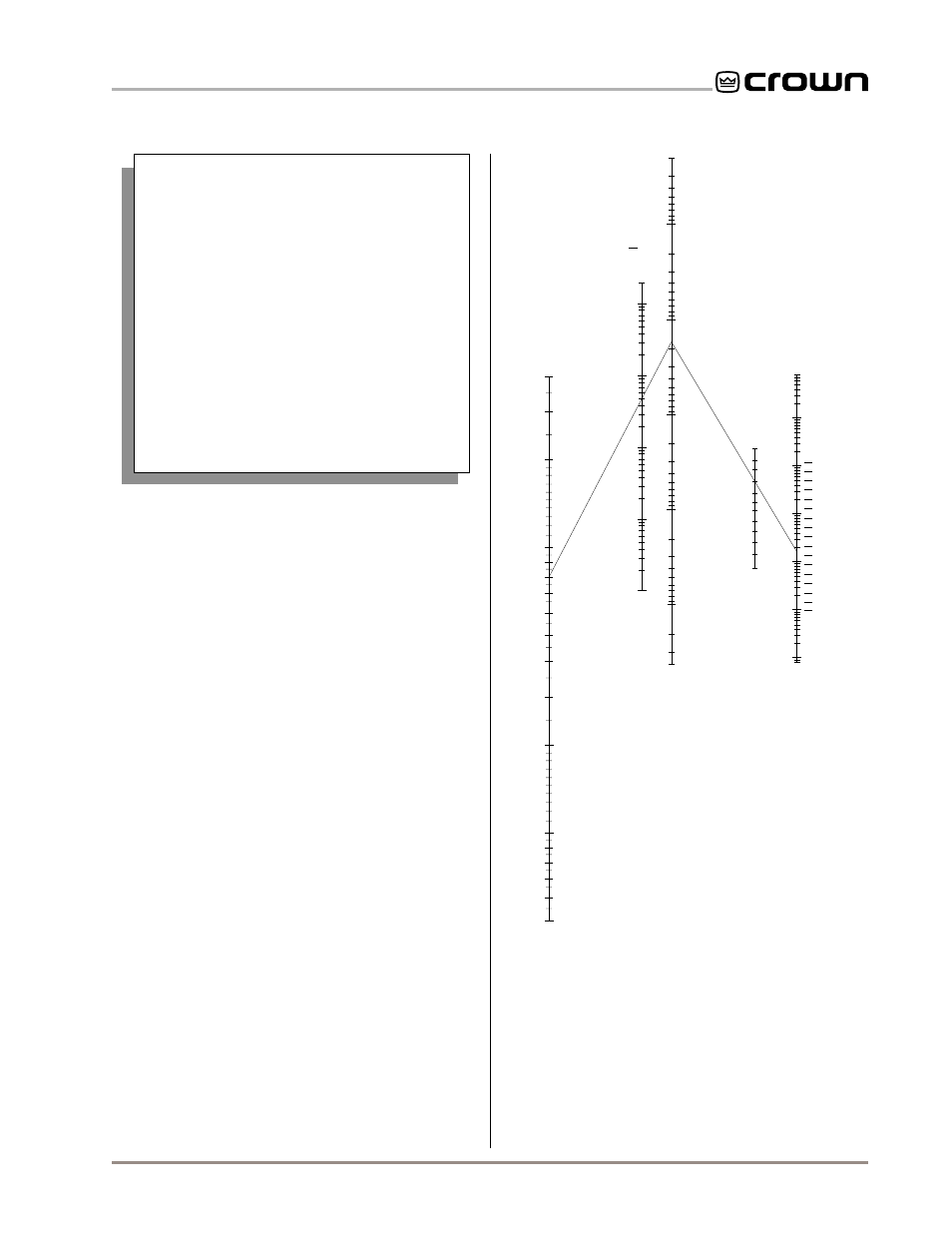

Example Shown:

R = 8 ohms; R = 0.016 ohms or D.F. = 500;

Cable Length = 10 ft.; answer: #8 wire

L

S

1

0.5

200

500

1,000

2,000

20,000

5,000

10,000

.01

.001

.02

.004

.006

.002

.0004

.0006

.0002

0.6

0.7

0.8

1.5

0.9

tion 4.1,

Precautions.

You should always install loudspeaker cables of suffi-

cient gauge (wire thickness) for the length used. The

resistance introduced by inadequate output cables

will reduce the amplifier’s power to and motion control

of the loudspeakers. The latter problem occurs be-

cause the damping factor decreases as the cable re-

sistance increases. This is very important because the

amplifier’s excellent damping factor can be easily ne-

gated by using insufficient cable.

Use the nomograph in Figure 3.13 and the following

procedure to find the recommended wire gauge (AWG

or American Wire Gauge) for your system.

1. Note the load resistance of the loudspeakers con-

nected to each channel of the amplifier. If you are using

70 volt output, be sure to determine the load resistance of

the step-down transformers (Crown’s constant voltage

computer can help with this, see Section 8.3). Mark this

value on the “Load Resistance” line of the nomograph.

2. Select an acceptable damping factor and mark it on

the “Damping Factor” line. Your amplifier can provide an

excellent damping factor of 1,000 from 10 to 400 Hz in

Stereo mode with an 8 ohm load. In contrast, typical

damping factors are 50 or lower. Higher damping factors

yield lower distortion and greater motion control over the

loudspeakers. A common damping factor for commercial

applications is between 50 and 100. Higher damping fac-

tors may be desirable for live sound, but long cable

lengths often limit the highest damping factor that can be

achieved practically. (Under these circumstances,

Crown’s

IQ System is often used so amplifiers can be eas-

ily monitored and controlled when they are located very

near the loudspeakers.) In recording studios and home

hi-fi, a damping factor of 500 or more is very desirable.

Use Good Connectors

1. To prevent possible short circuits, do not

expose the loudspeaker cable connectors.

2. Do not use connectors that might acciden-

tally tie two channels together when making or

breaking connections (for example, a stan-

dard three-wire stereo phone plug).

3. Connectors that can be plugged into AC

power receptacles should never be used.

4. Connectors with low current-carrying ca-

pacity should not be used.

5. Connectors with any tendency to short

should never be used.

3. Draw a line through the two points with a pencil, and

continue until it intersects the “Source Resistance” line.

4. On the “2-Cond. Cable” line, mark the length of the

cable run.

5. Draw a pencil line from the mark on the “Source Resis-

tance” line through the mark on the “2-Cond. Cable” line,

and on to intersect the “Annealed Copper Wire” line.

6. The required wire gauge for the selected wire length and

Fig. 3.13 Wire Size Nomograph