R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Elite Manual User Manual

Page 24

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

!

: (937) 328-5100

FAX: (937) 325-5319

24/31

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

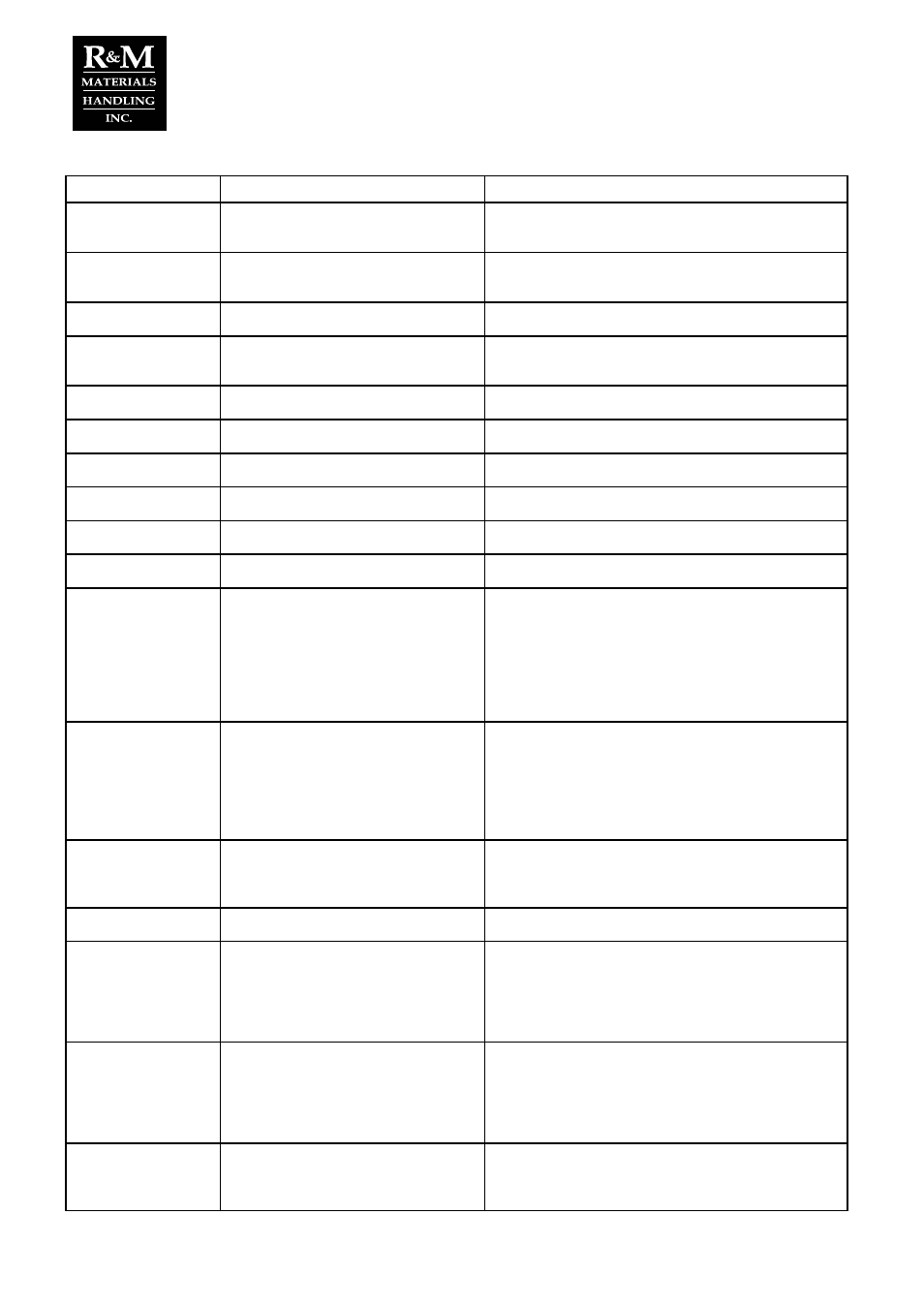

Fault code

Possible cause

Checking

F 24

Changed data

warning

Changes may have occurred in the

different counter data due to mains

interruption

No special actions required. Take a critical attitude to

the counter data.

F 25

Microprocessor

watchdog-fault

− interference fault

− component failure (control unit)

If the fault comes again, contact authorized service.

F 26

Power Unit Fault

F 32

Fan cooling fault

Cooling fan of the frequency converter

do not work, when ON command has

been given

If the fault comes again, contact authorized service.

F 35

Application fault

Run-time exception in the application

program

Contact authorized service.

F 36

Control Unit

Faulty Control Unit.

Contact authorized service.

F 37

Device changed

Option board changed. Different power

rating of drive

Reset the fault.

F 38

Device added

Option board added. Drive of different

power rating added

Reset the fault.

F 39

Device removed

Option board removed. Drive removed

Reset the fault.

F 40

Device unknown

Unknown option board or drive.

Check board and drive type.

F 41

IGBT temperature

Too high temperature in IGBT

transistors.

− long duration overload

− lowered cooling

− high environment temperature

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

motor loading

− brake operation

− inverter heatsink

− inverter cooling fan operation

− environment temperature

F 43

Encoder failure

Encoder failure.

− Code1 = EA+/- is missing

− Code2 = EB+/- is missing

− Code3 = Both EA+/- and EB+/- are

missing

− Code4 = EA+ and EB+ are

crossconnected

Check:

− encoder cabling

− brake opening

− encoder mechanical assembly

− encoder type and pulse number

F 50

Reference value fault

Analog input signal is out of selected

range 1-9V or 2-10V

− control cable is broken

− signal source has failed

Check

− reference cable

− reference source

F 51

Stop limit

Stop limit has tripped

Reset: keep controller at zero >300ms.

Ensure that fault disappears after leaving the stop limit.

F 53

Profibus

communication error

Watchdog time out in Profibus

communication. Effective only if control

through Profibus is selected. Poor

Profibus cable connection or

communication problems with Profibus

master.

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

− Profibus slave address

− Profibus cable connection

− Profibus termination resistor settings

F 55

Board Fault

Some of following board is missing:

− A = Basic I/O board

− B = Thermistor board

− C = SSU (in closed loop and

hoisting applications)

Reset: switch power off and restart after the lamps of

keypad are off.

Check

− board slots A, B and C

− drive selection

− control mode

F 56

Generator side

current limit

Open loop frequency control only. Too

short deceleration time or open loop

generator side current limit is too low.

Reset has an additional 5 s time delay.

Check:

− deceleration time

− current limit setting