R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Elite Manual User Manual

Page 23

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

!

: (937) 328-5100

FAX: (937) 325-5319

23/31

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

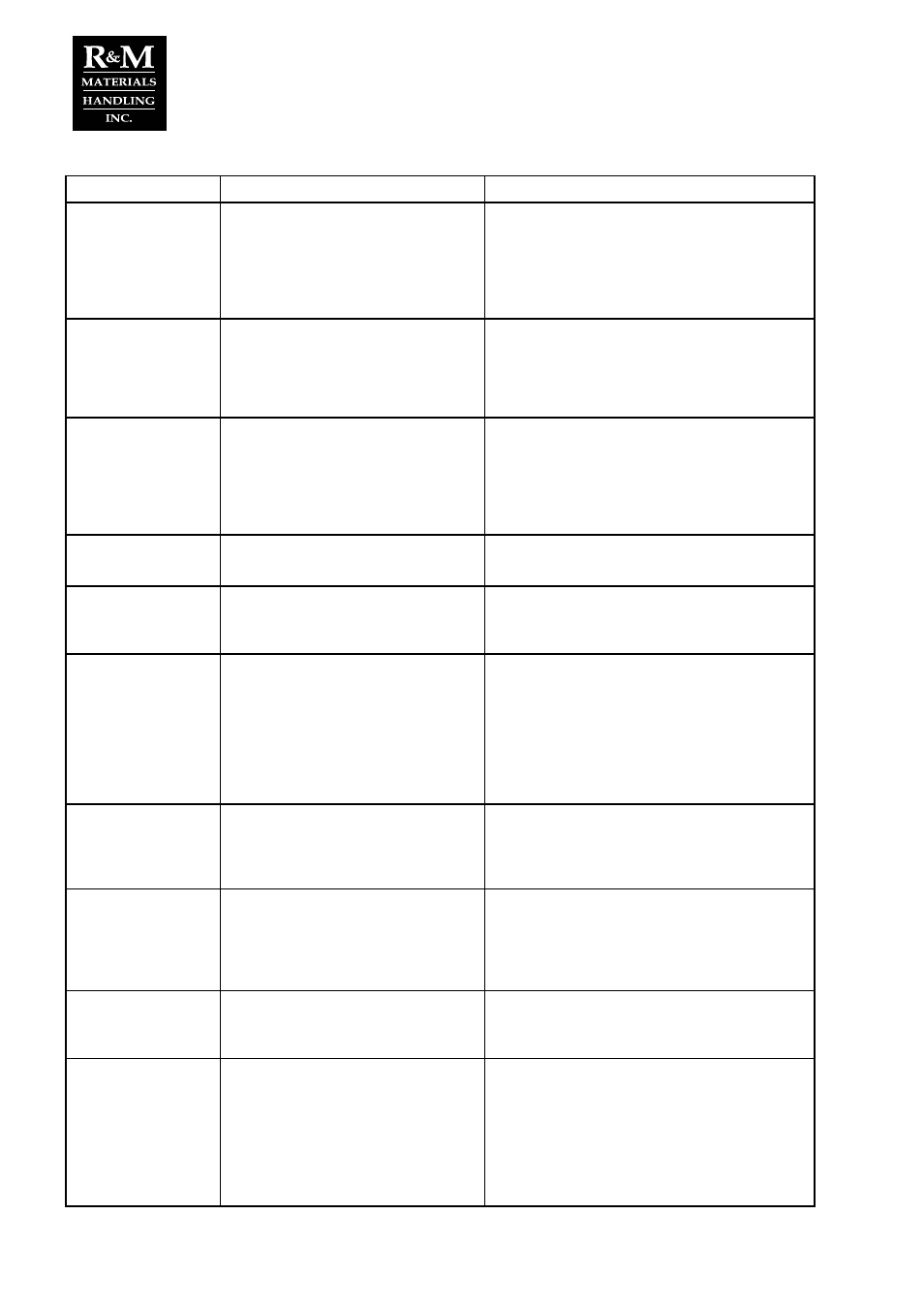

Fault code

Possible cause

Checking

F 7

Saturation trip

Very high overload or defective

component

Reset: switch power off and restart after the lamps

of keypad are off.

Check:

− motor and motor cable insulation

− measure main circuit diodes and IGBT

transistors

If the fault comes again, change the D2V.

F8

System fault

System fault due to component failure

or faulty operation.

Reset: switch power off and restart after the lamps

of keypad are off.

Check:

− read fault extension code and contact

authorized service

If the fault comes again, change the D2V.

F 9

Undervoltage

DC-bus voltage has dropped below

333Vdc

− mains supply voltage interrupted

− inverter fault can also cause an

undervoltage trip

− external fault during run may cause

an undervoltage trip

In case of temporary supply voltage break, reset

the fault and start again. Check mains input.

− if mains supply is correct, an internal failure

has occurred

− contact authorized service

F 10

Input line supervision

One input line phase is missing or

supply voltage parameter is wrong

Check:

− supply voltage

− mains connection

F 11

Output phase

supervision

Current supervision has sensed that

one of the motor phases has no current

Check:

− motor cable connections

− measure motor phase currents and compare to

display value

F 12

Braking chopper

supervision

Braking chopper or braking resistor

circuit has failed. Fault appears if

− braking resistor is broken

− braking chopper is broken

− braking resistor is not installed

Reset: switch power off and restart after the lamps

of keypad are off.

Check:

− braking resistor and cable resistance and

insulation resistance

− measure braking transistor IGBT and free

wheeling diodes

− if resistor is OK, then the chopper is broken

− contact authorized service

F 13

Inverter

undertemperature

Temperature of heat sink is below

acceptable operating level (-10°C

/14°F)

Check

− ambient temperature

− cubicle heating

− inverter cooling fan activation (continuous /

temperature limit)

F 14

Inverter

overtemperature

Temperature of heat sink is over

acceptable operating level

+90°C (194°F).

Overtemperature warning is issued

when the heat sink temperature

exceeds +85°C (185°F)

Check:

− ambient temperature

− inverter cooling fan operation

− cooling air flow through heat sink

− heat sink is not dusty

F16

Motor

overtemperature

Mathematical motor temperature model

has detected motor overheating. Motor

is overloaded.

Check:

− motor load

− if no overload exists, then check motor

temperature model parameters

F 22

F 23

EEPROM checksum

fault

Parameter save error

− interference fault

− component failure (control unit)

After power off the inverter will automatically load

factory default parameter settings. D2H/D2C does

not work properly nor enable driving after this

fault.

Check:

− all parameter settings

− +24V voltage output loading

If the fault comes again, contact authorized

service.