Chip information, Pin configuration – Rainbow Electronics MAX1844 User Manual

Page 21

Therefore, V

IN

must be greater than 3.13V, even with

very large output capacitance, and a practical input volt-

age with reasonable output capacitance would be 3.48V.

PC Board Layout Guidelines

Careful PC board layout is critical to achieving low

switching losses and clean, stable operation. The switch-

ing power stage requires particular attention (Figure 9). If

possible, mount all of the power components on the top

side of the board, with their ground terminals flush

against one another. Follow these guidelines for good

PC board layout:

• Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable,

jitter-free operation.

• Keep the power traces and load connections short.

This practice is essential for high efficiency. Using

thick copper PC boards (2oz vs. 1oz) can enhance

full-load efficiency by 1% or more. Correctly routing

PC board traces is a difficult task that must be

approached in terms of fractions of centimeters,

where a single milliohm of excess trace resistance

causes a measurable efficiency penalty.

• Minimize current sensing errors by connecting CS

directly to the R

SENSE

terminal.

• When trade-offs in trace lengths must be made, it is

preferable to allow the inductor charging path to be

made longer than the discharge path. For example,

it is better to allow some extra distance between the

input capacitors and the high-side MOSFET than to

allow distance between the inductor and the low-

side MOSFET or between the inductor and the out-

put filter capacitor.

• Route high-speed switching nodes (BST, LX, DH, and

DL) away from sensitive analog areas (REF, FB, CS).

Layout Procedure

1) Place the power components first, with ground termi-

nals adjacent (Q2 source, C

IN-

, C

OUT-

, D1 anode). If

possible, make all these connections on the top layer

with wide, copper-filled areas.

2) Mount the controller IC adjacent to MOSFET Q2,

preferably on the back side opposite Q2 in order to

keep LX, GND, and the DL gate-drive lines short and

wide. The DL gate trace must be short and wide,

measuring 10 to 20 squares (50 to 100 mils wide if the

MOSFET is 1 inch from the controller IC GND pin.

3) Group the gate-drive components (BST diode and

capacitor, V

DD

bypass capacitor) together near the

controller IC.

4) Make the DC-DC controller ground connections as

shown in Figure 9

.

This diagram can be viewed as

having two separate ground planes: power ground,

where all the high-power components go; and an ana-

log ground plane for sensitive analog components.

The analog ground plane and power ground plane

must meet only at a single point directly at the IC.

5) Connect the output power planes directly to the out-

put filter capacitor positive and negative terminals

with multiple vias. Place the entire DC-DC converter

circuit as close to the load as is practical.

MAX1844

High-Speed Step-Down Controller with

Accurate Current Limit for Notebook Computers

______________________________________________________________________________________

21

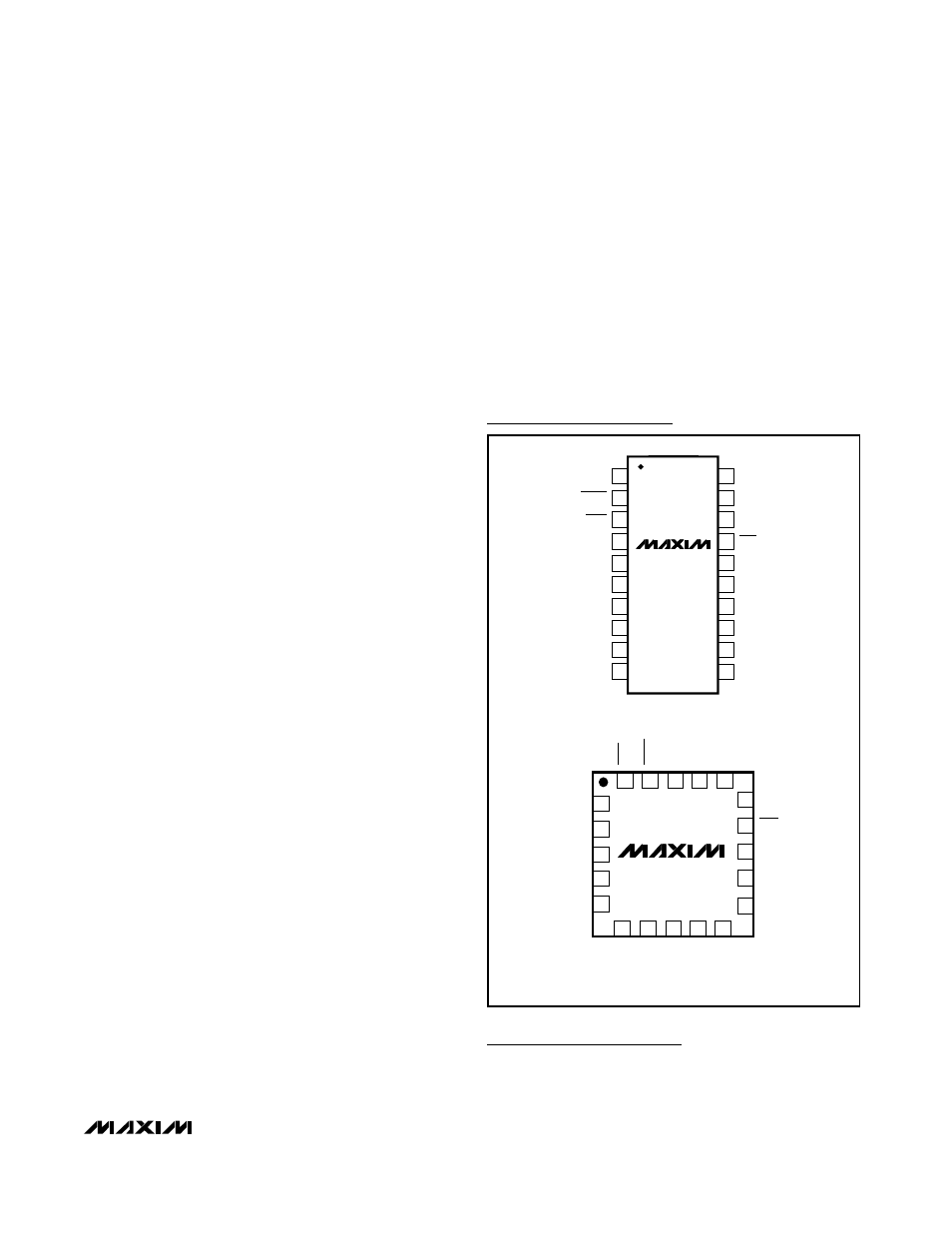

Chip Information

TRANSISTOR COUNT: 2963

PROCESS: BiCMOS

Pin Configuration

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

DH

LX

BST

SKIP

OVP

SHDN

LATCH

CS

TOP VIEW

V+

TON

V

CC

V

DD

REF

ILIM

OUT

FB

12

11

9

10

DL

GND

PGOOD

UVP

MAX1844EEP

20 QSOP

3

2

1

20

19

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20 QFN

MAX1844EGP

V

CC

TON

V+

SKIP

BST

REF

ILIM

OUT

FB

OVP

LX

DH

CS

LATCH

SHDN

V

DD

DL

GND

PGOOD

UVP