Design procedure – Rainbow Electronics MAX1715 User Manual

Page 17

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________

17

Overvoltage protection can be defeated through the

SKIP test mode (Table 3).

Output Undervoltage Protection (UVP)

The output undervoltage protection function is similar to

foldback current limiting, but employs a timer rather

than a variable current limit. If the MAX1715 output volt-

age is under 70% of the nominal value 20ms after com-

ing out of shutdown, the PWM is latched off and won’t

restart until V

CC

power is cycled or SHDN is toggled.

No-Fault Test Mode

The over/undervoltage protection features can compli-

cate the process of debugging prototype breadboards

since there are (at most) a few milliseconds in which to

determine what went wrong. Therefore, a test mode is

provided to totally disable the OVP, UVP, and thermal

shutdown features, and clear the fault latch if it has

been set. The PWM operates as if SKIP were grounded

(PFM/PWM mode).

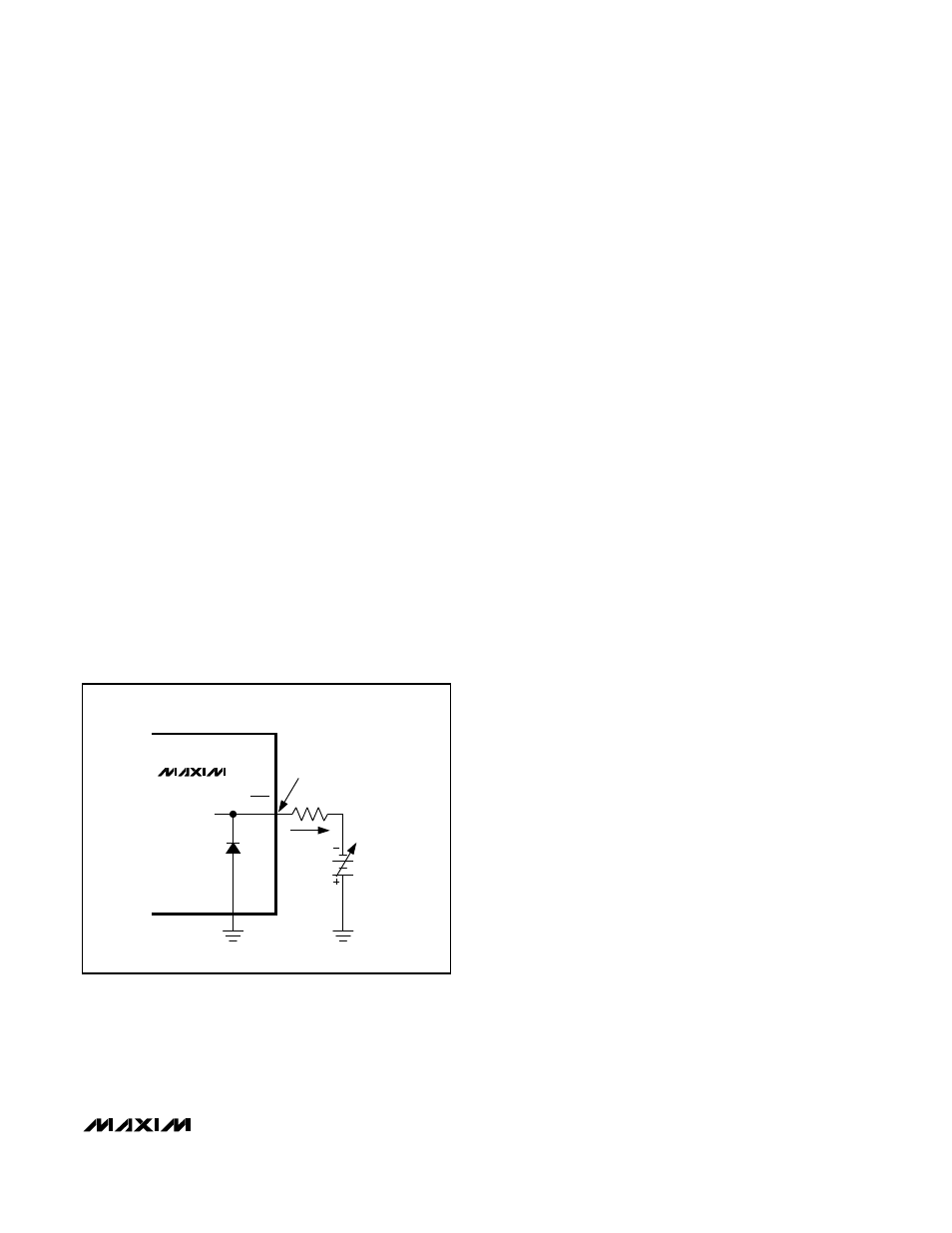

The no-fault test mode is entered by sinking 1.5mA

from SKIP through an external negative voltage source

in series with a resistor (Figure 7). SKIP is clamped to

AGND with a silicon diode, so choose the resistor value

equal to (V

FORCE

- 0.65V) / 1.5mA.

__________________Design Procedure

Firmly establish the input voltage range and maximum

load current before choosing a switching frequency

and inductor operating point (ripple-current ratio). The

primary design trade-off lies in choosing a good switch-

ing frequency and inductor operating point, and the fol-

lowing four factors dictate the rest of the design:

1) Input voltage range. The maximum value (V

IN(MAX)

)

must accommodate the worst-case high AC adapter

voltage. The minimum value (V

IN(MIN)

) must account

for the lowest battery voltage after drops due to con-

nectors, fuses, and battery selector switches. If

there is a choice at all, lower input voltages result in

better efficiency.

2) Maximum load current. There are two values to

consider. The peak load current (I

LOAD(MAX)

) deter-

mines the instantaneous component stresses and fil-

tering requirements, and thus drives output

capacitor selection, inductor saturation rating, and

the design of the current-limit circuit. The continuous

load current (I

LOAD

) determines the thermal stresses

and thus drives the selection of input capacitors,

MOSFETs, and other critical heat-contributing com-

ponents. Modern notebook CPUs generally exhibit

I

LOAD

= I

LOAD(MAX)

· 80%.

3) Switching frequency. This choice determines the

basic trade-off between size and efficiency. The

optimal frequency is largely a function of maximum

input voltage, due to MOSFET switching losses that

are proportional to frequency and V

IN

2. The opti-

mum frequency is also a moving target, due to rapid

improvements in MOSFET technology that are mak-

ing higher frequencies more practical (Table 4).

4) Inductor operating point. This choice provides

trade-offs between size vs. efficiency. Low inductor

values cause large ripple currents, resulting in the

smallest size, but poor efficiency and high output

noise. The minimum practical inductor value is one

that causes the circuit to operate at the edge of criti-

cal conduction (where the inductor current just

touches zero with every cycle at maximum load).

Inductor values lower than this grant no further size-

reduction benefit.

The MAX1715’s pulse-skipping algorithm initiates

skip mode at the critical conduction point. So, the

inductor operating point also determines the load-

current value at which PFM/PWM switchover occurs.

The optimum point is usually found between 20%

and 50% ripple current.

APPROXIMATELY

-0.65V

1.5mA

V

FORCE

SKIP

AGND

MAX1715

Figure 7. Disabling Over/Undervoltage Protection (Test Mode)