Max1802 digital camera step-down power supply, Pin description (continued) – Rainbow Electronics MAX1802 User Manual

Page 13

MAX1802

Digital Camera Step-Down

Power Supply

______________________________________________________________________________________

13

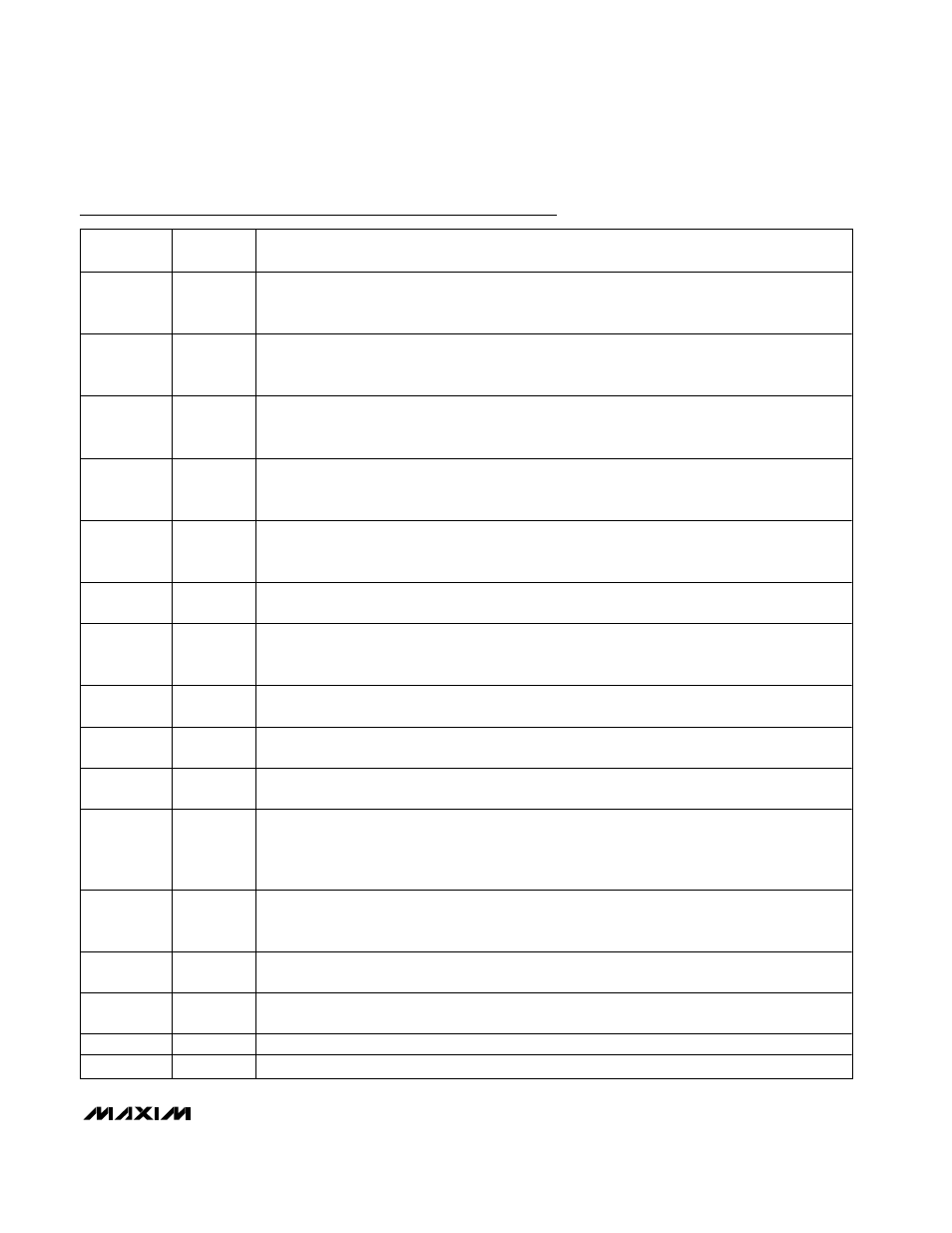

PIN

NAME

FUNCTION

17

COMP2

Compensation for Auxiliary Controller 2. Output of auxiliary controller 2 transconductance error

amplifier. Connect a series resistor and capacitor from COMP2 to GND to compensate the auxiliary

controller 2 control loop (see Compensation Design).

18

DCON2

Maximum Duty Cycle Control Input for Auxiliary Controller 2. Connect DCON2 to VL to set the default

maximum duty cycle. Connect a resistive voltage-divider from REF to DCON2 to set the maximum

duty cycle between 40% and 90%. Pull DCON2 below 300mV to turn the controller off.

19

DL2

External MOSFET Gate Drive Output for Auxiliary Controller 2. DL2 swings between VDDC and PGND

with 400mA (typ) drive current. Connect DL2 to the gate of the external switching N-channel MOSFET

for auxiliary controller 2.

20

DL3

External MOSFET Gate Drive Output for Auxiliary Controller 3. DL3 swings between VDDC and PGND

with 400mA (typ) drive current. Connect DL3 to the gate of the external switching N-channel MOSFET

for auxiliary controller 3.

21

COMP3

Compensation for Auxiliary Controller 3. Output of auxiliary controller 3 transconductance error

amplifier. Connect a series resistor and capacitor from COMP3 to GND to compensate the auxiliary

controller 3 control loop (see Compensation Design).

22

FB3

Feedback Input for Auxiliary Controller 3. Connect a feedback resistive voltage-divider from the

output of auxiliary controller 3 to FB3 to set the output voltage. Regulation voltage is V

REF

(1.25V).

23

DCON3

Maximum Duty Cycle Control Input for Auxiliary Controller 3. Connect DCON3 to VL to set the default

maximum duty cycle. Connect a resistive voltage-divider from REF to DCON3 to set the maximum

duty cycle between 40% and 90%. Pull DCON3 below 300mV to turn the controller off.

24

ONC

Core Converter Enable Input. High level turns on the core converter. Connect ONC to VL to

automatically start the core converter.

25

PGND

Power Ground. Sources of internal N-channel MOSFET power switches. Connect PGND to GND as

close to the IC as possible.

26

LXC

Core Power Switching Node. Drains of the internal P- and N-channel MOSFET switches for the core

converter.

27

VDDC

Core DC-DC Converter Power Input. VDDC is connected to the source of the internal P-channel

MOSFET power switch for the core converter. VDDC is limited to 5.5V. For battery voltages greater

than 5.5V, connect VDDC to the main output. Bypass VDDC to PGND with a 1

µF or greater ceramic

capacitor.

28

VL

Internal Low-Voltage Bypass. The internal circuitry is powered from VL. An internal linear regulator

powers VL from VDDM when VDDC is less than 2.4V. When VDDC is greater than 2.4V, an internal

switch connects VL to VDDC. Bypass VL to GND with a 1.0

µF or greater ceramic capacitor.

29

COMPC

Compensation for Core Converter. Output of core transconductance error amplifier. Connect a series

resistor and capacitor to GND to compensate the core control loop (see Compensation Design).

30

FBC

Core DC-DC Converter Feedback Input. Connect a feedback resistive voltage-divider from the core

output to FBC to set the output voltage. Regulation voltage is V

REF

(1.25V).

31

REF

1.25V Reference Output. Bypass REF to GND with a 0.1

µF or greater ceramic capacitor.

32

GND

Analog Ground

Pin Description (continued)