2 calibration delay, 3 output edge synchronization, 4 power down feature – Rainbow Electronics ADC081000 User Manual

Page 26: 0 the digital outputs, 0 power considerations, 1 supply voltage, Figure 8. non-spiking power supply, Applications information

Applications Information

(Continued)

5.2 Calibration Delay

The CalDly input (pin 127) is used to select one of two delay

times after the application of power to the start of calibration,

as described in Section 1.1. The calibration delay values

allow the power supply to come up and stabilize before

calibration takes place. With no delay or insufficient delay,

calibration would begin before the power supply is stabilized

at its operating value and result in non-optimal calibration

coefficients. If the PD pin is high upon power-up, the calibra-

tion delay counter will be disabled until the PD pin is brought

low. Therefore, holding the PD pin high during power up will

further delay the start of the power-up calibration cycle. The

best setting of the CalDly pin depends upon the power-on

settling time of the power supply.

5.3 Output Edge Synchronization

DCLK signals are available to help latch the converter output

data into external circuitry. The output data can be synchro-

nized with either edge of these clock signals. That is, the

output data transition can be set to occur with either the

rising edge or the falling edge of the DCLK signal, so that

either edge of that clock signal can be used to latch the

output data into the receiving circuit.

When the OutEdge pin is high, the output data is synchro-

nized with (changes with) the rising edge of DCLK+. When

OutEdge is low, the output data is synchronized with the

falling edge of DCLK+.

At the very high speeds of which the ADC081000 is capable,

slight differences in the lengths of the clock and data lines

can mean the difference between successful and erroneous

data capture. The OutEdge pin is used to capture data on

the DCLK edge that best suits the application circuit and

layout.

5.4 Power Down Feature

The Power Down (PD) pin, when high, puts the ADC081000

into a low power mode where power consumption is greatly

reduced.

The digital output pins retain the last conversion output code

when the clock is stopped, but are in a high impedance state

when the PD pin is high. However, upon return to normal

operation (re-establishment of the clock and/or lowering of

the PD pin), the pipeline will contain meaningless informa-

tion and must be flushed.

If the PD input is brought high while a calibration is running,

the device will not go into power down until the calibration

sequence is complete. However, if power is applied and PD

is already high, the device will not begin the calibration

sequence until the PD input goes low. If a manual calibration

is requested while the device is powered down, the calibra-

tion will not begin at all. That is, the manual calibration input

is completely ignored in the power down state.

6.0 THE DIGITAL OUTPUTS

The ADC081000 demultiplexes its output data onto two

LVDS output buses.

The results of successive conversions started on the odd

falling edges of the CLK+ pin are available on one of the two

LVDS buses, while the results of conversions started on the

even falling edges of the CLK+ pin are available on the other

LVDS bus. This means that the word rate at each LVDS bus

is 1/2 the ADC081000 clock rate and the two buses must be

interleaved to obtain the entire 1 GSPS conversion result.

Since the minimum recommended clock rate for this device

is 200 MSPS, the effective sample rate can be reduced to as

low as 100 MSPS by using the results available on just one

of the the two LVDS buses and a 200 MHz input clock,

decimating the 200 MSPS data by two.

There is one LVDS clock pair available for use to latch the

LVDS outputs on both buses. Whether the data is sent at the

rising or falling edge of DCLK+ is determined by the sense of

the OutEdge pin, as described in Section 5.3.

The OutV pin is used to set the LVDS differential output

levels. See Section 1.5.

The output format is Offset Binary. Accordingly, a full-scale

input level with V

IN

+ positive with respect to V

IN

− will pro-

duce an output code of all ones, a full-scale input level with

V

IN

− positive with respect to V

IN

+ will produce an output

code of all zeros and when V

IN

+ and V

IN

− are equal, the

output code will vary between 127 and 128.

7.0 POWER CONSIDERATIONS

A/D converters draw sufficient transient current to corrupt

their own power supplies if not adequately bypassed. A 33

µF capacitor should be placed within an inch (2.5 cm) of the

A/D converter power pins. A 0.1 µF capacitor should be

placed as close as possible to each V

A

pin, preferably within

one-half centimeter. Leadless chip capacitors are preferred

because they have low lead inductance. Having power and

ground planes in adjacent layers of the PC Board will provide

the best supply bypass capacitance in terms of low ESL.

The V

A

and V

DR

supply pins should be isolated from each

other to prevent any digital noise from being coupled into the

analog portions of the ADC. A ferrite choke, such as the JW

Miller FB20009-3B, is recommended between these supply

lines when a common source is used for them.

As is the case with all high speed converters, the

ADC081000 should be assumed to have little power supply

noise rejection. Any power supply used for digital circuity in a

system where a lot of digital power is being consumed

should not be used to supply power to the ADC081000. The

ADC supplies should be the same supply used for other

analog circuitry, if not a dedicated supply.

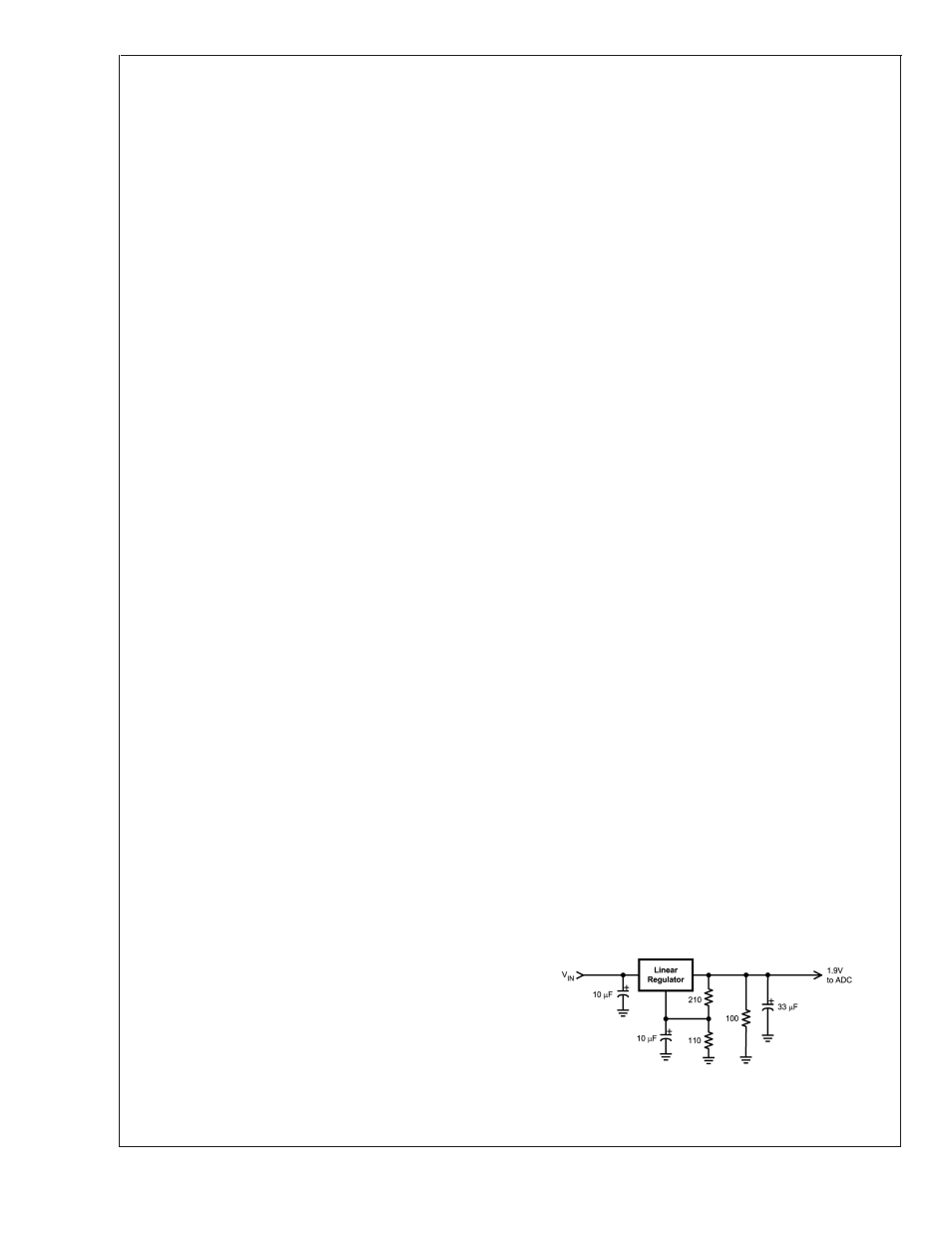

7.1 Supply Voltage

The ADC081000 is specified to operate with a supply voltage

of 1.9V

±

0.1V. It is very important to note that, while this

device will function with slightly higher supply voltages,

these higher supply voltages may reduce product lifetime.

No pin should ever have a voltage on it that is in excess of

the supply voltage or below ground by more than 150 mV,

not even on a transient basis. This can be a problem upon

application of power and power shut-down. Be sure that the

supplies to circuits driving any of the input pins, analog or

digital, do not come up any faster than does the voltage at

the ADC081000 power pins.

20068154

FIGURE 8. Non-Spiking Power Supply

ADC081000

www.national.com

26