Max8730 low-cost battery charger, Table 4. recommended inductors, Table 5. recommended input capacitors – Rainbow Electronics MAX8730 User Manual

Page 25

MAX8730

Low-Cost Battery Charger

______________________________________________________________________________________

25

where

θ

JA

is the thermal resistance of the package (in

°C/W), T

J_MAX

is the maximum junction temperature of

the diode, T

A_MAX

is the maximum ambient tempera-

ture of the system, and V

F

is the forward voltage of the

Schottky diode.

The Schottky size and cost can be reduced by utilizing

the MAX8730 foldback function. See the Trickle Charge

section for more information.

Select the Schottky diode to minimize the battery leakage

current when the charger is shut down.

Inductor Selection

The MAX8730 uses a fixed inductor current ripple

architecture to minimize the inductance. The charge

current, ripple, and operating frequency (off-time)

affects inductor selection. For a good trade-off of

inductor size and efficiency, choose the inductance

according to the following equation:

where k

OFF

is the off-time constant (5.6V x µs typically).

Higher inductance values decrease the RMS current at

the cost of inductor size.

Inductor L1 must have a saturation current rating of at

least the maximum charge current plus 1/2 of the ripple

current (

∆I

L

):

I

SAT

= I

CHG

+ (1/2)

∆I

L

The ripple current is determined by:

The ripple current is only dependent on inductance

value and is independent of input and output voltage.

See the Ripple Current vs. V

BATT

graph in the Typical

Operating Characteristics.

See Table 4 for suggestions about inductor selection.

Input Capacitor Selection

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents.

Ceramic capacitors are preferred due to their resilience

to power-up surge currents:

at 50% duty cycle.

The input capacitors should be sized so that the tem-

perature rise due to ripple current in continuous con-

duction does not exceed about 10°C. The maximum

ripple current occurs at 50% duty factor or V

SRC

= 2 x

V

BATT

, which equates to 0.5 x I

CHG

. If the application

of interest does not achieve the maximum value, size

the input capacitors according to the worst-case condi-

tions. See Table 5 for suggestions about input capaci-

tor selection.

I

I

V

V

V

V

I

RMS

CHG

BATT

SRC

BATT

SRC

CHG

=

−

(

)

=

2

∆I

k

L

L

OFF

=

L

k

x I

OFF

CHG

.

=

0 4

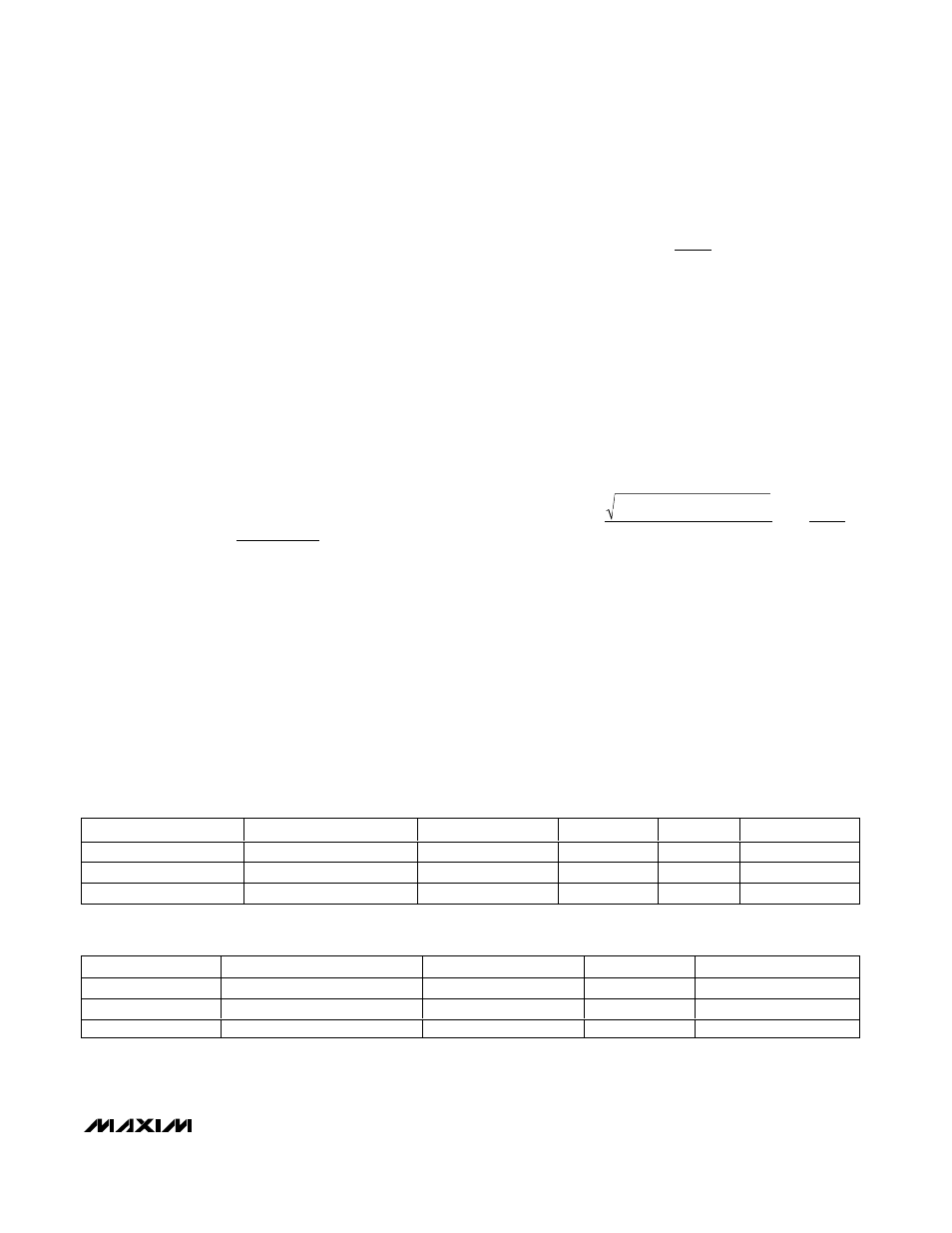

Table

4. Recommended Inductors

APPLICATION (A)

INDUCTOR

SIZE (mm)

L (µH)

I

SAT

(A)

R

L

(m

Ω

Ω

Ω

Ω)

2.5

CDRH6D38

8.3 x 8.3 x 3

3.3

3.5

20

2.5

CDRH8D28

7 x 7 x 4

4.7

3.4

24.7

3.5

CDRH8D38

8.3 x 8.3 x 4

3.5

4.4

24

Table

5. Recommended Input Capacitors

APPLICATION (A)

INPUT CAPACITOR

CAPACITANCE( µF)

VOLTS (V)

RMS AT 10°C (A)

< 3

GMK316F47S2G

4.7

35

1.8

< 4

GMK325F106ZH

4.7

35

2.4

< 4

TMK325BJ475MN

10

25

2.5