Fault management and reporting – Rainbow Electronics MAX34441 User Manual

Page 21

PMBus 5-Channel Power-Supply Manager

and Intelligent Fan Controller

MAX34441

21

The following example demonstrates how the host can

send and retrieve values from the device. Table 4 shows

the coefficients used in the following parameters.

If a host wants to set the device to change the power-

supply output voltage to 3.465V (or 3465mV), the cor-

responding VOUT_MARGIN_HIGH value is:

Y = (1 x 3465 + 0) x 10

0

= 3465 (decimal) = 0D89h (hex)

Conversely, if the host received a value of 0D89h on a

READ_VOUT command, this is equivalent to:

X = (1/1) x (0D89h x 10

-(-0)

- 0) = 3465mV = 3.465V

Power supplies and power converters generally have

no way of knowing how their outputs are connected to

ground. Within the power supply, all output voltages are

most commonly treated as positive. Accordingly, all out-

put voltages and output voltage-related parameters of

PMBus devices are commanded and reported as posi-

tive values. It is up to the system to know that a particular

output is negative if that is of interest to the system. All

output-voltage-related commands use 2 data bytes.

Fault Management and Reporting

For reporting faults/warnings to the host on a real-time

basis, the device asserts the open-drain ALERT pin (if

enabled in MFR_MODE) and sets the appropriate bit in

the various status registers. On recognition of the ALERT

assertion, the host or system manager is expected to poll

the I

2

C bus to determine the device asserting ALERT.

The host sends the SMBus ARA (0001 100). The device

ACKs the SMBus ARA, transmits its slave address, and

deasserts ALERT. The system controller then communi-

cates with PMBus commands to retrieve the fault/warn-

ing status information from the device.

See the individual command sections for more details.

Faults and warnings that are latched in the status regis-

ters are cleared when any one of the following conditions

occurs:

• A CLEAR_FAULTS command is received.

• The RST pin is toggled.

• Bias power to the device is removed and then reapplied.

One or more latched-off power supplies is only restarted

when one of the following occurs:

• The output is commanded through the CONTROL

pin, the OPERATION command, to turn off and then

turn back on.

• The RST pin is toggled.

• Bias power to the device is removed and then reapplied.

A power supply is not allowed to turn on if any faults the

supply responds to are detected. Only after the faults

clear is the power supply allowed to turn on. When global

supplies are being sequenced on, a fault on any of the

supplies keeps all supplies from being turned on.

A system-wide power-up (OPERATION command is

received to turn the supplies on when PAGE is 255 or the

CONTROL pin is toggled to turn on the supplies) allows

all enabled power supplies to power-up. If any faults are

detected once the supplies start to turn on, the response

of MFR_FAULT_RESPONSE is performed.

The device responds to fault conditions accord-

ing to the manufacturer fault response command

(MFR_FAULT_RESPONSE). This command byte

determines how the device should respond to each

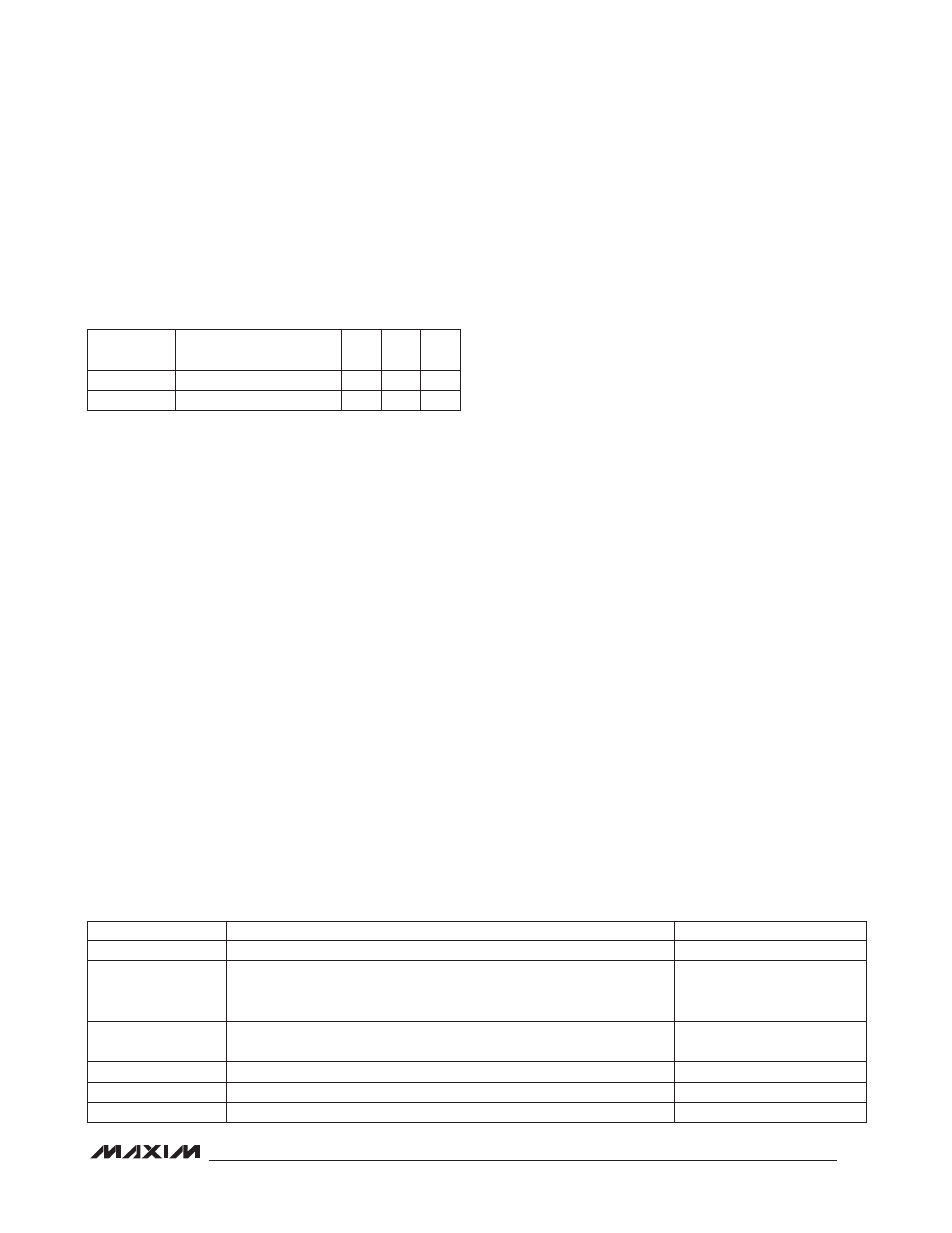

Table 4. Coefficients for DIRECT Format

Value

Table 5. Device Parametric Monitoring States

COMMAND

CODE

COMMAND NAME

m

b

R

25h

VOUT_MARGIN_HIGH

1

0

0

8Bh

READ_VOUT

1

0

0

PARAMETER

REQUIRED CONDITIONS FOR ACTIVE MONITORING

ACTION DURING A FAULT

Overvoltage

Power Supply Enabled (TON_MAX_FAULT_LIMIT ≠ 0000h)

Continue Monitoring

Undervoltage

•

Power Supply Enabled (TON_MAX_FAULT_LIMIT ≠ 0000h)

•

PSEN Output is Active

•

Channel’s VOUT > POWER_GOOD_ON

Stop Monitoring While the

Power Supply is Off

Overcurrent

•

Power Supply Enabled (TON_MAX_FAULT_LIMIT ≠ 0000h)

•

Current Monitoring Enabled (IOUT_OC_FAULT_LIMIT ≠ 0000h)

Continue Monitoring

Power-Up Time

Power Supply Enabled (TON_MAX_FAULT_LIMIT ≠ 0000h)

Monitor Only During Power-On

Overtemperature

Temp Sensor Enabled (ENABLE in MFR_TEMP_SENSOR_CONFIG = 1)

Continue Monitoring

Fan Speed

Fan Enabled (Bit 7 in FAN_CONFIG_1_2 = 1)

Continue Monitoring