Tests, Testing wrenches – Snap-On DTT User Manual

Page 14

Tests

Testing Wrenches

• To avoid damage, be sure the DTT model being used

is capable of handling the torque being applied.

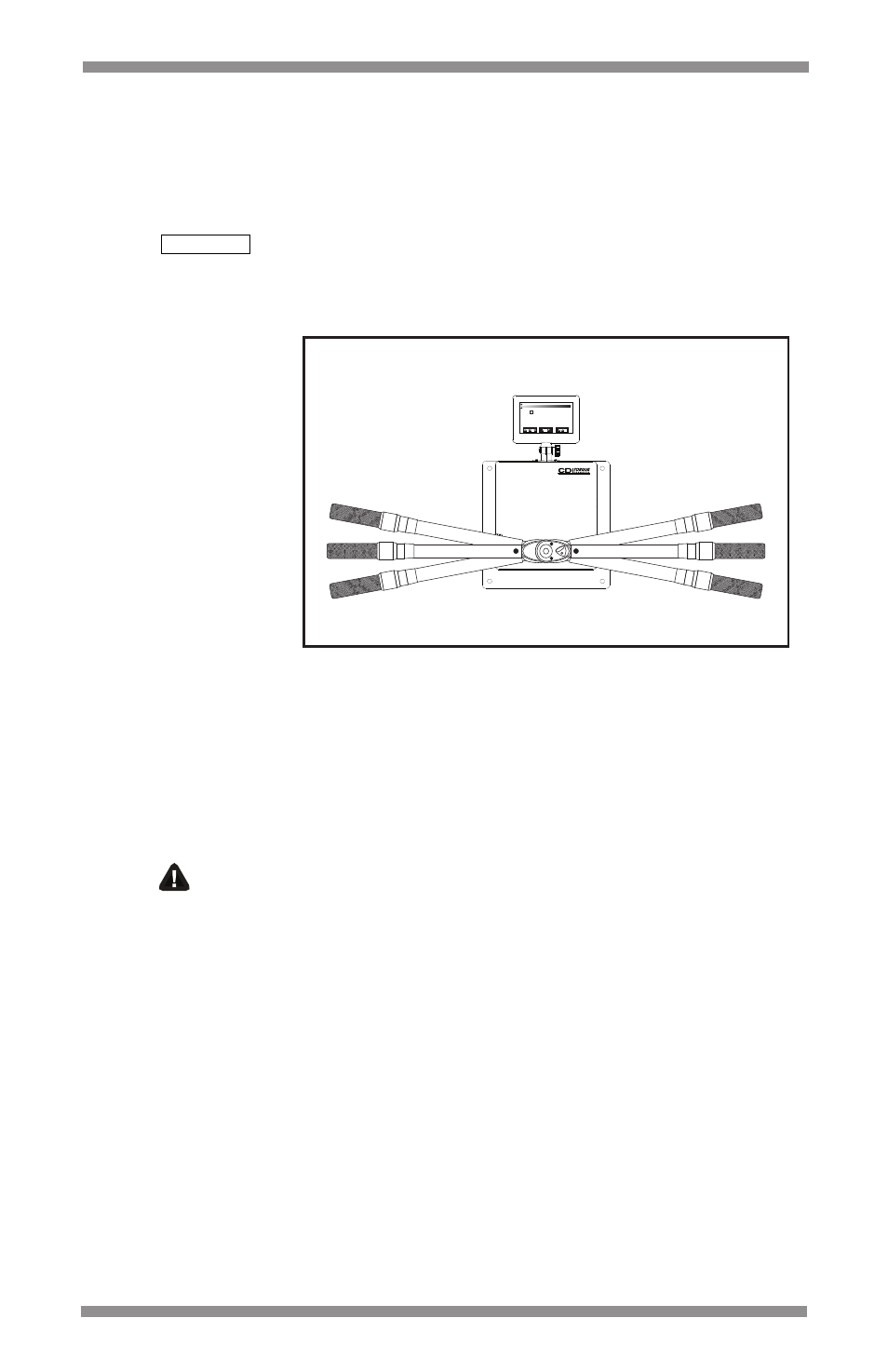

• Always position a torque wrench within 15° of

perpendicular to the display housing (Figure 5).

Testing Wrenches

1. Prepare tester for use. For additional information

refer to TESTER SETUP.

NOTE: DTT will ZEROTARE automatically when power

switch is turned ON.

2. In the MAIN MENU screen, select TEST.

NOTE: The operator can return to the MAIN MENU

at any step during this procedure by pressing

the MAIN button.

12

DTT Digital Torque Tester

IMPORTANT

3. In the SELECT WRENCH TYPE screen, select one

of the following options:

CLICK ADJUST

CLICK PRESET

DIAL / ELEC

SCREWDRIVER

Figure 5: Wrench Position, Perpendicular to Tester

2503-F-DTT

0.0O

TGT TORQUE: 250

FIRST PEAK

FT-LB

MAIN MENU

SETUP

STORE

DATA: 25

WARNING

Do not turn the power switch ON with a torque

instrument engaged to tester transducer.