Electronics FC User Manual

Page 3

3

1. PRODUCT DESCRIPTION

The Model FC Shot Flow Controller will measure and control the flow rate of steel shot passing

through a special, normally-closed, magnetic valve called a MagnaValve. A digital display is pro-

vided for indications of shot flow rate. A 0-10Vdc output signal, representing flow rate, is available

for remote indication or strip-chart recording. High and low alarms are set to bracket the requested

shot flow rate. The alarm bandwidth is adjustable from the front panel. Either local (front panel), or

remote (0-10Vdc) set point commands may be used.

2. THEORY OF OPERATION

The desired flow rate command, or “set point”, is compared to the actual flow rate and a power sig-

nal is sent to the MagnaValve to achieve desired flow rate. If the desired flow rate is not achieved

within an adjustable time period, then a high/low alarm relay will be triggered. This output signal may

be used to inhibit further machine operations and signal the operator. The FC Controller is used with

a MagnaValve that has a built-in flow rate sensor. This MagnaValve incorporates a preamplifier cir-

cuit that provides a 0-5Vdc output signal back to the FC Controller.

3. PRELIMINARY ADJUSTMENTS

For location of adjustments see (Figure-Item) as noted.

a. Apply power to unit.

b. The display should read 00 during a no-flow condition. Check the signal input at Terminals 17

& 18 for the flow sensor input from the MagnaValve. Confirm 0Vdc at the no-flow condition. If

the input signal is 0Vdc but the display does not show “00”, adjust the “ZERO” trimpot until

“00” appears on the display

c. For automatic machine cycle, place the “Mode” switch to the left for the ready mode (1-11).

When a 115VAC "Enable" signal is received, the ENABLE LED indicator (1-2) on the front

panel will light and activate the valve output. The red VALVE (1-3) LED will blink at 8-Hertz

(8 times per second). Adjust the flow rate SETPOINT knob (1-9) to desired flow rate. The

display (1-4) is usually scaled in pounds/minute, but may be scaled in Kg/minute.

d. Adjust the ALARM BAND (2-7), typically 10% of full scale by pushing the DISPLAY SWITCH

(1-10) to the left to exhibit the alarm bandwidth in the display. The alarm bandwidth is +/- of

this value and it follows the set point command.

e. Adjust the ALARM DELAY time (2-6) from 0-10 seconds. A typical setting is 5 seconds.

4. FLOW RATE CALIBRATION

Calibration of the display range may be required. The standard factory setting is 20.0-pounds/minute

full scale to match the model 578 MagnaValve. Other full-scale values may be used with different

MagnaValves.

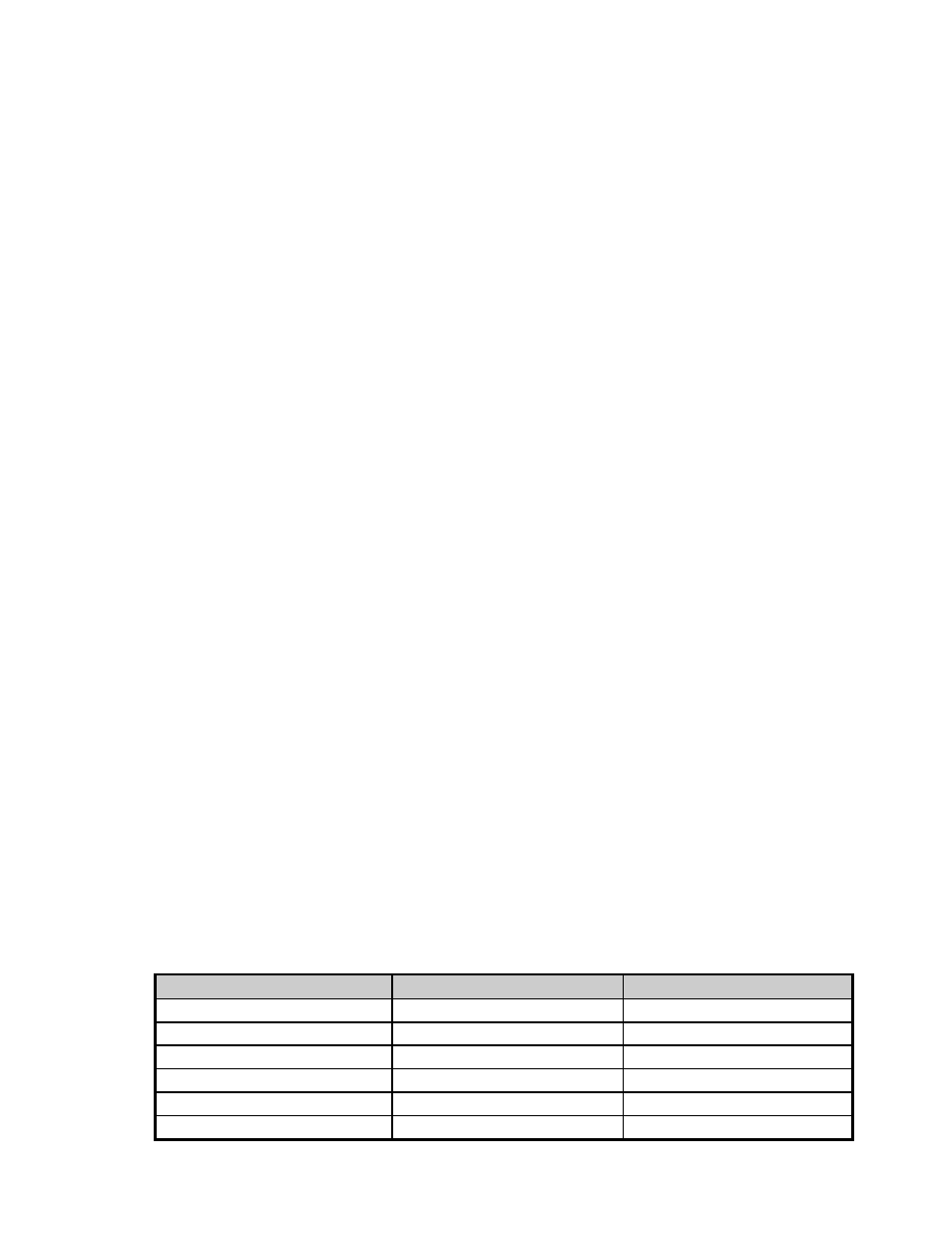

MagnaValve Model

Maximum Flow Rate

FC Display Full Scale

477 or 577

2 pounds/minute

2.00

478 or 578

20 pounds/minute

20.0

479 or 579

100 pounds/minute

100.0

480 or 580

200 pounds/minute

200

490 or 590

300 pounds/minute

300

VLP+ (with sensor option)

1000 pounds/minute

1000