Electric drive motor selection – Grain Systems Unload Augers PNEG-1555 User Manual

Page 26

26 PNEG-1555 8" Commercial Vertical Drive Unit - Dual Drive

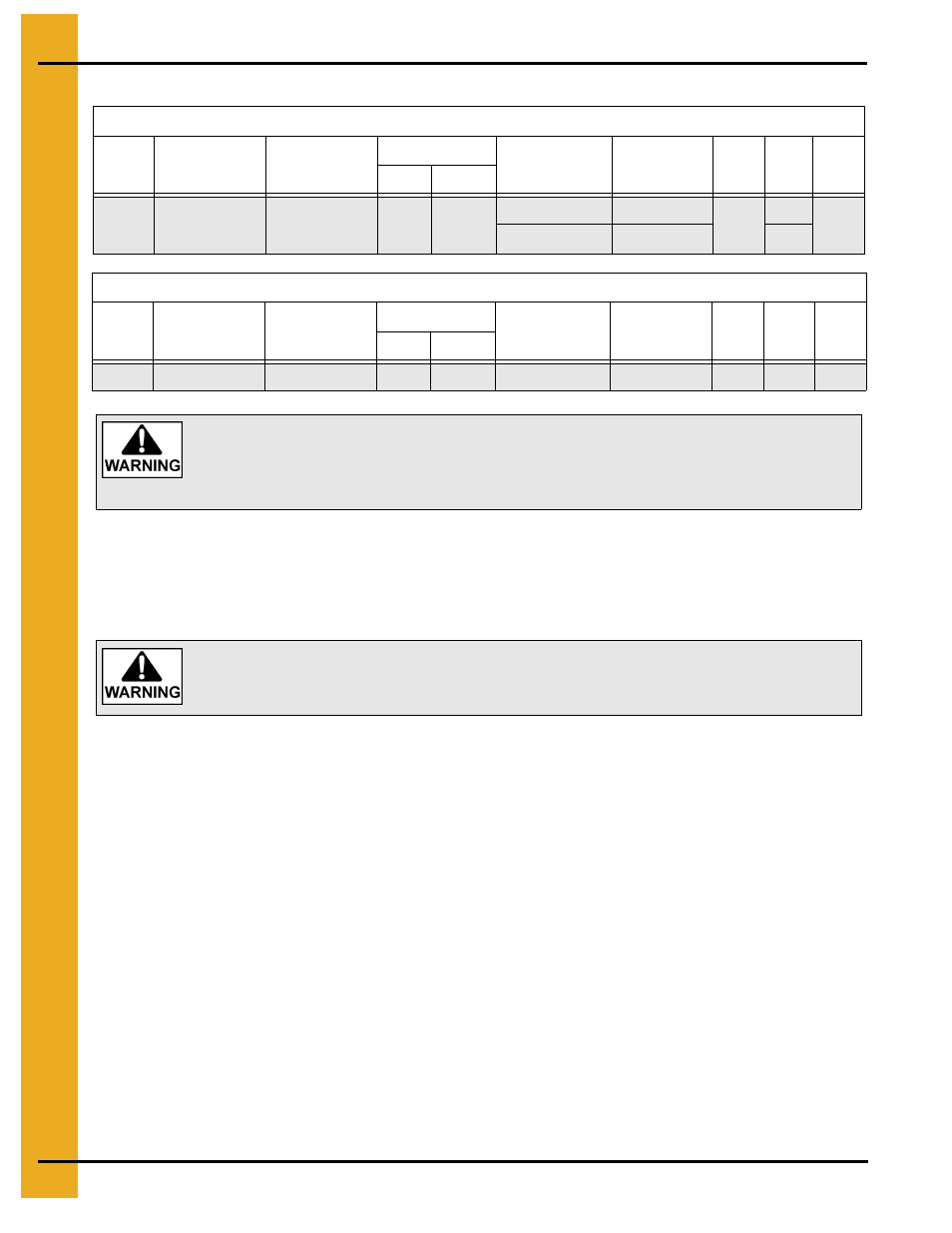

5. Electric Drive Motor Selection

Belt Section

4. A magnetic starter should be used for the operator’s protection and for the protection of the motor.

This is to protect the operator against accidental restart caused by power interruption, conductor

fault, low voltage, circuit interruption or motor overload. Therefore, the motor must be restarted

manually. If using a motor with built-in thermal overload protection, make sure this type of motor

has a manual reset.

Horizontal Drive

Auger

Part #

Motor Sheave

Size

Flight Sheave

NEMA Motor

Frame

Motor HP

Belt

Size

Belt

Qty

Belt

Type

Size

RPM

8"

MHC00487

3-1/2"

15"

409

182T and 184T

3-5 HP

71

2

BX

213T and 215T

7-1/2 - 10 HP

3

Vertical Drive

Auger

Part #

Motor Sheave

Size

Flight Sheave

NEMA Motor

Frame

Motor HP

Belt

Size

Belt

Qty

Belt

Type

Size

RPM

8"

GK1346

5"

15"

584

184T

5 HP

57

2

B

1750 RPM electric motors and controls shall be installed by a qualified

electrician, and must meet the standards set by the National Electrical Code and

all local and state codes. Reset and motor starting controls shall be located

where the operator has unrestricted access to the controls.

Disconnect and lock out power before resetting motor overloads. Make certain

electric motors are grounded.