Rough Country 525.20 User Manual

Page 3

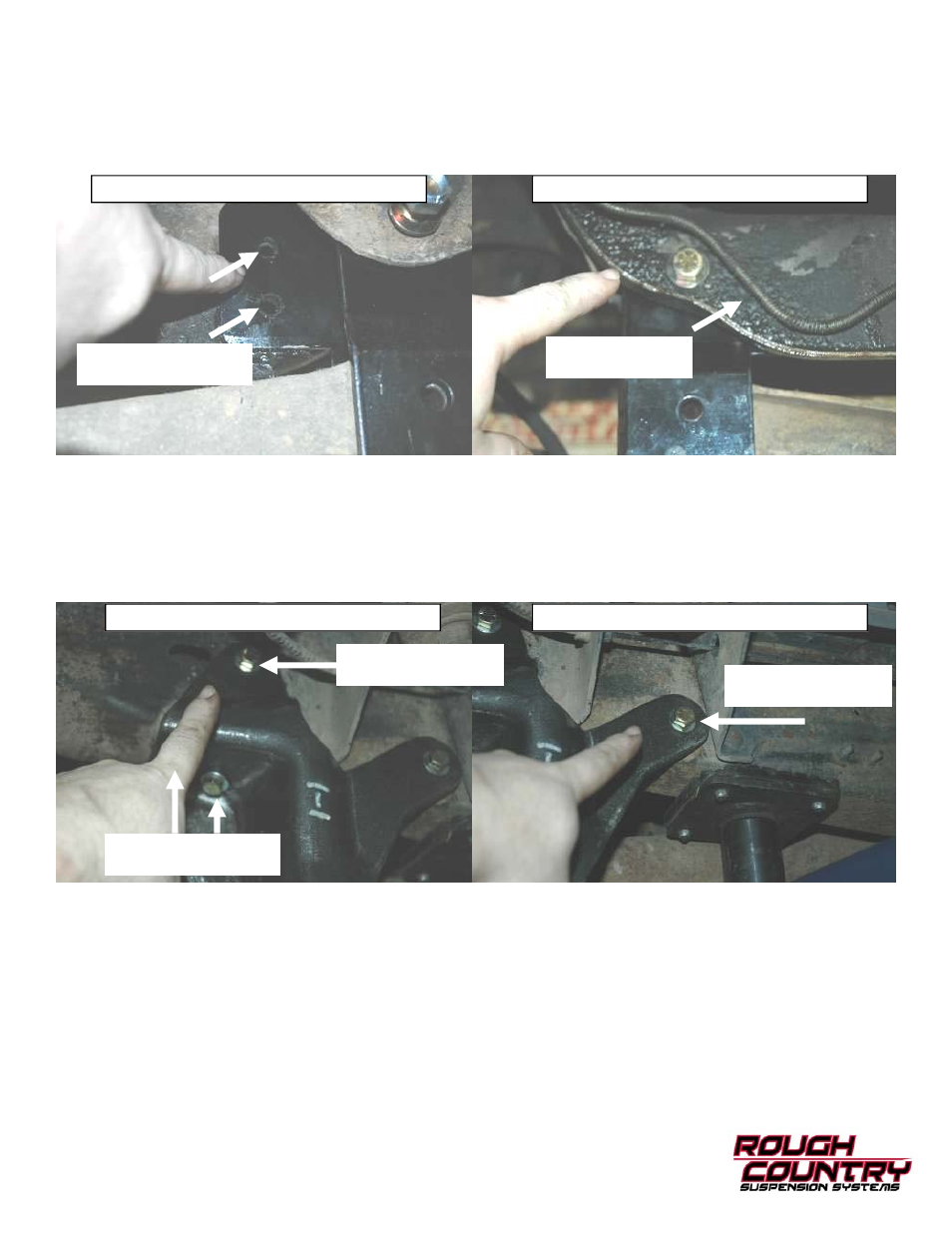

12. Detach the pivot bracket from the passengers side cross member. Using 21mm socket and 22mm wrench install the

new axle pivot bracket for the passengers side. Attach bracket to cross member with furnished 9/16” x 1” bolt, wash-

ers, and locknuts. Torque to 100 ft. lbs. IMPORTANT Be sure that the axle pivots are vertically aligned. Drill two

7/16” holes through the cross member and the new bracket. Using a 16mm socket, and a 17mm wrench install the

7/16” bolts, washers, and lock nuts. Reinstall the stock axle bolt through the appropriate hole 4” for the top hole, and

6” for the bottom hole. Torque to 60-75 ft. lbs.

13. Using a 16mm socket, and a 17mm wrench, the new radius arm lowering brackets are installed with furnished 7/16"

bolts, locknuts and flat washers. The factory nylon radius arm bushing rings, mounted directly against the rear face

of the stock stamped steel radius arm brackets, are not reused. The replacement brackets design allows you to dis-

card these pieces that are prone to fail. On 1980 and some 1981 models, all but one bracket-to-frame hole must be

drilled. Match the rear hole of the new bracket to the rear frame hole on the bottom of rail. Drill all other holes. Be

wary of wiring/hoses routed inside of the frame rails. Inspect radius arm bushings for cracks, dry rot and deformities.

Torque radius arm bushing nuts to 80-100 ft. lbs.

14. Install new coil spring. When lowering the axles for spring installation, take care not to overextend the factory rubber

brake hoses. Using a 13mm socket reinstall the spring clip and torque to 13-18 ft. lbs. Using a 1 1/8” wrench reinstall

lower nut and torque to 50-70 ft. lbs. On some vehicles factory equipped with dual front shocks, keep the bottom of

the coil pulled as far rearward as possible to gain clearance between coil and front shock.

15. Repeat procedure on passenger side

16. Install Pitman Arm per their separate instructions. Attach drag link to pitman arm nut and install cotter pin.

17. On vehicles factory equipped with front anti-sway bar, install relocating hardware (purchased separately, see SEPA-

RATE INSTRUCTIONS). This is also a good opportunity to replace worn factory rubber bushings.

18. Reinstall wheels and tires.

19. Remove jack stands and lower vehicle to the ground. If vehicle is equipped with a front sway bar, relocation brackets

are required if you are installing a 6” lift. Install these now per separate instructions.

20. Check all fasteners to be sure they are torqued properly.

21. Install warning to driver sticker on sun visor.

Drill 7/16” Holes Here

For Bracket Installation

Passenger Side Axle Bracket— View From Rear

Passenger Side Axle Bracket—View From Front

When Drilling Show

Care to Miss Line

Radius Arm Bracket Installation

Radius Arm Bracket Installation

Using these factory

holes to secure bracket

Drill 7/16” Hole Here

For Bracket Installation

Drill 7/16” Hole Here

For Bracket Installation