Structures – Milton CAT 345D L User Manual

Page 9

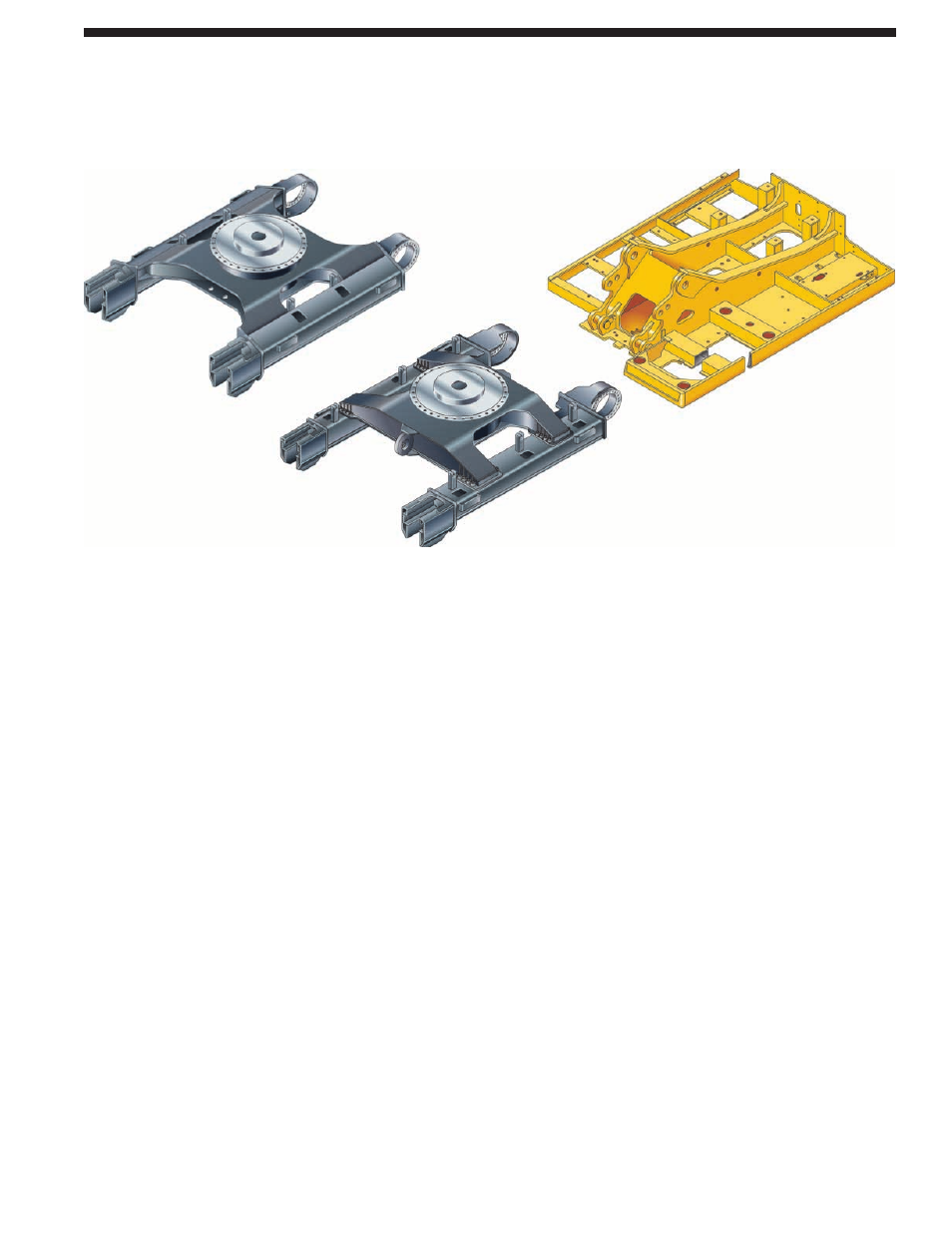

Carbody. The 345D L has three

undercarriage options to meet regional

transportation requirements and

application needs.

•

Fixed gauge for narrow transport

and weight sensitive areas.

•

Variable gauge for increased

track and ground clearance and

over-side lift.

•

Wide variable gauge, provided as

an attachment to the variable gauge

machine, provides a significant

increase in over-side lift with the

capability for handling larger buckets.

The carbody utilizes a columnless

design that allows the swing bearing

to be directly mounted on the top plate

for excellent rigidity and strength.

Upper Frame. The rugged main frame

is designed for maximum durability.

Robot welding is used for consistent,

high-quality welds. The main channels

are box sections connected by a large

diameter tube in the boom foot area to

improve rigidity and strength. The outer

frame utilizes curved side rails for rigidity

against bending and torsional loads.

Counterweights. The 345D L has

several counterweight options to best

match the machine to your application.

Counterweight removal device is

available for the 7.6 mt (16,760 lb)

and 8.7 mt (19,180 lb) counterweights

to facilitate transport when needed.

Track Roller Frame. Fixed Gauge

Undercarriage

•

Uses a press-formed, pentagonal

section for the track frame that is

robot-welded for weld consistency

and quality. The track frame has

been designed so that the top of

the track frame has a steep angle

to help prevent accumulation

of mud and debris.

Variable Gauge Undercarriage

•

The track roller frame is made of

thick steel plate that is bent into a

U shape and welded to the bottom

plate to create a box structure.

The box structure design increases

rigidity and impact resistance.

9

Structures

The 345D L structural components are the backbone of the machine’s durability.