VEGA VEGAPULS 62 (≥ 2.0.0 - ≥ 4.0.0) 4 … 20 mA_HART - two-wire, approval according to LPR radio standard User Manual

Page 60

The below tables show typical examples of application-relevant

measurement errors with liquids. The measurement errors are

differentiated according to the following:

l

Constant level

l

Filling

l

Emptying

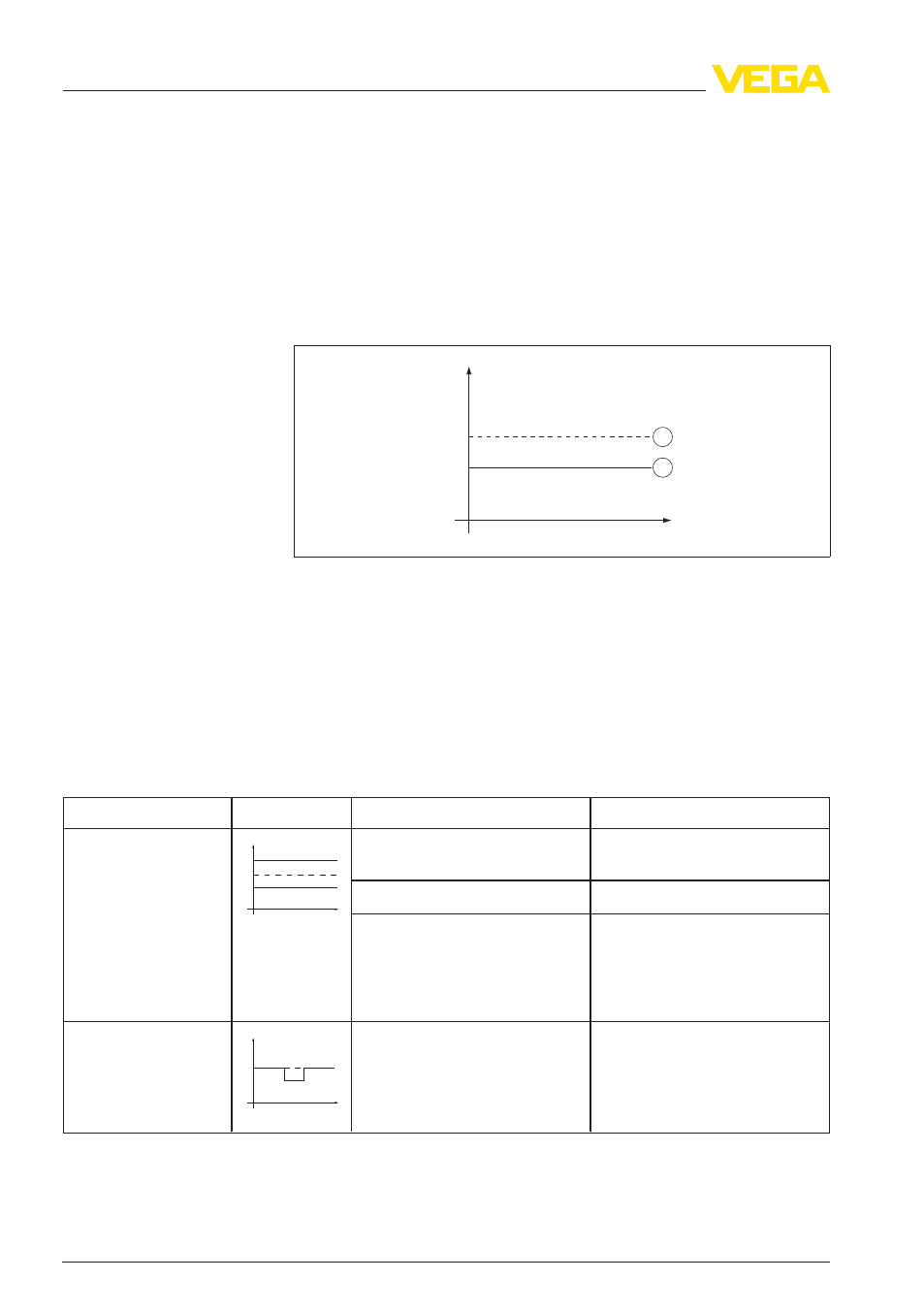

The images in column "Error pattern" show the actual level with a

broken line and the level displayed by the sensor as a continuous line.

1

2

L

e

ve

l

time

0

1

Real level

2

Level displayed by the sensor

Instructions:

l

Wherever the sensor displays a constant value, the reason could

also be the fault setting of the current output to "Hold value"

l

In case of a too low level indication, the reason could be a line

resistance that is too high

Measurement error with constant level

Fault description

Error pattern

Cause

Rectification

1. Measured value

shows a too low or too

high level

Level

time

0

l Min./max. adjustment not cor-

rect

l Adapt min./max. adjustment

l Linearization curve incorrect

l Adapt linearization curve

l Installation in a bypass tube or

standpipe, hence running time

error (small measurement er-

ror close to 100 %/large error

close to 0 %)

l Check parameter "Application"

with respect to vessel form,

adapt if necessary (bypass,

standpipe, diameter)

2. Measured value

jumps towards 0 %

Level

time

0

l Multiple echo (vessel top, pro-

duct surface) with amplitude

higher than the level echo

l Check parameter "Application",

in particular Vessel top, Pro-

duct type, Dished bottom, High

dielectric value and adapt if

necessary

Treatment of measure-

ment errors with liquids

60

VEGAPULS

62 • 4 … 20 mA/HART - two-wire, approval according to LPR radio standard

9 Diagnosis, Asset Management and service

41718

-EN

-120301