Conditioning – VEGA VEGAPULS 45 4 … 20 mA; HART compact sensor User Manual

Page 46

46

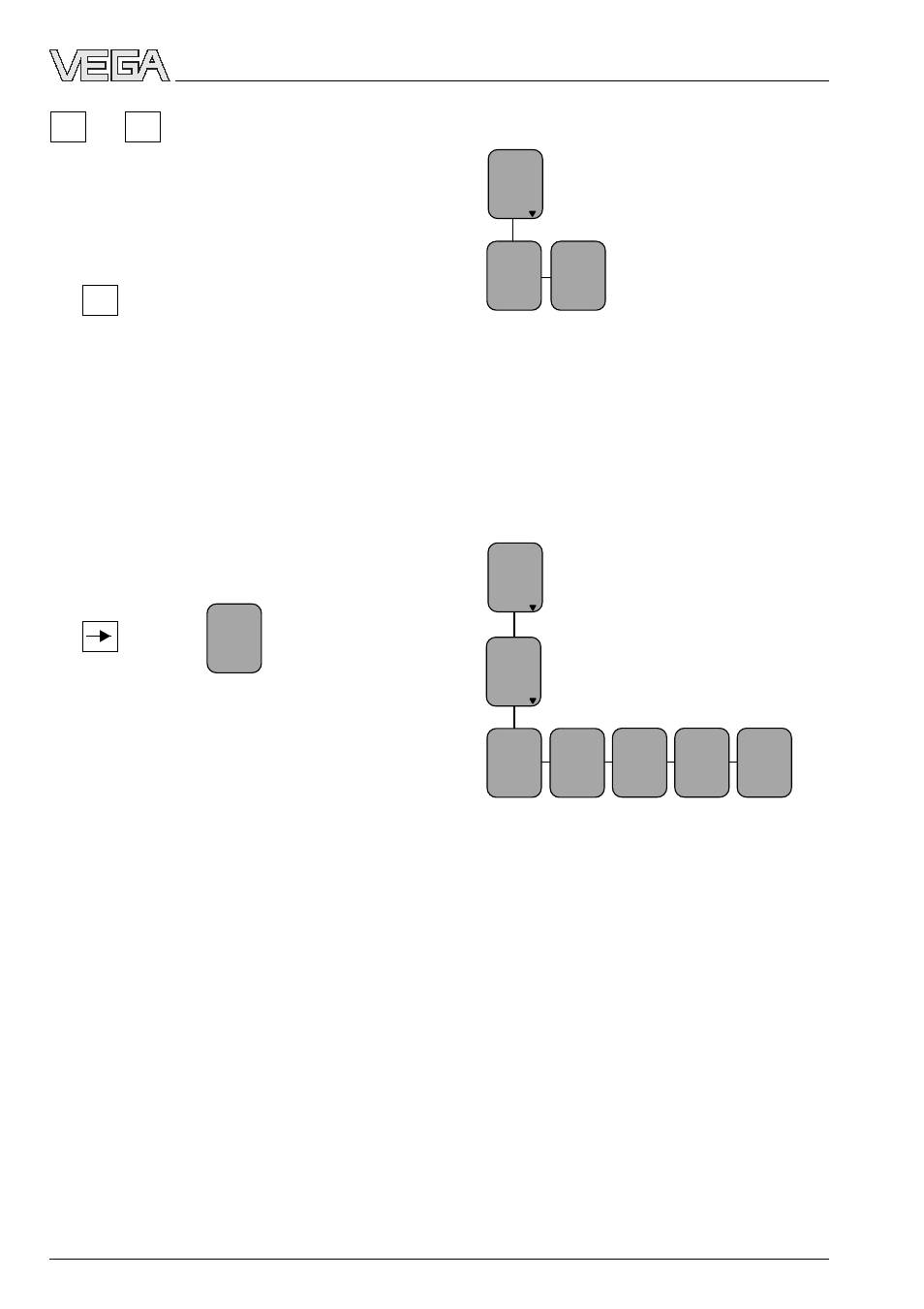

VEGAPULS 42, 44 and 45 – 4 … 20 mA

with

medium

Min.

adjust

at %

XXX.X

Max.

adjust

at %

XXX.X

Signal

condit

ioning

Scal

ing

0 %

corres

ponds

XXXX

100 %

corres

ponds

XXXX

Deci-

mal

point

888.8

prop.

to

Mass

Unit

Kg

Adjustment with medium

Fill the vessel e.g. to 10 % and enter 10 % in

the menu "

Min. adjust“ with the "+“ and "–“

keys. Then fill the vessel, e.g. to 80 % or

100 % and enter 80 % or 100 % in the menu

"

Max. adjust“ with the "+“ and "–“ keys.

4. Conditioning

Under the menu item "

Conditioning“, you

assign a product distance at 0 % and at 100

% filling. Then, you enter the parameter and

the physical unit as well as the decimal point.

Enter in the menu window "

0 % corresponds“

the numerical value of the 0 % filling. In the

example of the adjustment with the PC and

the adjustment software VVO, this would be

45 for 45 liters.

• Confirm with "

OK“.

With the "—>“ key you switch to the 100 %

menu. Enter here the numerical value of your

parameter corresponding to a 100 % filling.

In the example 1200 for 1200 liters.

With the "

+“ or "–“ key you can

assign a level distance (ex-

ample 5.85 m) to the previ-

ously adjusted percentage

value. If you do not know the

distance, you have to do a

sounding.

The adjusted product dis-

tance is written in the sensor

and the display stops flash-

ing.

You thereby adjusted the lower product dis-

tance as well as the percentage filling value

corresponding to the lower product distance.

Note:

For level detection outside the operating range,

the operating range must be corrected accord-

ingly in the menu "

Sensor optimisation/Operat-

ing range“.

OK

+

–

or

100.0%

at

m (d)

XX.XXX

(max. adjustment)

Now you make the max. adjustment (upper

product distance) (example: 100 % and

1.270 m product distance). First, enter the

percentage value and then the product dis-

tance corresponding to that percentage value.

Note:

The difference between the adjustment val-

ues of the lower product distance and the

upper product distance should be as big as

possible, preferably at 0 % and 100 %. If the

values are very close together, e.g. lower

product distance at 40 % (3.102 m) and

upper product distance at 45 % (3.331 m),

the measurement will be less accurate. A

characteristic curve is generated from the

two points. Even the smallest deviations

between actual product distance and en-

tered product distance will considerably

influence the slope of the characteristic

curve. If the adjustment points are too close

together, small errors inflate to considerably

larger ones when the 0 % or the 100 % value

is outputted.

Set-up