VEGA VEGAPULS 45 4 … 20 mA; HART compact sensor User Manual

Page 17

VEGAPULS 42, 44 and 45 – 4 … 20 mA

17

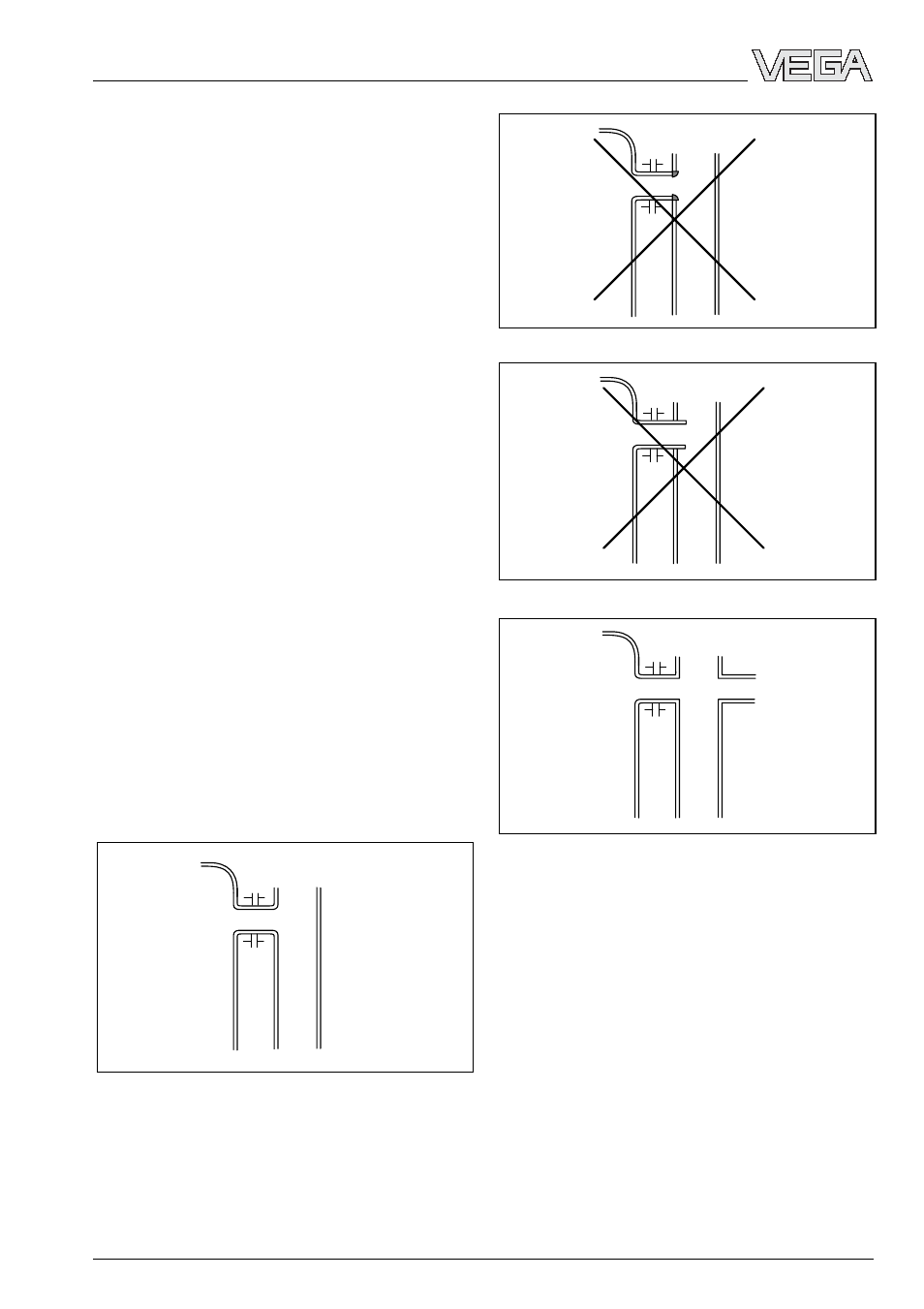

Welding beads too large

Tube connection protrudes

Additional connection in the bypass tube in one plane

Use of guide tubes

(VEGAPULS 44)

In case of very rough inner surfaces in exist-

ing bypass tubes (e.g. due to corrosion),

large connection openings as well as bypass

tubes with more than 100 mm inner diameter,

the use of a guide tube inside the existing

bypass tube is recommended. This reduces

the noise level and increases reliability con-

siderably. The flange of the guide tube can

be easily mounted as a sandwich flange

between vessel and sensor flange.

If enough liquid (300 … 800 mm) remains in

the blind lower end of the tube, the portion of

the signal that penetrates the liquid and re-

flects from the tube bottom is sufficiently

damped - the sensor can then easily distin-

guish it from the echo of the liquid surface. In

cases where there is not enough liquid at the

bottom of the tube, a deflector situated there

will carry out the same function. It deflects

signals that reach the tube bottom into the

standard connection opening.

Connections to the bypass tube

The connections to the bypass tubes must

be fashioned in such a way that only minimal

reflections are caused by the walls of the

connecting tubes. This is especially important

for the breather connection in the upper part

of the tube. Observe the following points:

• Use small openings for the connection.

• The diameter of the connecting tubes

should not exceed 1/3 of the bypass tube

diameter.

• The tube connections must not protrude

into the bypass tube.

• Large welding beads in the tubes should

be avoided.

• Additional connections to the bypass tube

must lie in the same plane as the upper

and lower vessel connection (above each

other or displaced by 180°).

Mounting and installation

Optimum connection to the bypass tube