Heat insulation, Emission cone and false echoes – VEGA VEGAPULS 56K User Manual

Page 12

12

VEGAPULS 56K

22915-EN-041227

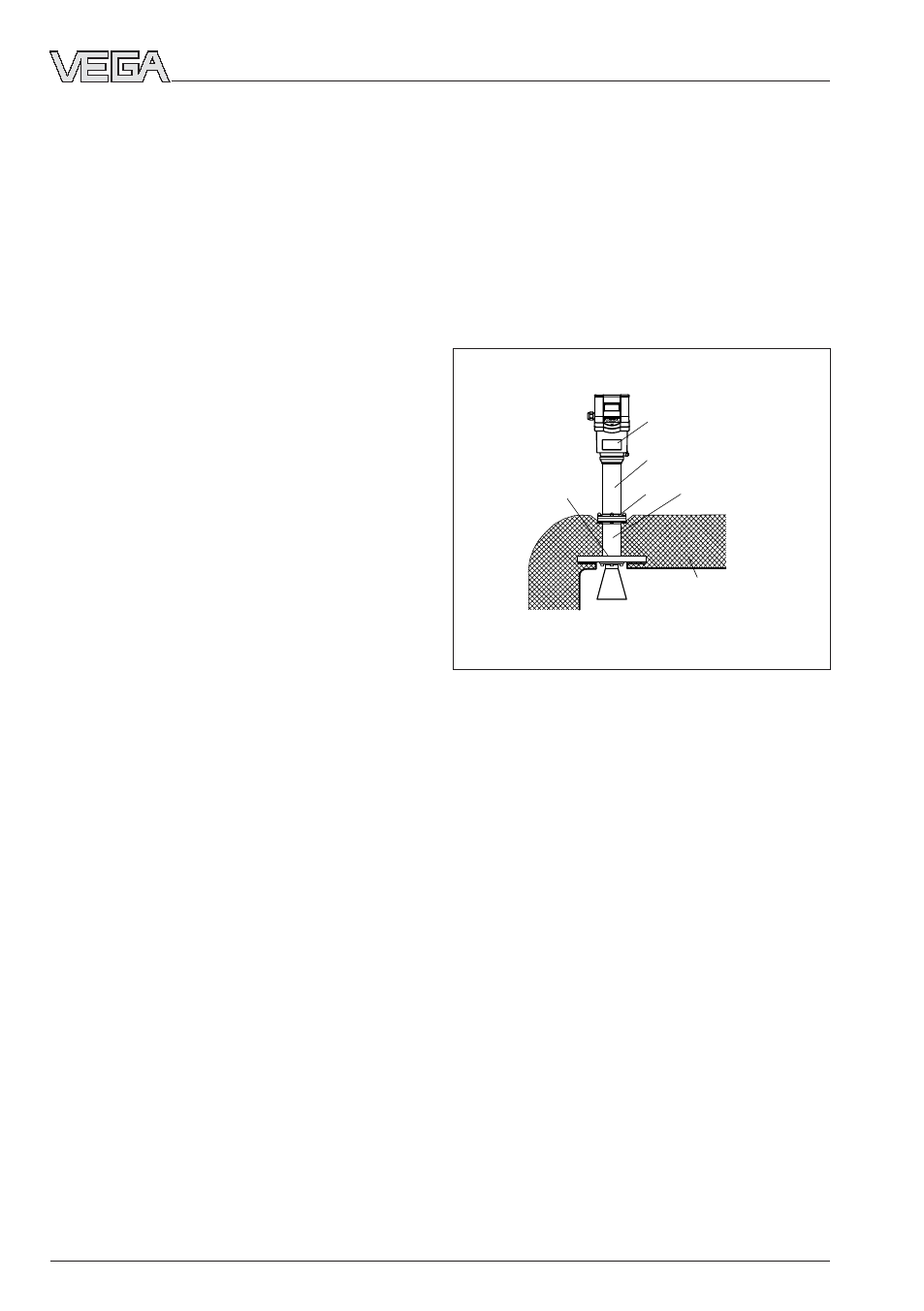

Heat insulation

Heat insulation

In case of process temperature of more than

200°C an insulation on the rear of the flange is

necessary to keep radiated heat away from

the sensor electronics.

The best would be to incorporate the sensor

insulation into the vessel insulation and insu-

late up to approx. the first pipe segment.

40°C

60°C

100°C

240°C

350°C

Vessel insulation

max. 350°C

Emission cone and false echoes

The radar signals are focused by the an-

tenna system. The signals leave the antenna

in a conical path similar to the beam pattern

of a spotlight. This emission cone depends

on the antenna used.

Any object in this beam cone will reflect the

radar signals. Within the first few meters of

the beam cone, tubes, struts or other installa-

tions can interfere with the measurement. At a

distance of 6 m, the false echo of a strut has

an amplitude nine times greater than at a

distance of 18 m.

At greater distances, the energy of the radar

signal distributes itself over a larger area,

thus causing weaker echoes from obstruct-

ing surfaces. The interfering signals are

therefore less critical than those at close

range.

If possible, orient the sensor axis perpen-

dicularly to the product surface and avoid

vessel installations (e.g. pipes and struts)

within the 100% emission cone. If possible,

provide a "clear view“ to the product inside

the emission cone and avoid vessel installa-

tions in the first third of the emission cone.

Optimum measuring conditions exist when

the emission cone reaches the measured

product perpendicularly and when the emis-

sion cone is free from obstructions.

Mounting and installation