6 false echoes, Vessel protrusions – VEGA VEGASON 54K…56K User Manual

Page 30

30

VEGASON 54K … 56K

Mounting and installation

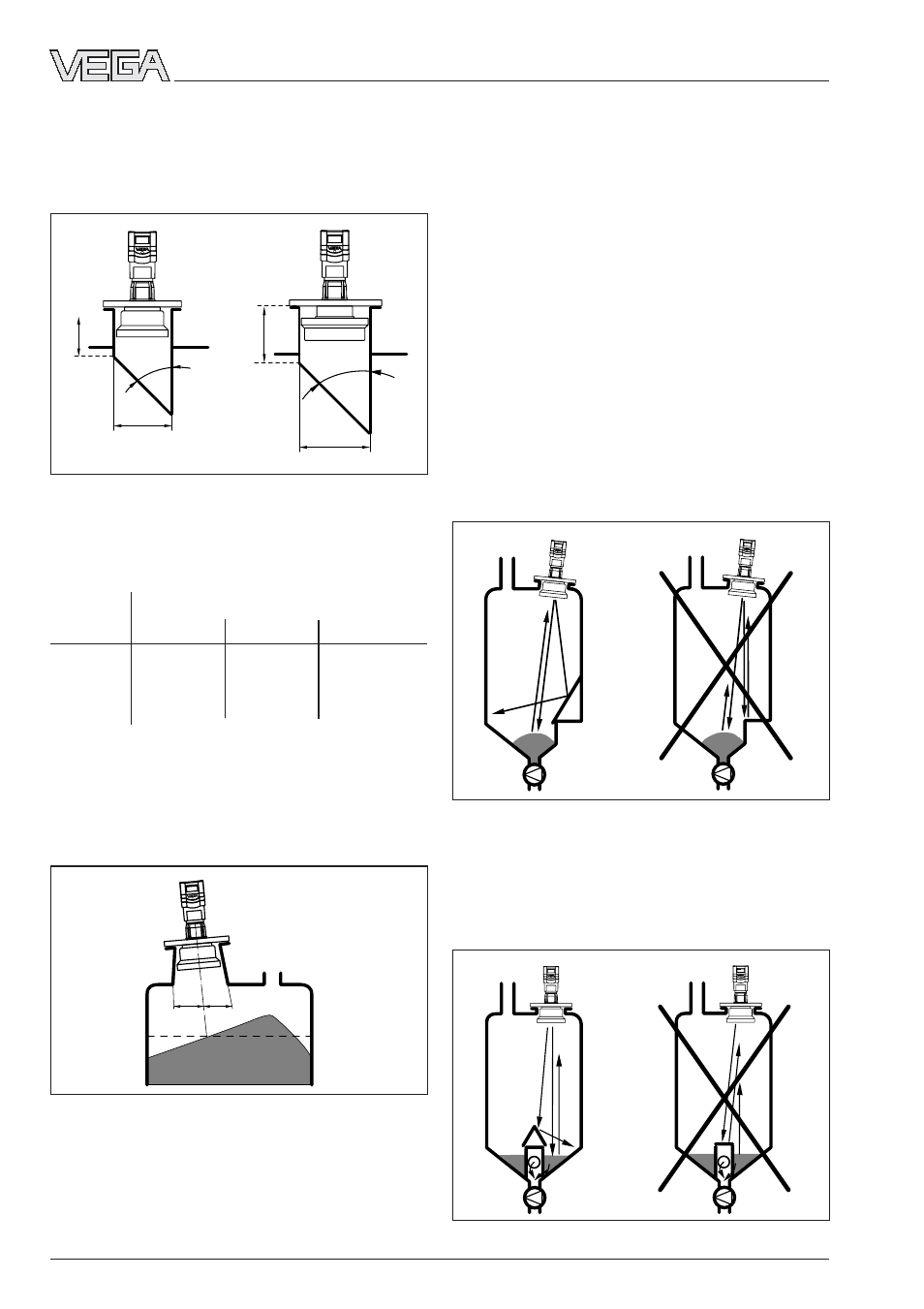

Max. socket length in relation to socket diam-

eter

ø in mm

L in mm

Type 54

Type 55

Type 56

200

400

– –

– –

250

500

500

500

300

– –

– –

600

Socket extensions for solids

For solids, use a conical socket extension

with a taper of at least 15° … 20°.

Socket extensions that do not protrude into the

measured product

ø

45˚

L

ø

45˚

L

Type 54

Type 55

Socket extension in solids

15˚ 15˚

4.6 False echoes

The mounting location of the ultrasonic sensor

must be selected such that no installations or

inflowing material are in the path of the ultra-

sonic impulses. The following examples and

instructions show the most frequent measur-

ing problems and how to avoid them.

Vessel protrusions

Vessel forms with flat protrusions can, due to

their strong false echoes, adversely effect

the measurement. Shields above these flat

protrusions scatter the false echoes and

guarantee a reliable measurement.

Intake pipes, e.g. for the mixing of materials -

with a flat surface directed towards the sen-

sor - should be covered with a sloping

shield. This shield will scatter false echoes.

Vessel protrusions (intake pipe)

Correct

Wrong

Vessel protrusions (slope)

Correct

Wrong

The socket diameter should be as large and

the socket length as small as possible. Make

sure that the socket outlet is burr-free to

minimise false echoes.