VEGA VEGASWING 83 fail safe and signal conditioning instrument VEGATOR 526 Ex User Manual

Page 15

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

15

Mounting

Cable entries

Use cable with round cross section area of

conductor and tighten the cable entry. The

cable entry is suitable for cable diameters

from 5␣ mm to 12␣ mm.

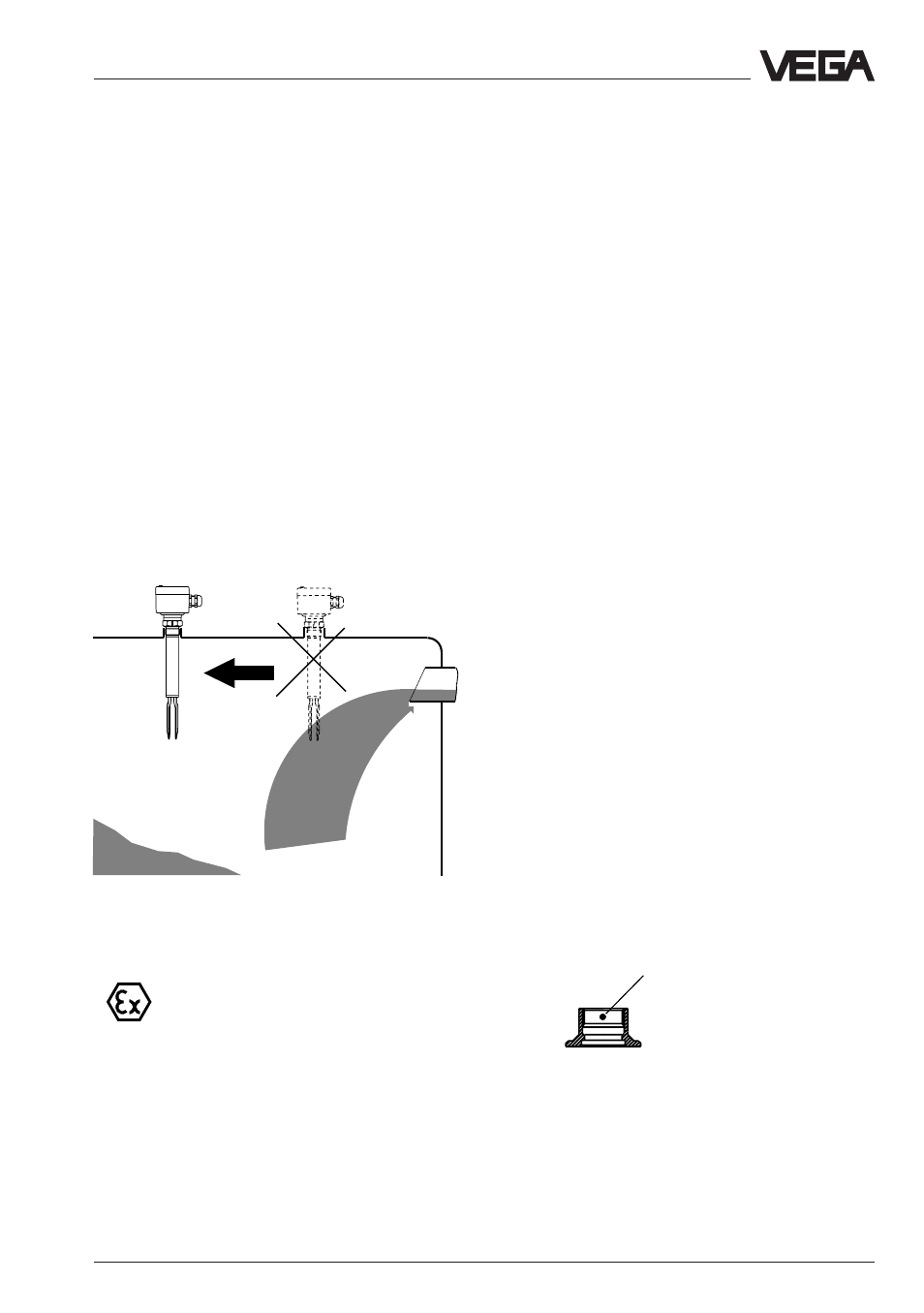

Lateral load

Note that the vibrating element is not

subjected to lateral forces. Mount the

instrument on a position in the vessel where

no interfering influences such as e.g. by

stirrers, filling openings etc. occur. This is

mainly due for instrument types with extension

tube (see fig. 2.5). The surfaces of the tuning

fork should be in parallel to the product

movement so that there is only little resistance

by the tuning fork of VEGASWING in case of

product movements.

VEGASWING with enamel

Treat the instruments with enamel-coating very

carefully and avoid strong shocks or impacts.

Unpack VEGASWING just before mounting.

Insert VEGASWING carefully into the provided

vessel opening and avoid any contact with

sharp-edged vessel parts.

Flow

(e.g. in tubes)

When mounting in tubes or in vessels with

certain flow direction, VEGASWING should be

mounted such that the surfaces of the tuning

fork must be along the flow direction.

Mounting boss

VEGASWING has a defined beginning of

thread. This means that each VEGASWING is

always in the same position after screwing in.

Hence remove the supplied seal from the

thread of VEGASWING. This thread is not

necessary when using a mounting boss.

Screw VEGASWING into the mounting boss.

You can determine the later position of

VEGASWING already before welding (see fig.

2.2). Mark the appropriate position of the

mounting boss. Before welding, you have to

unscrew VEGASWING and remove the rubber

ring from the mounting boss.

Optionally a mounting boss is available which

is already provided with the marking. Weld

this mounting boss with the marking to the top

(see fig. 2.6).

Chemical resistance

For applications in Ex-areas or acc. to

WHG and VbF, VEGASWING must

only be used in liquids to which the

materials of the tuning fork system are

sufficiently chemically resistant.

Fig. 2.5

Fig. 2.6

Marking

(option)