VEGA VEGASWING 83 fail safe and signal conditioning instrument VEGATOR 526 Ex User Manual

Page 14

14

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Pressure

In case of overpressure or gauge pressure in

the vessel, the mounting boss must be sealed

on the thread. Cover the thread with Teflon

tape, hemp etc. or use a seal ring.

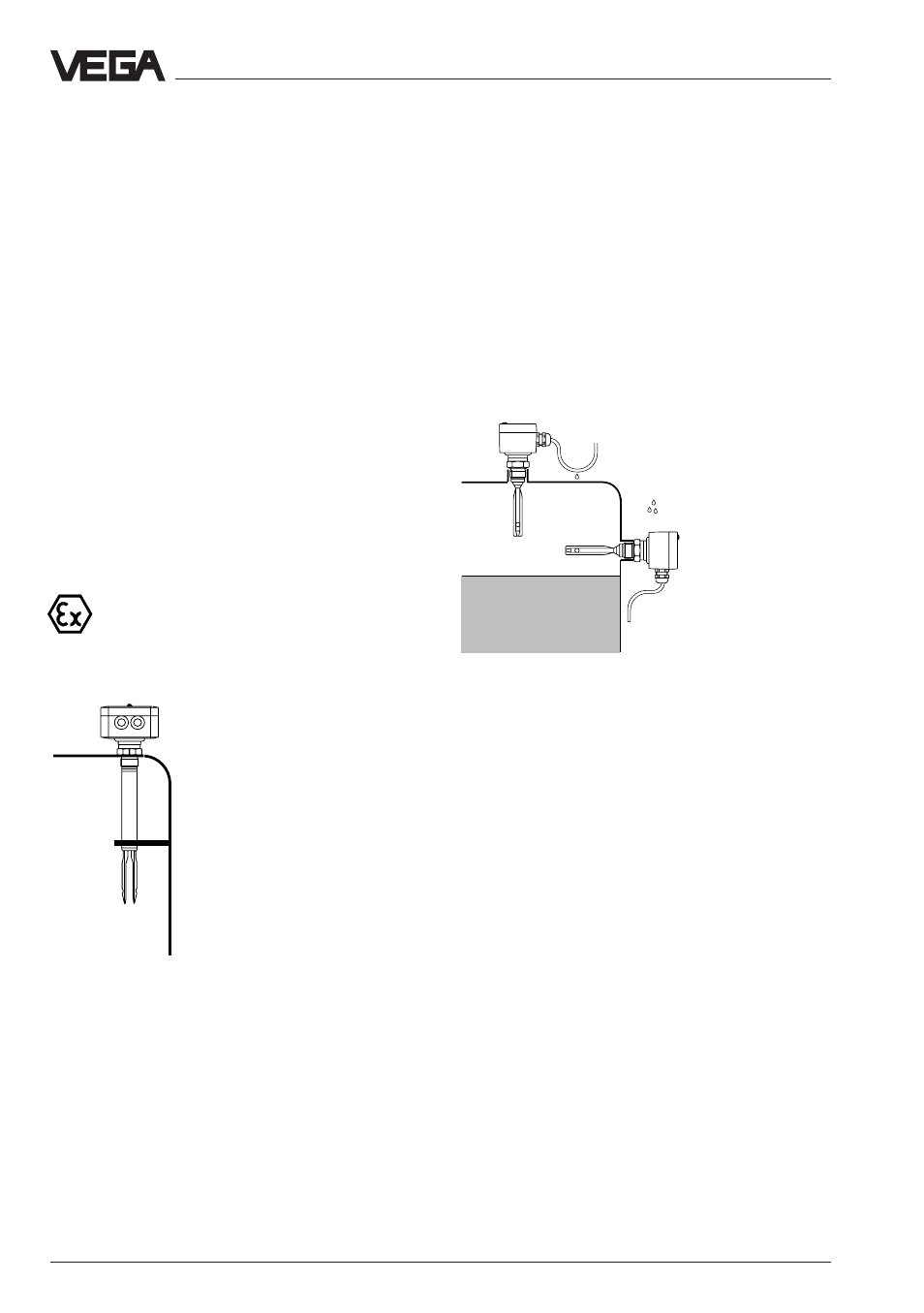

Vibrations

Extreme vibrations and shocks e.g. by stirrers

and turbulences in the vessel can energize

the extension tube of VEGASWING 83 to

resonance frequencies. This causes an

increased wear on the upper weld joint.

Therefore provide a suitable support or fixing

directly above the tuning fork to fasten the

extension tube (see fig. 2.3).

This is mainly valid for applications in Ex-area

zone 0 or acc. to VbF. Note that the tube is not

bent by this measure.

Humidity

Turn the cable entry of horizontally mounted

instruments to the bottom to avoid humidity

ingress. The plastic housing is therefore

rotational by approx. 330

°

. For vertically

mounted instruments loop the connection line

to the instrument housing to the bottom so that

rain and condensation water can drain off.

This is mainly valid for mounting outside, in

humid areas (e.g. by cleaning processes) or

on cooled or heated vessels (see fig. 2.4).

Mounting

Stirrers

Due to stirrers etc. the level switch can be

subjected to strong lateral forces. For this

reason the extension tube of VEGASWING

83␣ W5␣ Ex.C should not be too long, better

check if it is possible to mount a level switch

VEGASWING 81␣ W5␣ Ex.C laterally in horizon-

tal position.

Lockings

For VEGASWING 83…␣ G and 83…␣ N a locking

is available for height adjustment. The switch

point can be adjusted after mounting and

modified afterwards.

Adjust the switch point of the tuning fork to the

requested height. By tightening the pressure

screw you fix the tube to this position.

For pressure applications you have to secure

the pressure screw with the fixing screw.

VEGASWING 83…␣ G and 83…␣ N can be used

in vessels with up to 4␣ bar pressure. Therefore

use the locking (G␣ 1

1

/

2

␣ A,

1

/

2

“␣ NPT) up to 4␣ bar

(ARV2EX0.C…). Note the operating instruction

of the locking.

Fig. 2.3

Fig. 2.4