2 mounting, 1 vegaswing – VEGA VEGASWING 83 fail safe and signal conditioning instrument VEGATOR 526 Ex User Manual

Page 13

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

13

Mounting

2 Mounting

2.1 VEGASWING

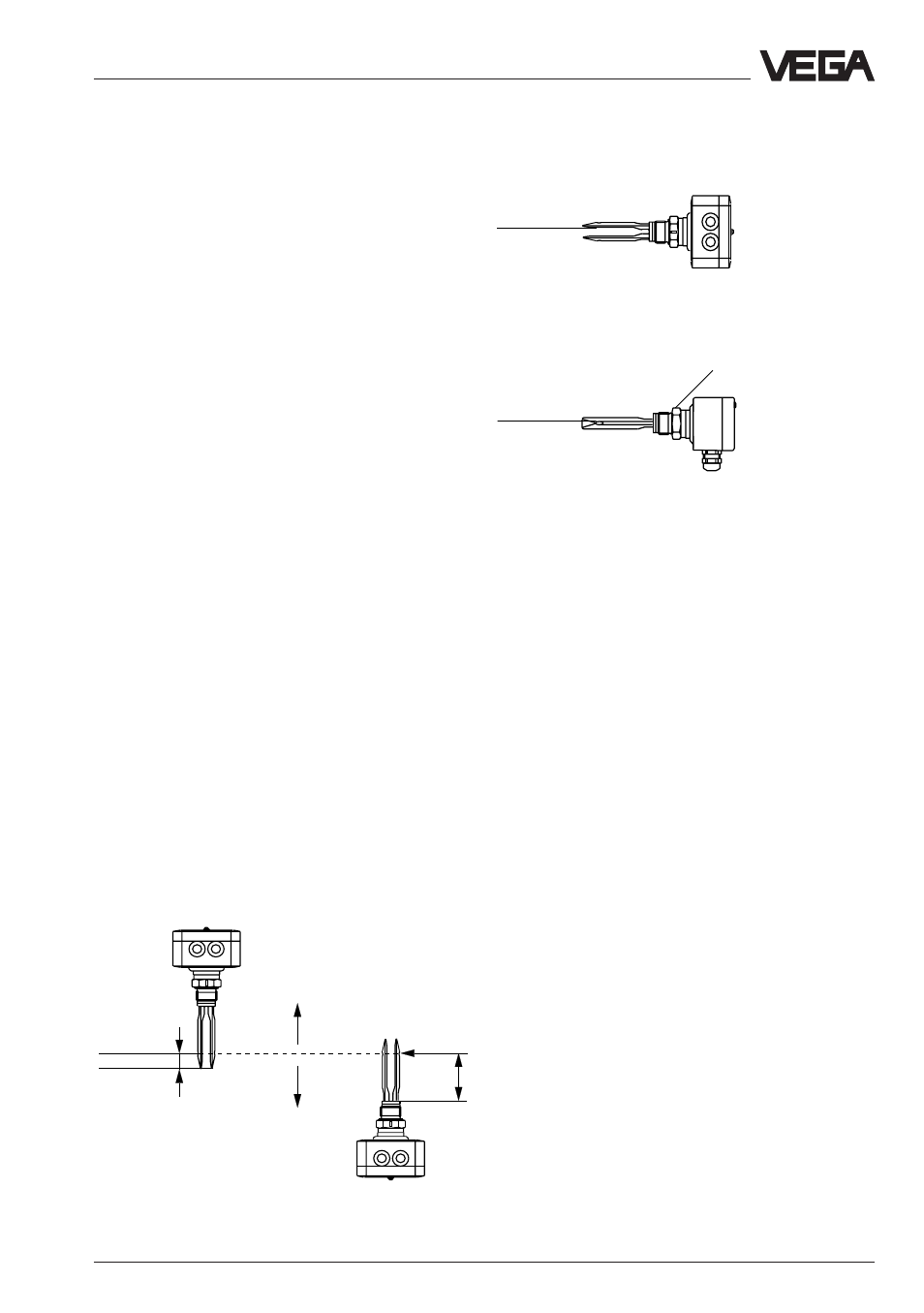

Generally VEGASWING can be mounted in

any individual position. The instrument must

just be mounted such, that the tuning fork is at

the height of the requested switch point.

However note that VEGASWING is only fail

safe as overfill protection (mode A). Note the

following for mounting:

Transport

Do not hold VEGASWING on the tuning fork.

Especially on flange and tube versions the

tuning fork can be damaged by the instrument

weight.

Switch point

Laterally on the tuning fork there are markings

for the switch point in vertical installation in

relation to the medium water. Note when

mounting VEGASWING that the marking is at

the height of the requested level. Note that the

switch point of the instrument is shifted when

the medium has a density deviating from

water (water = 1,0 g/cm

3

). Adjust the

appropriate density range on VEGATOR

526␣ Ex. See also “4.2 Signal conditioning

instrument VEGATOR 526␣ Ex“ (see fig. 2.1).

Vertical mounting

from top, from bottom

Horizontal mounting

Switch

point

Switch

point

Switch point with

higher density

Switch point with

low density

75 mm

approx.

25 mm

recommended installation position for

adhesive products:

Adhesive mediums

For horizontal mounting in adhesive and

viscous mediums, the surface of the tuning

fork should be vertical to reduce build-up on

the fork (see fig. 2.2). The position of the

tuning fork is marked on the hexagon of

VEGASWING. Hence you can check the

position of the tuning fork during mounting.

When the hexagon is placed to the seal, the

thread can be turned by half a turn. This is

sufficient to reach the recommended

installation position.

For adhesive and viscous mediums the tuning

fork should protrude into the vessel to avoid

build-up. Sockets for flanges and mounting

bosses should therefore not exceed a certain

length. With flange versions, the socket

should have a length of max. 40␣ mm, with

threads max. 30␣ mm. The slide switch for the

density adjustment must be set to position 2.

Switch point

Switch point

Marking on top

Fig. 2.1

Fig. 2.2