Quality • integrity • innovation • service – Warrior 30851 - JK 3” Coil Spring Lift Kit (2007 – 2013 Jeep JK Wrangler) User Manual

Page 3

Protecting Your Adventure Lifestyle

========================================================================================

QUALITY • INTEGRITY • INNOVATION • SERVICE

Warrior, Inc.

16850 SW Upper Boones Ferry Rd

Ste. A

Durham, OR 97224

Phone: (888) 220-6861

Fax: (503) 692-0364

[email protected]

www.warriorproducts.com

1. Locate your rear control arms. These are the shorter straight pair of control arms. Left and right sides

are interchangeable, so you just need to be sure the zerks are pointing a direction where you will be able

to access them. Bolt these arms into place re-using the factory mounting hardware. You may need an

assistant to push down on the axle pinion to get your bolt holes to line up, as your new arms are 3/16”

longer than the factory arm.

2. Locate your rear coil springs. Slide these into place, and using the supplied 2_” washer and bolt/nut,

secure the coil spring to the axle. These washers act as a retainer, so the spring cannot fall out of place.

3. Raise the axle to hold the coil springs in place on the upper frame end rubber isolators. Make sure these

are lining up properly as you raise the axle.

4. Locate your rear panhard bar relocation kit.

Follow the instructions included with this kit to install the

bracket.

5. Locate your new anti-sway bar end links. Re-use the axle end hardware to bolt them into place, and then

the new supplied hardware to bolt the upper end in place.

6. Locate your rear shocks, and assemble the boots and decals as you did to the fronts in step 6 of phase 2.

7. On the rear, we use a brake line extension bracket to lower the brake lines, locate this kit. Your brake

line bracket that you unbolted earlier, will bolt to this bracket with supplied hardware, and then the bracket

will bolt into the factory location.

8. You have now completed the rear suspension installation. Double check to ensure that every bolt is

securely tightened, then re-install your tires, remove the jack stands, and lower the vehicle back onto the

ground.

INSTALLATION FINISH CHECKS - Phase 5: Final Prep

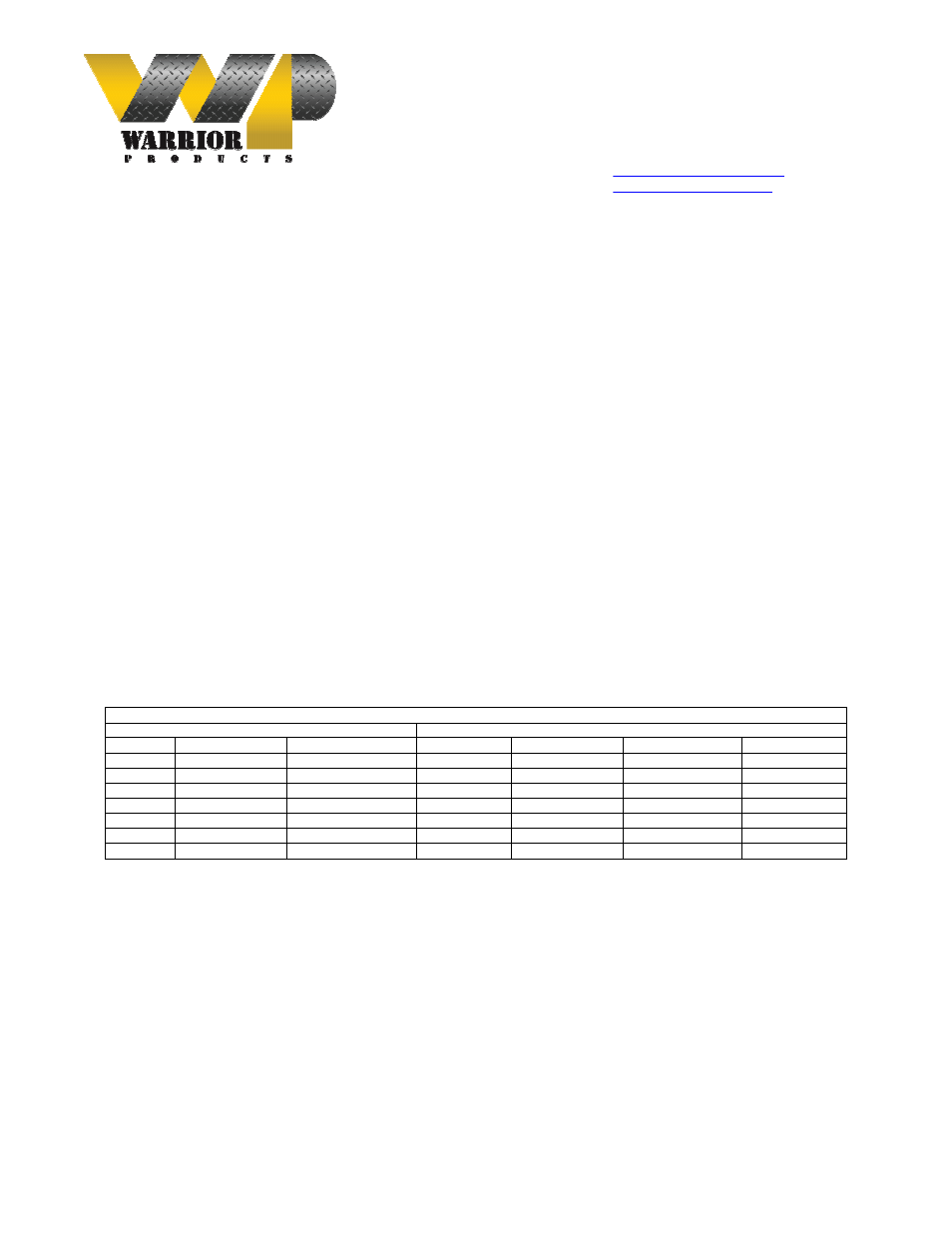

1. It is very important that everything be double checked before driving the vehicle. Start by going thru

every bolt removed and installed, as well as the new bolts added and check for tightness. This chart

makes a good reference for how tight bolts should be.

STANDARD BOLT TORQUE SPECIFICATIONS

INCH SYSTEM

METRIC SYSTEM

Grade 5

Grade 8

Bolt Size

Class 9.8

Class 10.9

Class 12.9

5/16

15 Ft – Lbs

20 Ft – Lbs

M 6

5 Ft – Lbs

9 Ft – Lbs

12 Ft – Lbs

3/8

30 Ft – Lbs

35 Ft – Lbs

M 8

18 Ft – Lbs

23 Ft – Lbs

27 Ft – Lbs

7/16

45 Ft – Lbs

60 Ft – Lbs

M10

32 Ft – Lbs

45 Ft – Lbs

50 Ft – Lbs

_

65 Ft – Lbs

90 Ft – Lbs

M12

55 Ft – Lbs

75 Ft – Lbs

90 Ft – Lbs

9/16

95 Ft – Lbs

130 Ft – Lbs

M14

85 Ft – Lbs

120 Ft – Lbs

145 Ft – Lbs

5/8

135 Ft – Lbs

175 Ft – Lbs

M16

130 Ft – Lbs

165 Ft – Lbs

210 Ft – Lbs

_

185 Ft – Lbs

280 Ft – Lbs

M18

170 Ft – Lbs

240 Ft – Lbs

290 Ft – Lbs

2. Grease all zerks. Your new control arms have a zerk at each end (8 total). Make sure to grease each

one.

3. Check all wheels for tightness. It is very easy to miss tightening a wheel.

4. Adjust your draglink for steering wheel straightness. The rod connecting your pitman arm to your

passenger steering knuckle has an adjuster, held tight by two nuts. You can loosen these nuts and then

simply spin the adjuster. Take some time to get it as straight as possible. If the steering wheel is not

pointing straight when the wheels are pointing straight, the ESP system in your vehicle may malfunction,

causing strange braking issues while driving. (Note: This will not damage your vehicle, but will continue

until the adjustment is made properly) It is strongly suggested that you immediately take your vehicle to a

shop for a professional alignment.

5.

Test drive to check for any vibrations and looseness. If you experience any issues in this regard, return to

your shop immediately and re-check all bolts and nuts.