Pinion assembly – Spicer Drive Axles Service Manual J175-S, J190-S, J210-S, J220-S, J230-SB, W230-S User Manual

Page 15

13

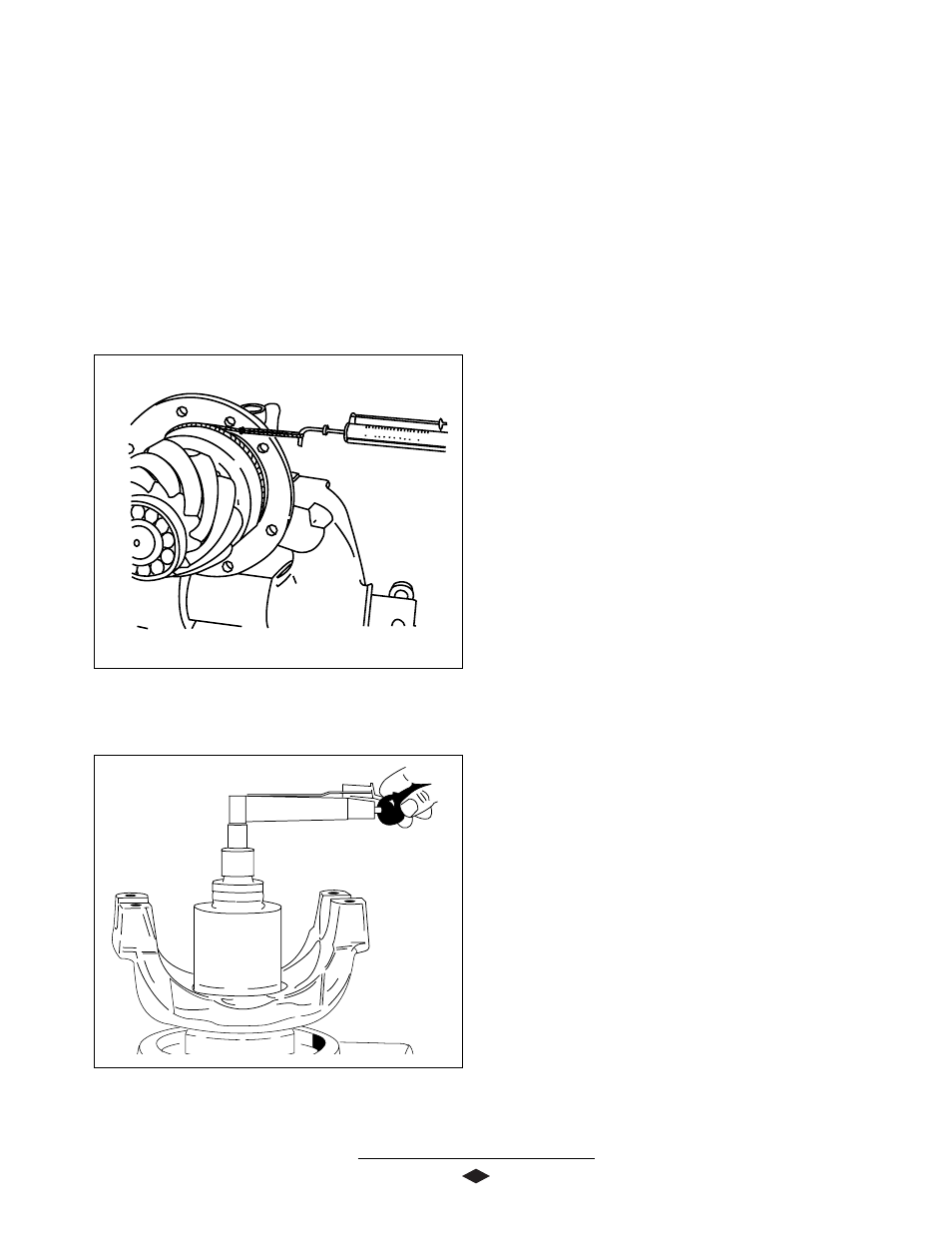

12. Measure torque to rotate with an inch-pound torque

wrench. Torque measurements

should be

taken every fourth revolution and should read

between 10-30

in-lbs of bearing preload.

SeeFigure 9.

NOTE: If bearing preload does not fall within allowed

limits, preload can be increased by using a thinner

spacer and decreased by using a thicker spacer.

.001" change in preload spacer thickness will change

torque to rotate approximately 30 in-lbs.

NOTE: Individual carriers may vary slightly.

Pinion bearing preload spacers are available in several

thicknesses. Refer to service parts booklet for kits of

commonly used preload spacers.

Always measure each spacer before assembly to ensure

correct thickness.

NOTE: Closer adjustment can be made by sanding the

next thicker spacer to desired thickness using emery

cloth on a flat surface.

CAUTION: Wash spacer thoroughly of emery

cuttings before installing on pinion.

NOTE: Spicer recommends that new torque prevailing

nuts be used.

13. Apply Loctite #680(green) to threads.

14. Install new pinion oil seal. Apply a small amount of

light grease to the seal lip. Prior to installing yoke.

15. Use torque multiplier and torque flanged hex nut to

900-1,200 Lb-Ft (1,220-1,627 N-m).

Pinion Assembly Complete

PINION ASSEMBLY

To measure preload with spring scale, clamp the end

yoke horizontally in a soft-jawed vise. Attach one end of

cord to a bolt hole in the pinion bearing cage and

attach the other end of the cord to the spring scale.

Rotate pinion cage and attach the other end of cord to

the spring scale. Rotate pinion bearing cage by pulling

scale. Read scale during fourth revolution. Scale

reading must be between 3-9 lbs.

See Figure 8.

Figure 8

Figure 9