Pinion removal – Spicer Drive Axles Service Manual J175-S, J190-S, J210-S, J220-S, J230-SB, W230-S User Manual

Page 12

10

3. Holding yoke stationary, remove flanged hex nut

and washer. Use of a torque multiplier may be

necessary.

4. Remove the end yoke using a suitable puller. See

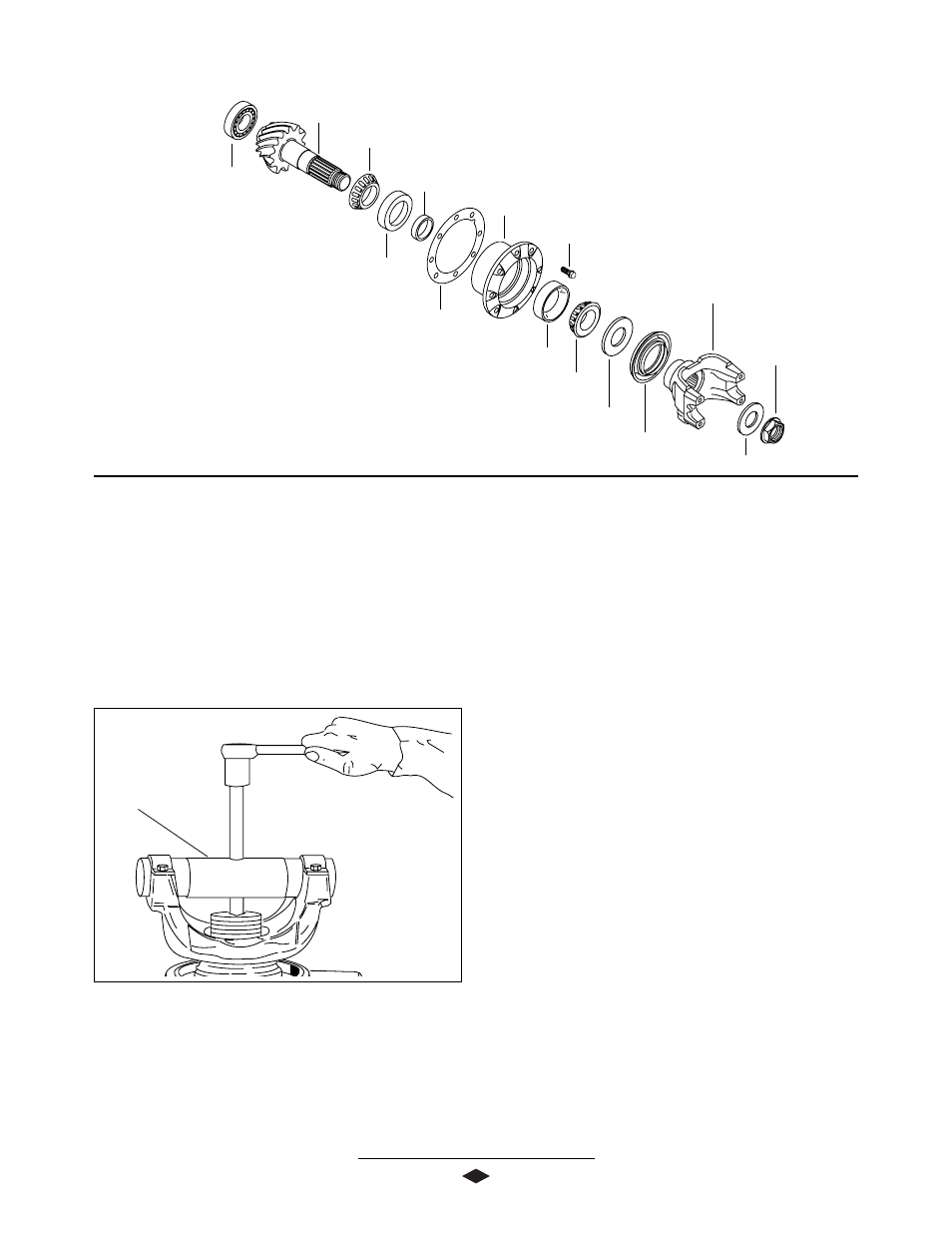

PINION REMOVAL

1. Remove pinion bearing cage mounting bolts.

2. Remove pinion and cage assembly from carrier

housing. If difficulty is encountered in removing

pinion assembly from carrier housing, place brass

drift on inner end of pinion and tap lightly.

NOTE: Retain shims for possible use during

reassembly.

Flanged Hex Nut

(900-1,200 Lb-Ft)

(1,220-1,627 N-m)

End Yoke Assembly

Bearing Preload Spacer

Pinion Oil Seal

Outer Pinion Bearing Cup

Outer Pinion Bearing Cone

Pinion Bearing Cage Bolt

(160-180 Ft-Lb)

(217-244 N-m)

Pinion Bearing Cage

Pinion Position Shim(s)

Inner Pinion Bearing Cup

Pinion Bearing Spacer (Selective)

Pinion

Pinion Pilot Bearing

Figure 5

Yoke Puller

Figure 5.

5. Remove pinion from cage assembly.

6. Remove bearing preload spacer and save for use in

reassembly.

7. Remove the old pinion seal and discard. Always

replace it with a new seal at the time of reassembly.

8. Lift out outer pinion bearing cone.

9. Remove inner pinion bearing cup, using a suitable

adapter and press or puller.

CAUTION: Do not nick bearing bore.

10. Remove outer pinion bearing cup, using same

procedure as step 9.

11. Remove pinion pilot bearing from end of pinion.

12. Remove inner pinion bearing cone from pinion.

Pinion Removal Complete

Inner Pinion Bearing Cone

Washer

NOTE: Torque specifications, shown

on illustration, apply only to J Model.

See Page 21 for W Model torque

specifications.