MSD 62153 DIS-4 Plus High Output Installation User Manual

Page 3

INSTALLATION INSTRUCTIONS

3

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

SPARK PLUGS AND WIRES

Spark plug wires are very important to the operation of the DIS Series Ignition. A good quality, helically

wound wire and proper routing are required to obtain the best performance from the ignition. MSD

recommends using a helically wound suppression type wire such as the MSD 8mm Heli-Core or 8.5mm

Super Conductor Spark Plug Wire.

This type of wire provides a good path for the spark to follow while keeping Electro Magnetic Interference

(EMI) to a minimum. Excessive EMI, such as the amount that is produced by solid core spark plug wires,

will interfere with the operation of the MSD or other electronics on the vehicle.

NOTE: Solid Core spark plug wires cannot be used with an MSD Ignition.

Routing: Correct routing of the plug wires is also important to performance. Wires should be routed

away from sharp edges and engine heat sources. If there are two wires that are next to each other in

the engine's firing order, the wires should be routed away from each other to avoid inducing a spark

into the other wire.

To add more heat protection to the wires, MSD offers Pro Heat Guard, PN 3411. This is a glass woven

and silicone coated protective sleeve that can be slid over the plug wires. For extra protection to the

spark plug boots, MSD also offers Pro-Boot Guard, PN 3412.

Spark Plugs: Choosing the correct spark plug design and heat range is important when trying to get

the best performance possible. Since there are so many engine combinations and manufacturers,

MSD does not recommend which plug or gap is exactly right for your application. Platinum style spark

plugs are not recommended. MSD suggests that you follow the engine builder or manufacturer’s

specification for spark plugs. With that, you can then experiment with the plug gap to obtain the

best performance. The gap of the plugs can be opened in 0.005” increments, then tested until the

best performance is obtained. MSD judges the plug gap by compression and other variables. Every

application is different and should be tested and tuned.

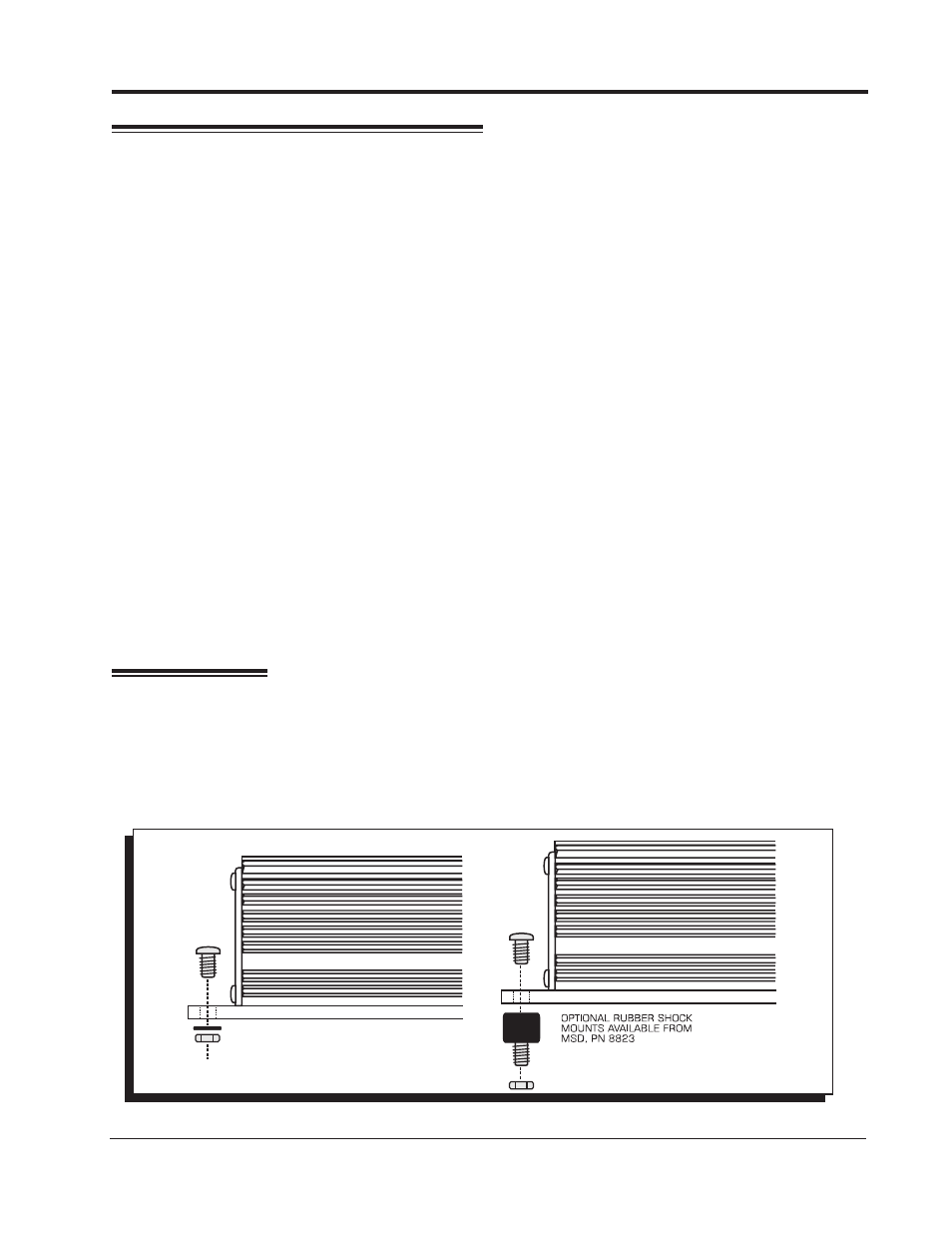

MOUNTING

The MSD Ignition may be mounted in any location except on the engine or near the exhaust manifold.

Excessive heat at these locations may cause damage to the ignition. It is not recommended to mount

the unit in an enclosed area such as the glovebox. When selecting a mounting location, make sure

the cable harness will reach the battery and coils and the programming dial are accessible. When

a suitable location is found, hold the ignition in place and mark the location of the mounting holes.

Using a 13/64” drill bit, drill a hole in each of the locations marked and use the supplied hardware

screws to mount the ignition unit (Figure 1).

Figure 1 Mounting the DIS Ignition.