Bosch PFS 105 E WALLPaint User Manual

Page 19

English | 19

Bosch Power Tools

1 619 929 K18 | (18.11.11)

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Our customer service representatives can answer your ques-

tions concerning possible applications and adjustment of

products and accessories.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: +44 (0844) 736 0109

Fax: +44 (0844) 736 0146

E-Mail: [email protected]

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: +353 (01) 4 66 67 00

Fax: +353 (01) 4 66 68 88

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: +61 (01300) 307 044

Fax: +61 (01300) 307 045

Inside New Zealand:

Phone: +64 (0800) 543 353

Fax: +64 (0800) 428 570

Outside AU and NZ:

Phone: +61 (03) 9541 5555

www.bosch.com.au

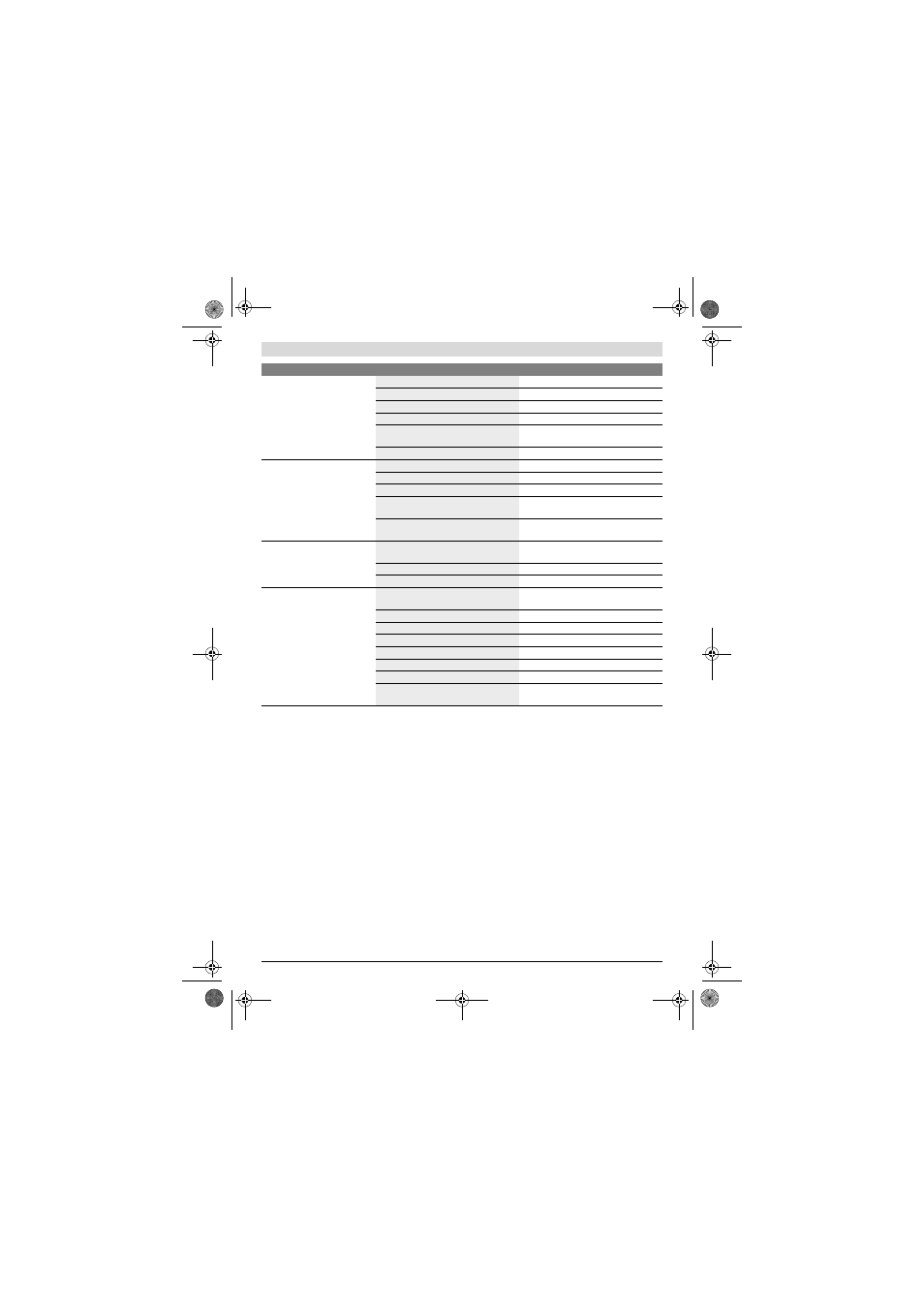

Atomisation too course

Spraying capacity too high

Turn thumbwheel 7 in direction I

Air flow too low

Turn control knob 24 toward the right

Nozzle needle 16 soiled

Clean nozzle needle

Too little pressure build-up in container 10 Screw container firmly against spray gun

Spray material too viscous

Dilute the spray material again and carry out

a test-spray run

Air filter 29 heavily soiled

Change the air filter

Spray jet pulsates

Not enough spray material in container

Refill spray material

Venting hole on suction tube 12 clogged

Clean suction tube and hole

Air filter 29 heavily soiled

Change the air filter

Spray material too viscous

Dilute the spray material again and carry out

a test-spray run

Nozzle seal 17 missing or incorrectly

mounted

Mount nozzle seal into spray gun (groove

must face away from the spray gun)

Spray material drips from the

nozzle

Deposits of spray material on nozzle needle

16 and air cap 3

Clean nozzle needle and air cap

Nozzle needle 16 worn

Replace nozzle needle

Nozzle loose

Tighten union nut 5

No spray material emerges from

the nozzle

Control knob for air flow 24 not set to “maxi-

mum air flow”

Set control knob for air flow 24 to “maximum

air flow”

No pressure build-up in container 10

Screw container firmly against spray gun

Suction tube 12 loose

Insert suction tube properly

Nozzle needle 16 clogged

Clean nozzle needle

Suction tube 12 clogged

Clean suction tube

Venting hole on suction tube 12 clogged

Clean suction tube and hole

Container seal 13 missing or damaged

Slide (new) container seal over suction tube

Spray material too viscous

Dilute the spray material again and carry out

a test-spray run

Problem

Cause

Corrective Measure

OBJ_BUCH-1543-001.book Page 19 Friday, November 18, 2011 9:16 AM