Maintenance and service – Bosch PFS 105 E WALLPaint User Manual

Page 18

18 | English

1 619 929 K18 | (18.11.11)

Bosch Power Tools

– For lifting or transporting the fine-spray system, use the

carrying handle 27.

Maintenance and Service

Maintenance and Cleaning

f

Before any work on the machine itself, pull the mains

plug.

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

If the replacement of the supply cord is necessary, this has to

be done by Bosch or an authorized Bosch service agent in or-

der to avoid a safety hazard.

Cleaning the Spray Gun (see figure I)

Proper cleaning is the requirement for flawless operation of

the spray gun. Improper or lack of cleaning voids warranty

claims.

Always clean the spray gun and the container for the spray

material with water.

Never immerse the complete spray gun in water.

Never clean the nozzle and air holes of the spray gun with

pointed metal objects.

– Switch the base unit off and pull the trigger switch 9 of the

spray gun so that the spray material can flow back into the

container.

– Unscrew the container 10 and empty the remaining spray

material.

– Fill water into the container and screw it to the spray gun.

– Shake the spray gun several times.

– Switch the base unit on and spray the water into a suitable

collecting container (e.g. a bucket).

– Repeat the last three steps until only clear water comes out

of the spray gun.

– Switch the base unit off again.

– Completely empty the container 10.

– Check if the suction tube 12 and the container seal 13 are

free of spray material and undamaged.

– Clean exterior parts of the container and the spray gun

with a moist cloth.

– Unscrew the adjusting ring 4, the union nut 5, the air cap 3

and the rotating ring 14.

– Clean the nozzle cap 15 and the nozzle needle 16 with wa-

ter.

– Mount the nozzle cap 15 to the spray gun body and turn it

to the correct position.

– Mount the rotating ring 14 and the air cap 3 to nozzle cap

15 and tighten all parts with union nut 5.

– Attach adjusting ring 4 onto union nut 5.

Changing the Air Filter (see figure J)

The air filter must be replaced when soiled.

– Remove the air filter cover 23.

– Replace the air filter 29.

– Remount the air filter cover.

Cleaning the Nozzle Seal (see figure K)

The nozzle seal 17 must be cleaned occasionally.

– Remove the nozzle cap 15 and the nozzle seal 17.

If required, use a pointed object, as the nozzle seal is seat-

ed firmly to the spray gun.

– Clean the nozzle seal with water.

– Reinstall the nozzle seal in the spray gun. Pay attention that

the groove points away from the spray gun.

Material Disposal

Paint and dried paint remainders must be disposed of in an

environmentally-friendly manner. Observe the manufactur-

er’s instructions for disposal and the local regulations for haz-

ardous waste disposal.

Chemicals harmful to the environment may not be disposed

of into soil, groundwater or bodies of water. Never pour

chemicals harmful to the environment into the sewerage sys-

tem!

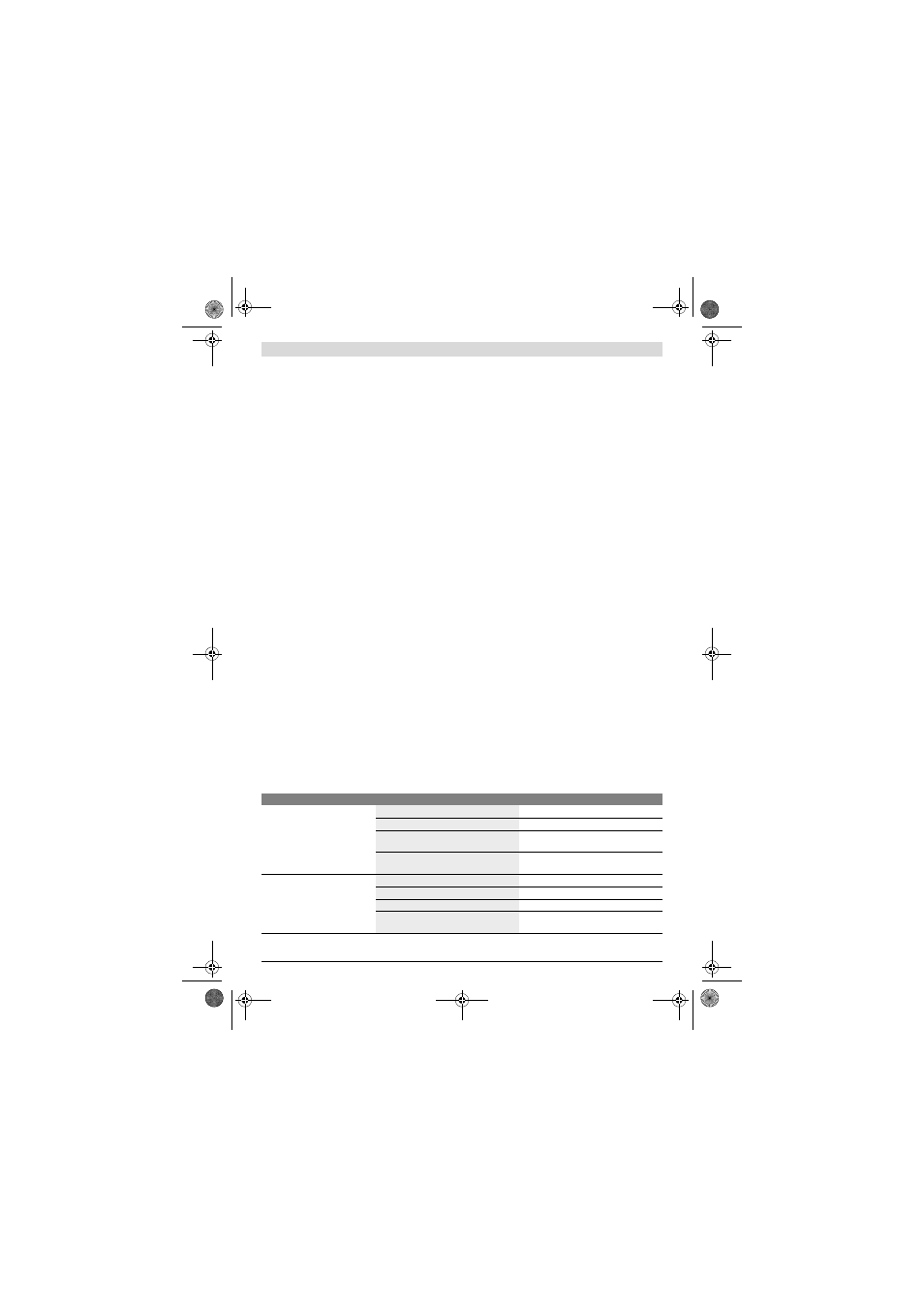

Correction of Malfunctions

Problem

Cause

Corrective Measure

Spray material does not cover

properly

Spraying capacity too low

Turn thumbwheel 7 in direction IIII

Clearance to target area too large

Reduce spray distance

Not enough spray material on target area,

too few spray paths sprayed over target area

Apply more spray paths over target area

Spray material too viscous

Dilute the spray material again and carry out

a test-spray run

Spray material runs off after coat-

ing

Too much spray material applied

Turn thumbwheel 7 in direction I

Clearance to target area too close

Increase spray distance

Viscosity of spray material too low

Add original spray material

Spray material applied too often over same

spot

Remove spray material; reduce number of

spray paths over same spot

OBJ_BUCH-1543-001.book Page 18 Friday, November 18, 2011 9:16 AM