Maintenance and service – Bosch GFF 22 A Professional User Manual

Page 18

18 | English

1 609 929 N81 | (18.5.11)

Bosch Power Tools

– Longitudinal and lateral joints: With the angle stop, see

figure G; with the adjustable height stop, see figure H

– Frame joints: See figure I

– Centre wall joints: See figure J

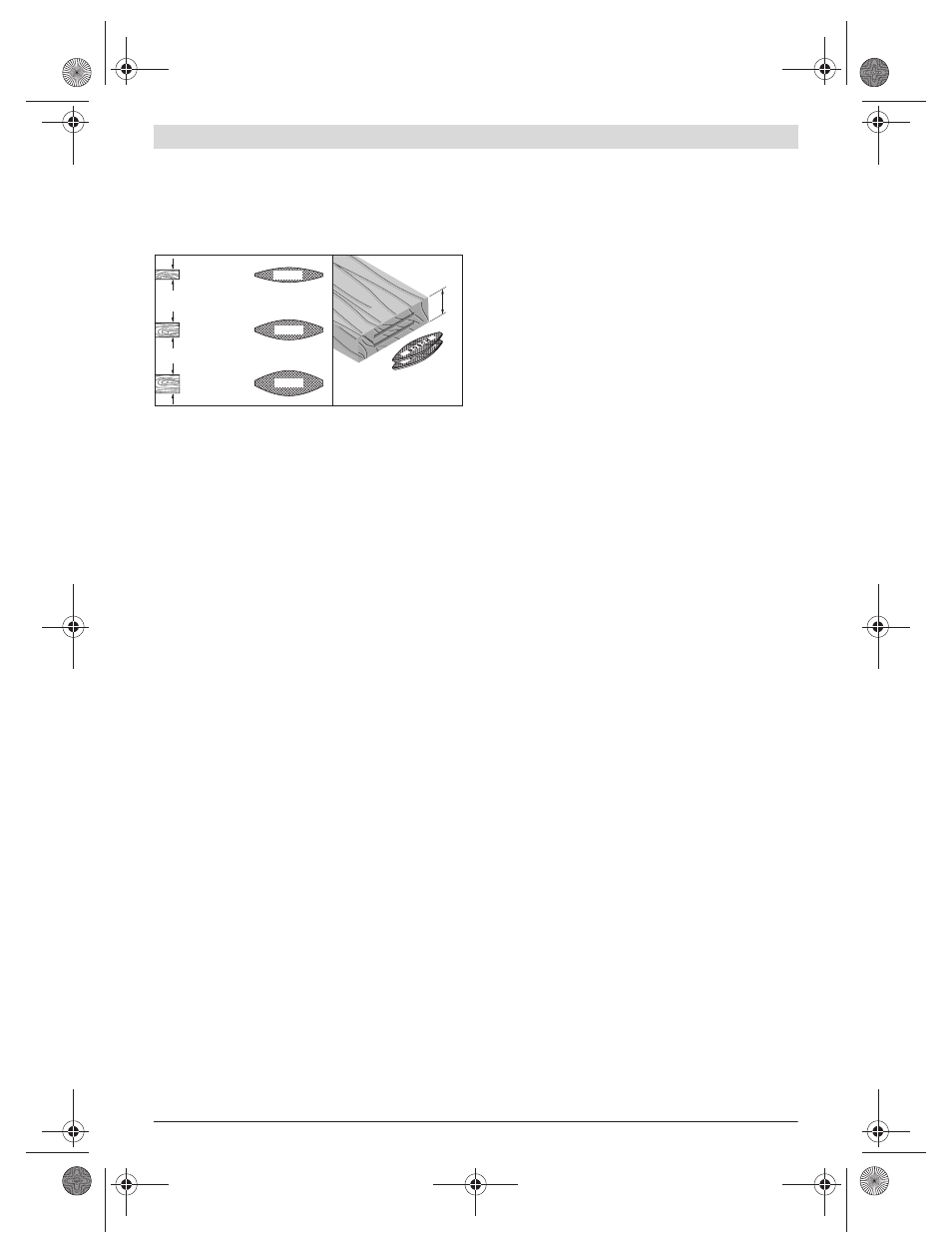

Selection of the Biscuit Dowel

Use the largest possible biscuit for a solid wood joint. Bosch

offers appropriate biscuits in the accessories program (see

accessories page at the end of the operating instructions).

Cutting Thin Workpieces (see figure K)

For cutting workpieces with a thickness below 16 mm, place

the attachment plate 16 on the angle stop 17. This ensures

that the groove is not cut too close to the upper surface of the

workpiece. When calculating the horizontal cutting position,

consider the 4 mm thickness of the attachment plate.

Also use the attachment plate 16 for mitre joints in thin work-

pieces so that the groove is not cut too deep.

Cutting Narrow Workpieces

If possible, use the adjustable height stop 9 when cutting nar-

row workpieces. Pay attention that the marks for the maxi-

mum cutting disc width 10 on the height stop are within the

workpiece.

Maintenance and Service

Maintenance and Cleaning

f

Before any work on the machine itself, pull the mains

plug.

f

For safe and proper working, always keep the machine

and ventilation slots clean.

Clean and grease the guides as necessary. Use exclusively

non-gumming oil for this (e.g., sewing machine oil).

Re-tensioning Clamping Levers

The tensioning force of the clamping levers 3 and 12 can be

readjusted, if required. For this, loosen and then screw off the

clamping lever. Screw on the clamping lever again displaced

by at least 30° in anticlockwise direction.

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Our customer service representatives can answer your ques-

tions concerning possible applications and adjustment of

products and accessories.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: +44 (0844) 736 0109

Fax: +44 (0844) 736 0146

E-Mail: [email protected]

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: +353 (01) 4 66 67 00

Fax: +353 (01) 4 66 68 88

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: +61 (01300) 307 044

Fax: +61 (01300) 307 045

Inside New Zealand:

Phone: +64 (0800) 543 353

Fax: +64 (0800) 428 570

Outside AU and NZ:

Phone: +61 (03) 9541 5555

www.bosch.com.au

Republic of South Africa

Customer service

Hotline: +27 (011) 6 51 96 00

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: +27 (011) 4 93 93 75

Fax: +27 (011) 4 93 01 26

E-Mail: [email protected]

8–12 mm

>25 mm

12–15 mm

>15 mm

0

10

20

OBJ_BUCH-268-003.book Page 18 Wednesday, May 18, 2011 11:03 AM