ACU-RITE ENC 250SS User Manual

Page 9

Acu-Rite Companies Inc.

ENC 250™

SINGLE SECTION

Encoder Installation Procedure

7

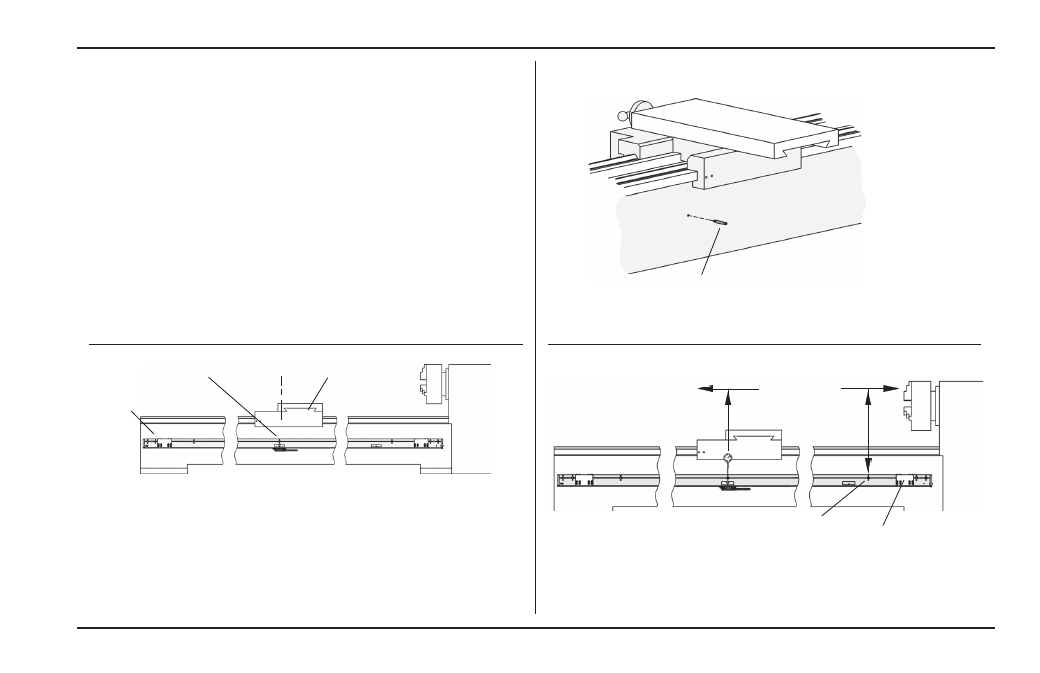

• Move the machine axis to its center of travel.

• Hold the encoder to the intented mounting location, and

position for the required clearances. Allow minimal

distance required for the reading head brackets.

• Mark the “most centered” scale mounting hole location to

the machine with a center punch.

• Remove encoder, drill / tap location for a [1/4-20 x 1/2”] M6

x 12mm deep.

These steps apply to all mounting conditions. Although this

may not pictorially represent your application, your

installation procedure should follow these steps.

• Adjust drill depths and fastener lengths as required.

• When instructed on page 10, adjust the leveling set screws

as follows:

1. Insert, but do not tighten the [8-32] 4mm reading head

screws.

2. Use a [.001-.003”] .025 - .076mm shim between the

leveling set screws and mounting surface.

3. Adjust each set screw until a slight drag is felt on the

shim.

4. Evenly tighten the [8-32] 4mm reading head mounting screws.

• Contact your Authorized Distributor should you require

additional assistance.

CL

Movable axis

(carriage)

Most centered scale

mounting hole

Encoder

• Attach the 1/4-20 installation stud tool.

• Slide the scale case onto the stud at the same hole location.

Stud tool

The stud tool is used

temporarily to support

the encoder while

locating the mounting

holes

• Align the top of the scale case.

• Transfer punch the furthest right mounting hole location

before the expansion cover.

• Allow the scale to swing down, drill / tap location for a [1/4-

20 x 1/2”] M6 x 12mm deep.

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Right expansion cover

Axis Travel

Hole location